Dialysis: A Marriage of Thermal Management and Pressure Sensing

The second installment in our six-part series on platform sensors covers the role of pressure sensors in dialysis machines.

March 26, 2013

Thermal management solutions and pressure sensors work together in dialysis machines to deliver fluid to the patient at body temperature, which is critical to the patient's safety. Selecting a heater assembly and pressure sensor from a single component manufacturer, instead of sourcing multiple thermal technologies and sensors from different suppliers, streamlines manufacturing and the supply chain. It can also simplify assembly, reduce design time, and free up developers to work on other systems. A platform sensor also helps in system qualification by providing a complete assembly that meets regulatory requirements.

|

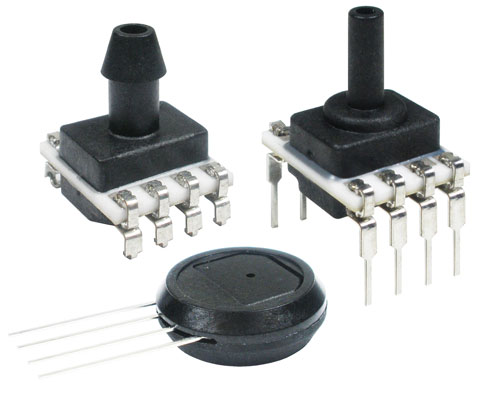

Honeywell TruStability HSC/SS – 26PC Liquid Media Compatible sensors allow customers to use one port of the sensor with condensing humidity or non-corrosive liquid media, such as de-ionized water, eliminating the complexity and expense of having to protect the sensor from this type of media. |

Heater assemblies warm the blood or dialysate to body temperature prior to reentry into the patient. The heater control needs to precisely control the dialysate temperature. Board-mount pressure sensors measure the rate of fluids leaving and entering the patient. They obtain dialysate and venous pressure measurements without interrupting the flow.

Using a combination of temperature sensors and thermostats, heater assemblies should provide several heating technologies and materials that are essential to accommodate different dialysis equipment designs. These designs often require heater assemblies of different sizes and temperatures, which impact the type of thermal technology required.

Heater assemblies should offer a variety of sizes, wattages, mounting options, temperature monitoring, and temperature control capabilities. A variety of configurations (flat, transparent composite, and high temperature) and manufacturing materials (silicon, kapton, polyester indium tin oxide, and other dielectrics) provide more options within an application.

Precisely and accurately measuring dialysate and venous pressure is critical to a patient's safety during dialysis treatment. The pressure sensor needs to provide accurate pressure monitoring of fluid and blood flow to help maintain pressure in the desired range. This ensures there isn't an over- or under-pressure situation, which can result in either blood vessels bursting or air bubbles in the line.

The best way to get an accurate, precise, and better response time to changes in the system is by placing the sense element as close to the liquid as possible. This calls for pressure sensors that provide liquid media compatibility, which can eliminate design complexity and avoid costs related to protecting the sensor.

Additionally, pressure sensors should provide multiple mounting options to fit a variety of applications. As an example, by providing cable assembly options, a sensor platform can accommodate mounting in remote locations or in space-constrained applications. This allows the designer to put the sensor exactly where it needs to be for accurate and precise measurements.

A.J. Smith is director of product marketing at Honeywell Sensing and Control, where he is responsible for leading, managing, and directing all product-marketing-related activities within the pressure and thermal business. He holds a bachelor's degree in chemistry from the University of Illinois at Urbana-Champaign and received his MBA from the University of Minnesota Twin Cities campus with specializations in finance, strategic management, and international business. He can be reached at [email protected].

Related Content

Platform Sensors Enable Design for Flexibility

How Platform Sensors Can Help Developers of Ventilators and Anesthesia Systems

How Sensors Assist Surgeons in Eye Surgery

Wound Therapy: Using Pressure Sensors to Measure Vacuum

Three Critical Factors for Force and Pressure Sensors in Infusion Pumps

Platform Sensors Fulfill High Sensitivity and Repeatability Requirements for Analytical Instruments

About the Author(s)

You May Also Like