Can Next-Gen Sensors Transform Surgical Robotics and Other Precision Medical Devices?

A webinar series explores how sensors and electronics can be used for demanding medtech applications.

February 18, 2021

Today’s surgeons demand medical devices that allow precise, repeatable movement and control, often in a compact footprint. Force and torque sensors along with advanced electronics can help deliver such capabilities, but device developers can encounter engineering challenges, particularly for surgical robotics. For instance, measuring the force or torque moment is critical to ensuring that robotic tools can perform with precise and seamless movements, but there can be challenges incorporating sensors into complex medical systems, according to FUTEK Advanced Sensor Technology Inc.

To help engineers, FUTEK, a maker of load cells, torque sensors, pressure sensors, multi-axis sensors, and software, is offering a free 3-day online course entitled, “For Good Measure – How Advanced Sensor & Electronics Solutions Are Shaping Medtech Innovation.”

“With this web series we’re hoping to make life easier for engineers who work on complex medical applications. These kinds of projects are demanding; deadlines are tight, and we often see how theoretical assumptions about measurement end up requiring redesign and reconfiguration within very compromised timelines. We hope that engineers can begin thinking about measurement technology beyond a single component and see how a sensor system design is required to solve their needs,” Navid Mokhberi, vice president at FUTEK Advanced Sensor Technology Inc., told MD+DI.

Broadcast on February 23-25, the webinars aim to help attendees:

• Get an overview of the technology behind sensors and electronics used for demanding medtech applications

• Learn how development of miniature force and torque sensors are allowing for new measurement possibilities

• Understand how the design and integration of electronics can maximize the performance of your output

• Get insights into what's next in cutting-edge measurement technology

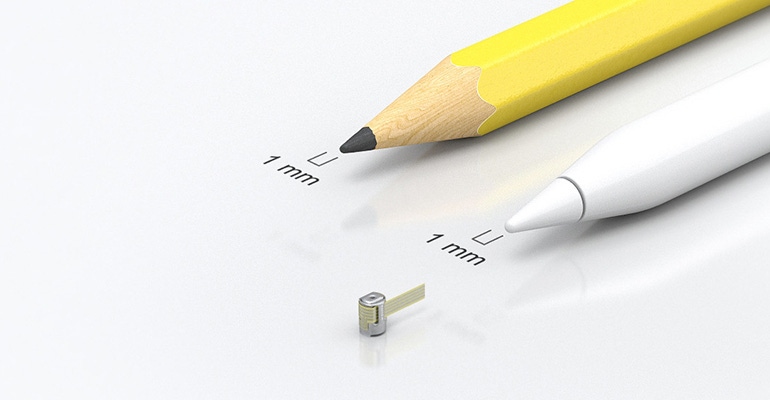

The first session, “Small Talk – Developing Miniaturized Sensors for the Future of MedTech,” will explore how sensor miniaturization is enabling advances in the rapidly evolving field of surgical robotics. In this presentation, Principal Engineer Maciej “MJ” Lisiak discusses the challenges and breakthroughs in the development of FUTEK’s Nano sensor, the smallest force measurement solution of its kind (shown above).

In the second session, “Precision at Every Turn – Why Torque Sensors Are Critical for MedTech Applications,” FUTEK’s Application group will explore the fundamentals of rotary and reaction torque technology and discuss how FUTEK has developed industry-leading solutions to address torque measurement challenges. Speaker Ehsan Mokhberi, director of business development, FUTEK, will examine how these sensors can be put to use in advanced robotic surgery applications and could help drive future medtech innovation.

And in the third and final session, “Lowering the Noise – How Advanced Electronics Optimize Sensor Performance,” Ali Hashemi, hardware/firmware engineer, FUTEK, will explore the challenges that affect sensor performance and how FUTEK’s electric engineering R&D team is working to resolve them.

The series will also help mechanical and electrical engineers understand how to work together to solve engineering challenges. Said Navid Mokhberi: “These engineers are often working apart until integration, and if design teams aren’t on the same path during development, it could cause problems in the end.”

Join us February 23-25 for the free 3-day online course, “For Good Measure – How Advanced Sensor & Electronics Solutions Are Shaping Medtech Innovation.”

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)