Outsourcing in Device Industry Not Big, But Getting There

Outsourcing in the medical device industry does not match that of other industries such as automotive or electronics.

February 25, 2011

|

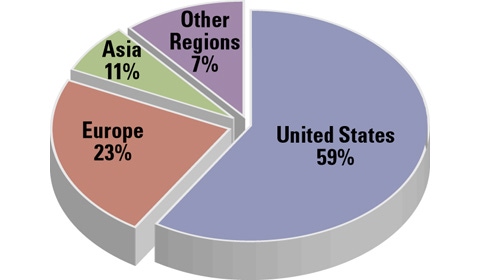

A regional breakout of the forecasted outsourcing market from 2010 to 2015. |

Outsourcing in the medical device industry does not match that of other industries such as automotive or electronics. In the early 1990s, about 7% of medical device manufacturing was outsourced. Although this number has grown, the figure is still less than 50%, which means there’s significant room for growth, especially within the next five to 10 years, according to a recent report, "New Taxes Could Encourage Medical Device Outsourcing" by Kalorama Information.

The global medical device outsourcing market is currently driven by several issues faced by manufacturers, according to Bruce Carlson and Daniel Granderson, authors of Kalorama’s report, “Contract Manufacturing in Medical Devices.” Device manufacturers are feeling pressure to streamline operations to achieve more cost effective processes, and the global market wants to see more product innovation as well as larger product volumes. In addition to meeting market demand, manufacturers are feeling the heat from group purchasing organizations to overcome pricing pressures. As a result, more stress is placed on company staff and facilities.

According to the online business journal Knowledge@Wharton, 97% of device manufacturers said in 2008 that outsourcing was good for their business. However, 72% of those manufacturers have never outsourced product development. With the recent economic changes and increased cost pressures, the number of device manufacturers that opt to outsource is expected to rise.

As more manufacturers choose to outsource, they should make sure that they have adequate quality controls in place in their manufacturing processes. They should also establish IT systems that enable product tracking and tracing. Implementing effective supply chain management processes will help companies accelerate time to market in both established and new markets.

|

|

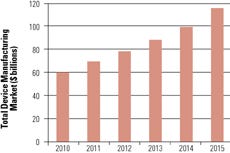

The global outsourcing market will continue to grow due to the aging population as well as a need on the part of device manufacturers to show savings. Due to an overlap in market segments, the three categories do not add up to the total revenues. |

Big Trends in Contract Manufacturing |

|

Why are Manufacturers Outsourcing? |

|

All data sourced from Kalorama Information’s report, “Contract Manufacturing in Medical Devices.” For more information, visit www.kaloramainformation.com.

About the Author(s)

You May Also Like

.jpg?width=700&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)