Baxa Corp.: Greatness Thrust Upon Them

June 1, 2007

OUTSTANDING QUALITY AND REGULATORY TEAMS

|

Many device companies need a wake-up call when it comes to quality. What makes a difference is how a firm responds when it receives that call.

In October 2000, Baxa Corp., which makes products for handling, packaging, and administering of fluid medications, received a warning letter. The letter highlighted FDA-483 issues, including problems with validation and recordkeeping. The Englewood, CO–based company's response to that letter was to completely overhaul its quality and manufacturing systems. “Up to that point, quality was a function of only one department in the company. It wasn't cultural,” says Patrick Hynes, vice president of global quality.

For 12 months, Baxa concentrated on improving the system, and during that time it voluntarily did not produce any new products. “We felt that [the quality system] was important enough to stop R&D efforts. We even published this strategy in our annual strategic plan,” says Hynes. The strategy included making quality a task that happened at every stage of the manufacturing process.

Besides not being able to make a profit for an entire year, Baxa also lost a few employees. “We were changing the company culture,” says Marian Robinson, vice president of marketing. “It's natural that some people wouldn't be able to move with us.” But, she says, they didn't lose many. “Most people were adaptable and were just as committed to improvement as top management.”

Actually, both Robinson and Hynes give recognition to top management for its dedication. “Having top management on board had a huge effect. It takes leadership to accomplish these types of goals,” says Robinson. Hynes recalls the intense companywide meeting that followed receipt of the warning letter. “Our CEO, Greg Baldwin, sent the message loud and clear that this was our top priority.”

During the focus on quality, Baxa not only repaired its quality system, it also adopted lean manufacturing techniques. “The systems really go hand in hand,” says Hynes. For example, GMPs and lean both use visual controls (signs, labels, and color-coded markings that are immediately identifiable), and problems are accentuated rather than hidden. “It's only when problems are out in the open that they can be fixed.”

|

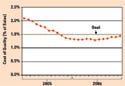

Figure 1. (click to enlarge) |

Part of the firm's strategy, besides increasing visual controls, was to reduce batch sizes and to increase lot changeover. “If you are changing lots only every 4–6 weeks, you will soon have a quality nightmare,” Hynes says. In addition, Baxa adopted statistical methods to track processes (see Figure 1).

The company uses a set of principles to maintain quality that are centered on providing statistical validity, keeping information visible, and using standard measurements. It also keeps finished goods separate from raw materials on the manufacturing floor. In fact, before Baxa moved to its new facility, it had to rent a 10,000-sq-ft warehouse to hold finished goods. “It was a bit of a nightmare, but it gave us the freedom we needed to revise the system.” Eventually the company was able to acquire a new building that was purpose-built to maintain quality.

Hynes explains that Baxa's quality system will never be finished. “There is no continuous improvement in the absence of standards,” he says. And the company's goal is to continually reassess and enhance its processes.

One way to do so, he says, is to monitor all FDA warning letters that are published. He says this helps him understand the types of problems other companies are facing so that he can prevent such occurrences at Baxa.

“FDA is an advocate for the consumer, and so are we. But we don't do this for FDA's benefit, we do it for ourselves,” says Hynes. Nonetheless, he credits FDA inspector Nick Nance for providing his expertise. “FDA helped this company go to the next level.”

By October 2001, Baxa had its new system in place and had hosted a successful follow-up inspection. Then, Robinson says, people started to see the improvements, some of which were unexpected. “The system helped us be more efficient, which was counterintuitive. You are doing all these extra steps, but there is less to do later.”

|

(click to enlarge) |

In fact, Robinson credits the success of the company with the combined lean and quality systems. “The business took off right about the time we finished putting the system in place.” She explains that just a few months later, a competitor had a widespread recall of its products. Baxa was able to step in with replacement products for those customers. “There is no way we could have responded to such a large-scale need if we had not turned this company around,” she says. “It took us from having 30% of the market to being the market leader.”

Although it took a warning letter for Baxa Corp. to rethink its business practices, it's clear that the company has taken the warning to heart. And in the process, the firm was able to increase its potential to serve customers.

The Baxa Team

Steve Beauchamp, quality engineer

Deneen Bueno, quality control technician

Kim Dinh, quality control technician

James Dozler, quality control technician

Cheryl Eastep, document control supervisor

Brent Halvorson, software quality engineer

Holly Higman, quality engineer

Gary Holland, quality engineer

Leneatra Hughes, document control

Patrick Hynes, vice president, quality

Tatiana Kannady, software quality engineer

Michael Kim, quality engineering manager

Junko Kojima, quality control technician

Prasong Manhkhong, quality control manager

DeAnna Pare, document control

Monique Phadavone, quality control technician

Sarah Read, quality specialist

Jenny Simpson, quality control lead

Ron Sliter, quality control technician

Frances Snell, quality control lead

Anne Szilagyi, quality specialist

Kasey Taylor, quality control technician

Doug Warren, software quality engineer

Gloria Wheelersburg, quality control technician

Kimberly Zizik, regulatory assurance supervisor

More Teams

Copyright ©2007 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like