Surgical Instruments: Converting from Metal to Plastic

MOLDING

October 1, 2006

Many companies find it difficult to reduce the cost of metal surgical instruments. The production, cleaning, and sterilization of metal components can be expensive, and there is little that can be squeezed out of the equation. An alternative is to shift from metal to plastic, which can be injection molded. Injection-molded plastic offers several advantages over metal components. Not only can components be made at a lower cost, but, for disposable ones, switching to plastic can even reduce sterilization requirements.

Plastic components are lightweight and can also be color-coded, making packaging more efficient. But companies need to be able to overcome the challenges—including material selection, part tolerances, design, and tooling—that can arise when engineering plastics into surgical instruments.

Reusable versus Disposable

|

Table I. (click to enlarge) Steam-autoclavable materials for medical instruments. |

The first step is deciding whether to design instruments to be reusable or whether to make them disposable. The material requirements for each are quite different. Reusable instruments are most likely going to be steam sterilized. For this type of application, manufacturers should select plastic resins that can be autoclaved. It's important to note, however, that autoclavable resins are much more expensive than those that can be used for disposables. Instruments also need to be strong and impact resistant, which further limits the selection of resins. Some resins may be used to form handles, however. Handles can benefit from soft-touch materials like thermoplastic elastomers (TPEs) or thermoplastic olefins (TPOs). Table I lists examples of autoclavable materials that are commonly used for instruments and handles.

|

Table II. (click to enlarge) Gamma-sterilizable materials for medical instruments. |

Disposable components have less-restrictive resin requirements and are less expensive. After molding, disposable instruments are usually ultrasonically cleaned, blister packaged, and gamma irradiated. Strong, impact-resistant resins commonly used in surgical instruments are listed in Table II.

One advantage of these resins is transparency, which allows a surgeon to see through the instruments during surgery. But transparent or translucent resins may experience a color shift during the gamma sterilization process, so it's important to work with the material supplier to achieve the desired results. Another advantage is color coding, which can be useful with series of parts that are different sizes or that are used with other components. Color coding allows a surgeon or other operating-room personnel to quickly identify the appropriate equipment.

Part Tolerance Requirements

Part tolerance requirements (first-article inspection) can be one of the most difficult challenges a team faces with plastic instruments, especially for companies that have little or no experience with the tolerances of plastic components. Companies that are used to making metal components are familiar with the repeated machining, multiple setups, and the different methods required for them. But the tolerance requirements for metal instruments are completely different from those for plastic molded components. The device must be properly designed in order to have proper function in spite of these variations.

Each organization must develop a method for approving the dimensional differences to determine what will be an acceptable molded product. Injection-molded-plastic suppliers should be able to provide realistic expectations for part print generation, first-article reports, and capability studies.

Because metal parts are machined, there is typically a dimension for every piece of geometry with tolerances that are suitable for drilling, milling, grinding, etc. For example, a 0.250-in.-diam drilled and bored hole would have a tolerance of +0.006/–0.000 in. This tolerance works well for a machinist, but in molding, all geometry should be in the middle of the tolerance. If this were a 0.250-in. diameter hole in a plastic part, the tolerance would look more like ±0.003 in. The amount of tolerance remains the same, but the hole can stay within the tolerance range as the plastic process varies throughout the production run. It is extremely important for engineers designing a 3-D database to make sure all the geometry resides in the center of the feature's tolerance zone.

As for part prints, make three separate sets to move parts through the approval process quickly and easily.

The first set is a completely dimensioned print (just like metal prints), including every geometry feature dimensioned. The quality department, which is familiar with metal-part first articles, will need this set to approve the parts. The features should only have to be measured once to verify whether the mold is producing the parts according to specification. The process needs to be verified with a design of experiments (DOE), which is explained in more detail below.

The second set contains only the critical geometry dimensions—the geometry features that interact with other components vital to the function of the part. These dimensions will be checked each time the part is molded to verify that the part will function correctly.

The third set of prints contains only a few dimensions—only those features affected most by the molding process, such as hard-to-fill thin areas, overall width and height, and the weight range of the parts. This print is for in-process checks at the molder.

Design of Experiments

A DOE needs to be run on the molding process to determine the limits of process variations (the process window) allowable within the tolerance zone. This DOE uses different parameters of the molding process, which could include resin melt temperature, mold temperature, injection pressure, injection speed, injection profile, injection time, and cooling time. It is important to include all those parameters that are necessary to prove that the process is acceptable.

Once the DOE is finished, a first article can be completed on the molded parts to determine which molding process will yield the best in-tolerance part. Molded parts will have uniform dimensions for the rest of the tool's life, provided that the tool isn't damaged. Parts will vary, however, within the process parameters established in the DOE, so in-process checks must be used. In-process checks consist of measuring the critical dimensions of the part throughout the molding production run, typically once per hour.

Plastic Part Geometry: Strength and Moldability

The strength properties of metal are generally superior to those of plastic, so it's important to determine whether a plastic resin is available that meets the requirements of the instrument's intended use. If the instrument is going to be pried with a long lever arm or impacted by a hammer, plastic may not be optimal. But if the tool is simply a cutting guide or a static spacer, then plastic may be suitable.

Filled plastic materials provide much more flexural strength than unfilled resisns. Their strength can be close to the strength of some metals. Certain resins can also be molded in thick sections. For example, a polycarbonate can be straight injection molded up to approximately 0.180-in. wall sections. Glass-filled nylon can be molded up to a 0.375-in. wall thickness. Certain additives, such as structural foam, can also yield thicker parts. These additives can be combined with many different types of plastic resins and are able to withstand sterilization after molding. The structural foam additive can improve impact strength when used with certain types of resins and can keep the part from sinking or warping.

|

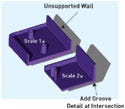

Figure 1. (click to enlarge) An unsupported wall that must remain perpendicular can be created by adding a groove at the intersection of the perpendicular and main walls. |

Plastic parts have a tendency to warp and sink in certain areas, and so they must be designed to overcome these tendencies. One difficult piece to produce in a part is an unsupported wall that remains perpendicular. If this wall can't be designed with a supporting rib, a feature can be added that removes the thick area created at the intersection of the perpendicular and main walls (see Figure 1). A thick area stays hotter longer, which increases shrinkage in the part and pulls the wall inward.

|

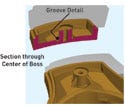

Figure 2. (click to enlarge) To avoid sink around a thick boss, a groove can be inserted through the center of the boss. |

Another potential problem is sink around thick bosses. For example, a large-diameter boss with thick walls for threaded inserts or screw holes for self-tapping screws usually becomes too thick and tends to sink. Use the same type of feature described above for the wall intersection. The feature will be made around the boss at its intersection to the main wall (see Figure 2). Another option is to use structural foam, which can reduce sink in thick parts and can reduce molded-in stress, which causes warpage.

For an example of a metal-to-plastic instrument application see Figure 3, an ankle clamp designed by John Grecco of Stryker Orthopaedics. The clamp is used in knee replacement surgery. The yoke and flippers were previously made of stainless steel, and the instrument assembly needed to sustain multiple steam autoclaves. The designer determined that the strength of a polysulfone resin would be sufficient to meet the instrument's requirements. In addition, the high-heat properties of polysulfone would allow it to withstand the temperatures of steam autoclaving. In its new, plastic design, the yoke attaches to a metal component that interacts with the rest of the instrument. The flippers are simply a pair of molded parts, but require a nice press fit over the pivot bushings. A torsion spring interacts with these two flippers.

|

Figure 3. This ankle clamp designed by John Grecco of Stryker Orthopaedics attaches the plastic yoke to a metal component that interacts with the rest of the instrument. |

Overmolding Metal with Plastic

It is possible to reduce costs in instruments by simplifying the metal-machined component with a plastic overmold in areas that do not need to be metal. In some cases, a part has complex geometry to fit the contours of the human body but only has one area that connects to a metal handle. For these situations, the entire complex machining process can be eliminated by molding a plastic part and making the connection with a metal insert. Or perhaps the component must attach to another instrument using magnetism; simply overmold or insert a magnet into the molded part to achieve this requirement.

The plastic part needs to seal off on some of the metal insert surfaces to hold it in place while molding. The injection pressure of the plastic resin entering the cavity is typically quite high and will move a metal component around it if it is not retained securely. Sealing off the metal insert surfaces can be a challenge for the toolmaker, since the surfaces need to be held to a very small tolerance. This tolerance would be ±0.002 in. for typical resins and ±0.0005 in. for TPE-type resins. Springs in the injection mold can sometimes increase the seal-off tolerance by making the seal-off area an insert. For example, if a metal component has a ±0.0005-in. tolerance in the seal-off area, a toll insert with springs that is built to the shape of the metal component can increase that tolerance to ±0.001 in. The insert is allowed to move inside the tool and is supported with a strong spring that will withstand injection pressure while molding. Be sure it will be able to adjust to the amount of tolerance in the inserted machined-metal component. Plan to replace this insert easily, since it will be a high-wear item.

Handles can be overmolded in an ergonomic shape that fits the surgeon's hand but that can still interact with attachments or be hit with a mallet. A simple shaft of metal can be overmolded with a plastic resin to form the ergonomic shape. Handles can be made with a soft-touch grip, resulting in a double-shot overmolded handle.

The end shut-off geometry on this type of handle is critical because of TPE-like materials' tendency to flash into, or over, gaps that are 0.0005 in. Machine the shut-off area to ±0.0005 in. or better, and consider the spring features discussed as a necessity.

If the handle is a reusable item that needs to be sterilized, create a part that has extremely small, or no, gaps that might trap contaminants from the surgical procedure. Work with the metal supplier and molding vendor to determine a feature in the metal that will hold the TPE resin in place so that it can't pull away and leave a gap.

Prototyping

Account for extra prototyping time and the additional associated costs. It's very important to make sure that parts fit up to mating components. This can be done using any of the plastic prototype methods, such as stereolithography or selective laser sintering. If the part or tool has snap features, consider 3-D ABS-type printers so it can be made from amorphous-like resins. There are now prototype materials that are soft and flexible like TPEs or TPOs.

Next, build a simple tool in a single-cavity configuration so that the intended plastic resin can be molded. The tool can be made in an epoxy tool process for just a few parts, or it can be made out of steel or aluminum. If there are undercuts that would be made with cam slides or angled lifters, make these features with hand-loaded cores or use secondary operations such as milling or drilling.

Conclusion

Reducing the cost of metal surgical instruments may require switching to plastic. Compared with metal, injection-molded plastic offers several advantages, including lower cost and reduced sterilization requirements. However, manufacturers that are looking to plastic as an alternative must carefully consider material selection, part tolerances, design, and tooling.

The molding vendor will play a vital role in developing plastic instruments. Another important member of the team will be the mold maker. The molder may have in-house mold building or may use a stable of outside tooling vendors. Either way, the molder is ultimately responsible for ensuring the mold can produce a part that meets all specifications. Manufacturers that address these challenges can often make a smooth transition from metal to plastic instruments.

Randy Pell is senior staff engineer for Mack Molding Co. (Arlington, VT). He can be contacted at [email protected].

Copyright ©2006 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like