Peptide-Based Inks for 3D Printing May Boost Regenerative Medicine

Hydrogel could be used for 3D printing structures that can grow active cells for transplant within living beings.

March 30, 2023

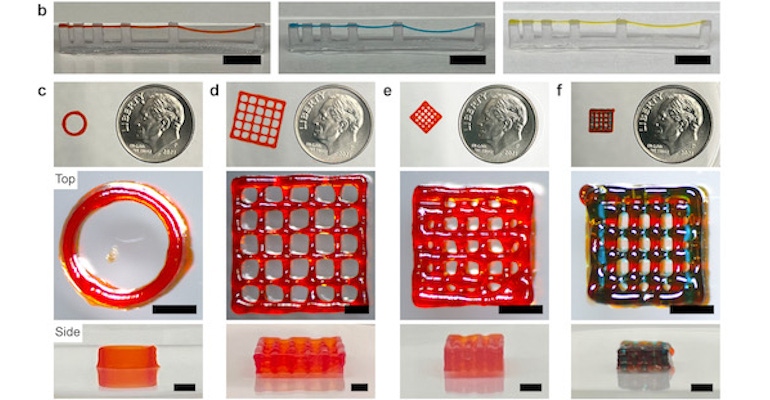

Researchers have developed new inks that can be used to print cell-based structures that can eventually become new human tissue, representing a step forward for using 3D printing for regenerative medicine, they said.

A team in the lab of Jeffrey Hartgerink, principal investigator for Rice University's Department of Chemistry & Department of Bioengineering, developed a self-assembling peptide that they use as a base for 3D-printing inks, they said. Peptides are chains of amino acids that are comprised of less than 50; when these are longer than 50 amino acids, they are called proteins.

"In this work, we used peptides as our base material in our 3D-printing inks," said Adam Farsheed, a Rice bioengineering graduate student in Hartgerink's lab who worked on the project.

The peptides developed by the team are called “multidomain peptides," which are designed to be hydrophobic on one side and hydrophilic on the other. When they are placed in water, “one of the molecules will flip itself on top of another, creating what we call a hydrophobic sandwich,” Farsheed said.

It's a group of these sandwiches stacked on top of each other that form long fibers that then turn into a hydrogel, a water-based material with the consistency of gelatin that's often used in tissue engineering and other applications that require soft materials, researchers said. These also can include soft robotics and wastewater treatment, they said.

“Eventually, the goal is to print structures with cells and grow mature tissue in a petri dish," Farsheed explained. "These tissues can then be transplanted to treat injuries, or used to learn about how an illness works and to test drug candidates."

Softness as a Strength for 3D Printing

Researchers already knew of the usefulness of multidomain peptides for nerve regeneration, cancer treatment, and wound healing, as they can safely be implanted into the body with medical benefits. They also have demonstrated an ability to promote high levels of cell infiltration and tissue development when implanted in living things.

The question for the Rice University team was whether a peptide-based material as soft as the one researchers created could be used reliably in 3D-printing applications, Farsheed said. The answer for him was in the capability that multidomain peptides have to self-assemble, he said. “Our material can reassemble after being deformed, similar to how toothpaste forms a nice fiber when pushed out of a tube," he said.

Researchers published a paper on the results of their research in the journal Advanced Materials.

Farsheed himself has a background in mechanical engineering rather than materials science; thus, when he tested how the material would work in printing, he said he took "more of a brute-force engineering approach . . . instead of chemically modifying the material." This manifested itself in testing to see what would happen if he added more material, increasing the concentration about fourfold, Farsheed said. It ended up working "extremely well," he said, resulting in the ability to successfully print complex 3D structures using the material, he said.

When printing structures with the material, researchers used either positively charged or negatively charged multidomain peptides, they said. They found that immature muscle cells placed on the structures behaved differently depending on the charge, with cells remaining balled up on the substrate with a negative charge, while positively charged material causes cells to spread out and begin to mature.

This demonstrates how in the future researchers can control the behavior of cells printed using the material by using "both structural and chemical complexity,” paving the way for future exploration of its use in regenerative medical applications, Farsheed said.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)