How 3-D Printing Is Solving a Stent Problem

December 11, 2014

Stents that keep patients' airways open haven't changed much in the past 20 years, according to George Cheng, MD, a pulmonary and critical care fellow at Beth Israel Deaconess Medical Center in Boston.

Traditional tracheal stents are made of metal, silicone, or a combination of the two. They can move around within the trachea or lodge in the mucous membranes, creating a benign tumor, according to Cheng's mentor and research advisor, Adnan Majid, MD, director of the fellowship in interventional pulmonology and an assistant professor of medicine at Harvard Medical School. The tumor can block the stent, causing shortness of breath, retention of secretions, and possibly infection, Majid said.

Cheng first proposed designing an anatomically correct, 3-D tracheal stent made of medical-grade silicone, but learned that silicone is not 3-D printable. So he decided to make a 3-D digital model of the airway from a photonegative and inject that model with silicone. (Such "3-D injection molding" technology, pioneered elsewhere at companies including Stratasys and Worrell Design, has shown promise when it comes to combining the best aspects of 3-D printing and injection molding.)

|

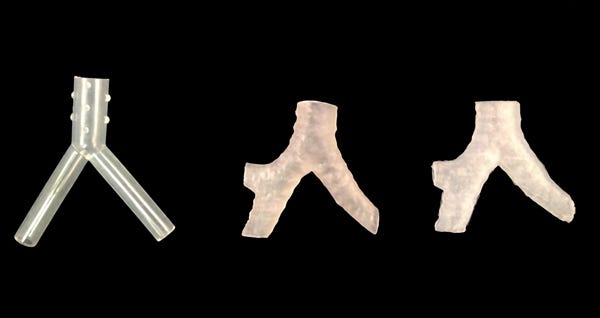

This image, provided by George Cheng, MD, shows the current Y stent available (left), a 3-D printed Y-stent based on patient anatomy (center), and a 3-D molded silicone stent (right). |

Cheng won a $50,000 grant from the Boston-based Center for Integration of Medicine and Innovative Technology to fund the research. The Boston Biomedical Innovation Center, which focuses on technologies aimed at improving patient care in heart, lung, blood, and sleep disorders, is providing expert opinions, market analysis, and other support to help Cheng's research move forward.

Of all the industries clamoring for innovation from 3-D technology, the life sciences could arguably benefit the most. 3-D printing could be used to do everything from print organs on demand to create custom exoskeletons and precise medical models for engineers. Researchers at the University of Rochester (NY) are even using 3-D printing to model aortic aneurysms, bulges in the aorta that often lead to death.

Majid believes that the patients who would benefit most from custom 3-D tracheal stents suffer from one of three conditions:

Tracheobronchomalacia, in which flaccid tracheal cartilage leads to tracheal, and ultimately, bronchial, collapse.

Tracheal stenosis or narrowing, caused by birth defect or injury.

Malignant tracheal obstructions caused by advanced cancer.

Cheng and Majid are using FDA-approved silicone in their research, in hopes of winning a quick approval from the government. They are also in talks with medical device manufacturers interested in making and marketing the stents.

The physicians declined to identify the companies, but Cheng said one is "very interested in adapting the 3-D printing to their current manufacturing process.

"As clinicians, our foremost priority is to do patient good," he continued. "We're not really interested in manufacturing, per se, but we think that pushing the boundaries and helping interested companies to develop this technique will potentially be a win-win for everybody."

Refresh your medical device industry knowledge at MD&M West, in Anaheim, CA, February 10-12, 2015. |

Nancy Crotti is a contributor to Qmed and MPMN.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like