3D-Printed Robotic Skin Is Ready for Multiple Applications

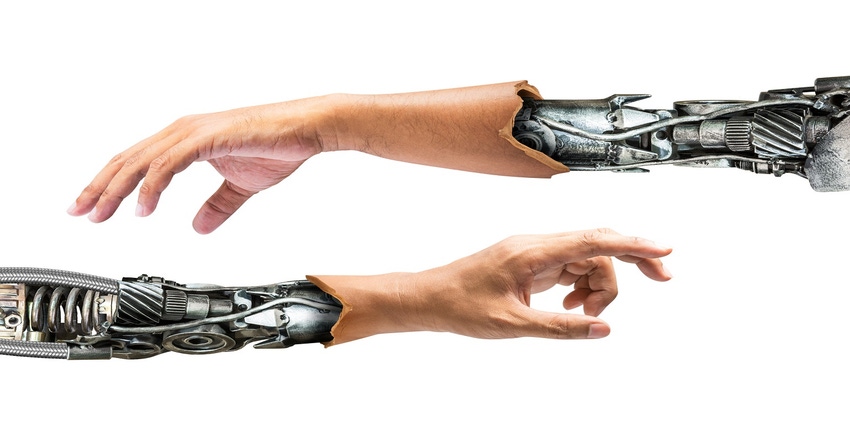

B9Creations and researchers have created robot skin with abilities beyond human skin.

September 13, 2023

Human skin is soft, flexible, and embedded with millions of sensor nerves. Scientists have been trying to replicate human skin for decades. B9Creations may have taken us a step further on the journey to create artificial skin.

The robot skin developed by B9Creations was designed to provide abilities beyond those of human skin. The goal is to improve prosthetics, healthcare, and even gaming. The robot skin has human-like sensing designed to advance human-machine interfaces, artificial intelligence, and wearables.

Researchers used 3D printing technology to create an adaptive robotic skin that possesses high sensitivity and wide bandwidth, as well as an enhanced pressure-sensing capability.

Compared to human skin, the thin-film pressure sensors on the artificial skin can sense pressure that is 97% lower than the minimum detectable pressure and 262.5% higher than the maximum detectable pressure.

The Layers of Robotic Skin

The adaptive robotic skin includes a microfluidic thermal actuator, an elastomeric enclosure, and an array of thin-film pressure sensors that have high uniformity between devices, as well as a wide range of sensitivity and bandwidth. The microfluidic thermal actuator was constructed by bonding two layers, one with a fluidic channel and another with a flat surface. The mold for the fluidic layer was created using a B9 Core Series 3D printer to achieve the desired channel pattern.

In the past, several studies have been conducted on robotic skin to replicate the flexibility, stretchability, and self-healing abilities of human skin, while also incorporating tactile sensing abilities to detect stimuli such as pressure and temperature. Even though cutting-edge technologies have nearly attained many of the properties and capabilities of human skin, the ability to sense pressure, which is considered one of the primary functions of the skin, still falls short of achieving actual skin-like performance – capable of either high-sensitivity or wide bandwidth, but not both simultaneously. The skin created by b(Creations was designed to address the issue of pressure.

Real-World Applications

According to B9Creatiohs, the potential of robotic skin extends well beyond its initial creation. Additional applications include:

Prosthetics:

Adaptive robotic skin can be used to create more sensitive and flexible prosthetic limbs, enabling the sensing of pressure, temperature, and other physical sensations, improving the user’s experience and control.

Robotics & Automation

The sensitive and flexible nature of robotic skin can be applied to robotic grippers and manipulators, enabling the handling of delicate objects and working more safely around humans. It can be used in industrial robots to help them navigate their environment more effectively and safely, as well as to detect damage, allowing humans to perform maintenance and critical repairs.

Wearable Technology:

Robotic skin can be used to create wearable devices that can monitor a person's vital signs, such as heart rate and breathing, in real time.

Healthcare:

Robotic skin can be used in several healthcare applications, such as pressure mapping for bedridden patients to prevent bedsores and detecting pressure points in wheelchairs. It can also be used to monitor the health of elderly patients or those with chronic illnesses, allowing for early detection and intervention.

Virtual Reality and Gaming:

Robotic skin could be used in virtual reality or gaming to provide more realistic haptic feedback and increase immersion.

Human-Machine Interfaces

Adaptive robotic skin can be integrated with human-machine interfaces to create a seamless connection between humans and machines.

Environmental Monitoring

Robotic skin can be used to monitor environmental conditions, such as temperature, humidity, and air quality, in real-time, providing valuable data for scientific research and environmental management.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)