Interface Catheter Solutions Offers Upgraded Balloon Inspection System

A provider of outsourced solutions for balloon and catheter manufacturing for the medical industry has upgrade its automated visual/dimensional balloon inspection system product to significantly reduce cycle times. Results of Gage R&R (repeatability and reproducibility) analysis show that the system is accurate, consistent and reliable for balloon inspection processes.

August 11, 2012

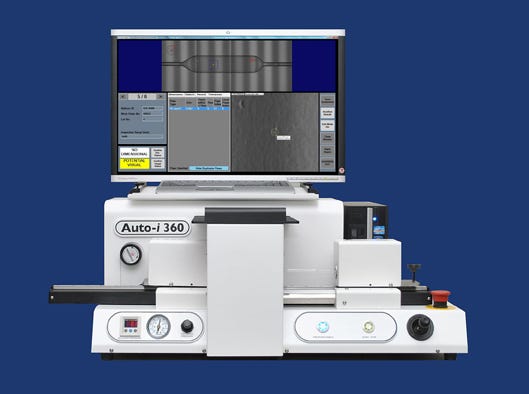

A provider of outsourced solutions for balloon and catheter manufacturing for the medical industry has upgrade its automated visual/dimensional balloon inspection system product to significantly reduce cycle times. Results of Gage R&R (repeatability and reproducibility) analysis show that the system is accurate, consistent and reliable for balloon inspection processes. The Auto-i 360 significantly reduces inspector-to-inspector balloon inspection variability and is the only system that provides both visual/flaw and dimensional measurements of medical balloons in a single operation. Gage R&R data shows significant increases in consistency, accountability, and quality in the inspection process. Inspection includes classification and size of defects with pass/fail analysis based on user-selected criteria. The balloon inspection system operates with a sophisticated vision system and analysis program with an intuitive user interface. The Interface inspection system provides immediate detailed visual and data reporting used in both quality manufacturing inspection and research and development.

A provider of outsourced solutions for balloon and catheter manufacturing for the medical industry has upgrade its automated visual/dimensional balloon inspection system product to significantly reduce cycle times. Results of Gage R&R (repeatability and reproducibility) analysis show that the system is accurate, consistent and reliable for balloon inspection processes. The Auto-i 360 significantly reduces inspector-to-inspector balloon inspection variability and is the only system that provides both visual/flaw and dimensional measurements of medical balloons in a single operation. Gage R&R data shows significant increases in consistency, accountability, and quality in the inspection process. Inspection includes classification and size of defects with pass/fail analysis based on user-selected criteria. The balloon inspection system operates with a sophisticated vision system and analysis program with an intuitive user interface. The Interface inspection system provides immediate detailed visual and data reporting used in both quality manufacturing inspection and research and development.

Laguna Nigel, CA

You May Also Like