Moth Eyes Inspire Low-Dose X-Ray Imaging

July 11, 2012

|

Scanning electron microscope image shows the eye of a leaf miner moth. (Image courtesy of Dartmouth College) |

X-rays are among medicine's most remarkable achievements, enabling doctors to see inside the body without having to wield a scalpel, remarks FDA in a statement to consumers. However, along with their tremendous value, medical x-rays expose people to radiation, which can increase their chance of developing cancer later in life. In addition, at very high levels, radiation can result in cataracts and skin burns. Operating on the principle that necessity is the mother of invention Yasha Yi, a professor in the integrated nanophotonics laboratory at City University of New York, hopes to increase the powers of x-ray technology while minimizing patients' exposure to dangerous radiation.

Inspired by the antireflective properties of the moth's compound eye, Yi and his colleagues are developing an antireflective nanostructured scintillator material that can improve the light-capturing efficiency of x-ray equipment and other medical imaging devices. When struck by incoming x-ray photons, such scintillators absorb the energy of these particles and then reemit the absorbed energy in the form of visible light. In imaging applications, such scintillators convert the x-rays exiting the body into visible-light signals that are captured by a detector and converted into images.

Measuring 500 nm in thickness, Yi's scintillating material consists of crystals known as cerium-doped lutetium oxyorthosilicate. These crystals, in turn, are encrusted with tiny silicon nitride bumps that are modeled after the structures in a moth's eye.

In the following Q&A, Yi explains how the eye of the lowly moth is serving as a model for improving patient safety and advancing the practice of medicine. --Bob Michaels

|

|

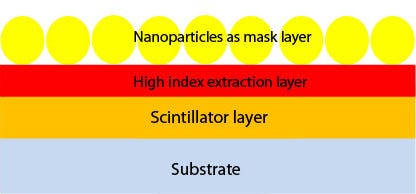

The illustration above shows the self-assembly of SiO2 nanoparticles on the top of a high-index light-extraction layer, which is deposited on a Lu2SiO5:Ce thin film. The SEM image below shows the improved bioinspired nanostructures. (Images courtesy of Optics Letters) |

MPMN: How does the moth eye improve light-capturing efficiency, and how is this capability inspiring your work to develop new x-ray and other medical imaging technologies?

Yi: The most important part of a medical imaging device is the scintillator material. In conventional medial imaging devices employing a scintillator material, the function of that material is basically to convert the x-ray to visible light. The bottleneck in using this material is that when you convert much of the light from the x-ray to photons, or visible light, those photons cannot escape from the scintillator material. Thus, most of the light is trapped inside the emission, or scintillator, material.

To overcome this bottleneck, we have been inspired by nature--the moth eye, in particular. If you study the moth eye, you see that it is very sensitive even under dark conditions. It can sense very weak light, and it has this capacity because of its excellent antireflection properties. My team utilized the idea of the moth eye to be able to extract more light from scintillator material. We borrowed the intrinsic optical characteristics of the moth eye and implemented it in developing a scintillator material for medical imaging techniques that can extract more light from x-rays. Now, we are able to gain more visible light using the same x-ray dosage level, or we can achieve the same amount of visible light using a lower x-ray dose.

MPMN: But why was the moth eye in particular a suitable model for your work? Why not the eye of another type of insect?

Yi: We had been studying the moth eye for quite some time for another project in which we sought to develop a very low reflection layer. In the course of that project, we hit on the idea that we could apply the nanostructure of the moth eye to the scintillator material used in medical imaging devices. That's the immediate reason we used the moth eye, but nature has provided us with many, many interesting structures that could serve as models for our work. While the moth eye has been our model, other structures could possibly help to improve the efficiency of the scintillator material. Thus, the moth eye is merely a typical example of how we rely on natural biostructures to derive more light from scintillator material.

MPMN: Could you describe the material?

Yi: The scintillator material can convert short-wave light to a longer-wave light. A thin film, this material is really a series of materials; it has many types of compounds and elements. In medical imaging devices, this film is just one of many components. It is deposited inside the imaging equipment, which also includes the x-ray source, detectors, mechanical parts, and many other complicated components.

MPMN: In its present state, how effective is your nanostructured scintillating material at increasing visible-light output?

Yi: Our technology is in its very early stages. At this point, we have demonstrated a proof of concept that enables us to show that the technology works. Eventually, we would like to work with a medical imaging device company or with a company that provides scintillator material for imaging equipment so that we can test our ideas using real devices. This would provide us with an opportunity to perform extensive efficiency studies. However, cost is a potential issue. You don't want to add much more cost to equipment that is expensive to start with. Thus, we face serious challenges, and there is a long way to go from the lab to the x-ray room.

MPMN: In your proof of concept, are you able to quantify the efficiency of your technology in increasing visible-light output without raising the x-ray level?

Yi: At this time, standard scintillator materials used in imaging applications have very low efficiency. To improve the material's efficiency, we put a mothlike nanostructure on top of an existing scintillator to extract more light from this material. In our work, we have demonstrated that by using our thin film, the output of visible light can be enhanced by 175% at the standard x-ray dose. Thus, to achieve today's standard visible-light output, the x-ray dose can perhaps be halved. These numbers are pretty significant, indicating the utility of applying our technology to practical medical imaging devices.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)