Critical Insight: Marking Devices with Radiopaque Coatings

May 1, 1999

Medical Device & Diagnostic Industry Magazine

MDDI Article Index

An MD&DI May 1999 Column

Meet the author! |

New technologies for applying radiopaque coatings enable products such as stents, catheters, and guidewires to be easily seen on x-rays and fluoroscopes during critical interventional procedures.

Vascular catheters and guidewires are widely used in procedures ranging from the diagnostic evaluation of stenosis to balloon angioplasty and the deployment of stents in coronary arteries. The process of inserting a catheter in a vein or artery requires that the practitioner know the exact location and orientation of the catheter's distal tip at all times. For percutaneous transluminal coronary angioplasty (PCTA), the deflated balloon catheter must be positioned accurately in the artery before it is expanded to compress the obstruction. The placement of stents in the coronary vasculature is a similarly critical procedure, and the surgeon or interventional cardiologist must be able to follow the movement of the stent through the patient's artery to precisely position the device at the affected site.

However, determining the position of guidewires, catheters, or stents on a fluoroscope or x-ray film can be difficult, as the devices are not always easily seen. For improved visibility, practitioners can select stents and catheters that incorporate "markers." These markers—unlike the silicone or plastic of a catheter—block the transmission of x-rays. As a result, they appear as contrasting images against the background of the fluoroscope or x-ray film. The opacity, degree of contrast, and sharpness of the image varies with the material and type of process used to create the marker.

This article discusses traditional approaches for improving the visibility of vascular catheters and stents and compares these methods with the more advanced technology of radiopaque coatings.

CONSIDERATIONS FOR ACHIEVING IMPROVED VISIBILITY

While techniques vary for producing markers, all processes for improving device visibility on fluoroscopes and x-ray film are based on incorporating a material that absorbs the radiational energy of the x-rays (Figure 1). This material—typically a metal—is added to the device in the form of a layer, coating, band, or powder, depending on the nature of the process.

Figure 1. Interventional cardiology devices marked with radiopaque coatings (left) are easily visible under x-ray (right).

Figure 1. Interventional cardiology devices marked with radiopaque coatings (left) are easily visible under x-ray (right).

There are three primary considerations in applying a metal marker. First, the metal should not add significant stiffness to the device. A notable example is the guiding catheter (a catheter through which a balloon catheter is introduced), which needs to be pliable so it can bend and turn as it is maneuvered through the artery. Although the guiding catheter is almost invisible on fluoroscopes and x-ray film, device manufacturers have historically refrained from attempting to improve the device's visibility because of a concern that flexibility would be sacrificed. The technology of radiopaque coatings now makes the application of markers on such devices feasible.

Another important consideration is that the material being added to the device be biocompatible to negate the possibility of adverse reactions with the patient. Inert noble metals such as gold, platinum, iridium, palladium, and rhodium are well recognized for their biocompatibility. They are also impervious to oxidation and are among the densest metals known—an important characteristic in terms of opacity and the quality of the fluoroscopic or x-ray image.

Finally, the radiopaque metal must adhere without the possibility of peeling or delamination. Catheters, and especially stents, are severely flexed, and the bond between the metal and the device must be able to withstand the forces generated. Whether the device is indwelling or transcutaneous, poor coating adhesion can result in serious complications.

CONVENTIONAL TECHNOLOGIES

Metal Bands. An early method of marking catheters involved crimping or swaging metal bands at selected points so that the practitioner could see the location of the device. Catheters with bands of gold and other noble metals are still being marketed, but cardiologists generally prefer the newer methods of marking. Bands have the potential for coming loose and shifting or falling off. They have also been known to actually cause an abrasion to the intima during insertion of the catheter. Additionally, cellular debris can become trapped between the device and the band, and the edges of the band can serve as a site for thrombus formation.

Barium-Filled Catheters. Another means of achieving visibility is by loading the catheter material with a metal powder. A metallic element long employed in radiology, barium is most often used, although tungsten and other fillers are appearing on the market. A distinct disadvantage of these types of filled catheters is that the entire length of the device is opaque, which prevents viewing of the vein or artery wall behind the catheter. With unfilled catheters, the surgeon can see through the unmarked areas of the device, which is sometimes essential, as in assessing balloon effectiveness.

Other Methods. Metal coatings can also be applied as markers to catheters and stents using such methods as chemical vapor deposition (CVD), physical vapor deposition (PVD), and electroplating of gold. For CVD and conventional PVD, the uniformity and opacity of the radiopaque layer can be a concern, and the coatings do not adhere well enough to be reliable. Electroplated coatings are porous and can present a biocompatibility problem, since the plating solutions used for electroless and electroplated surfaces are incorporated in the coating and are generally not biocompatible.

TRADITIONAL ION-BEAM-ASSISTED DEPOSITION

According to Lloyd Klein, MD, director of interventional cardiology at the Rush Heart Institute in Chicago, "Radiopaque coatings are considered to be the current technology in the medical device industry and are rapidly gaining wider acceptance and use by cardiologists."

Radiopaque coatings can be applied to catheters and stents using a high-vacuum deposition process that results in dense thin-film coatings (typically less than 10 µm) that adhere well, even under limited flexure. Traditional ion-beam-assisted deposition (IBAD) employs PVD—that is, an electron-beam evaporator—to create a vapor of atoms that coats the surface of the device. The process differs from conventional PVD in that the film is bombarded with ions from an ion gun, with energies typically in the range of 1.0 to 1.5 keV. As a result, energy is transferred to the coating atoms, allowing them to migrate on the surface, and the coating can grow in a more uniform manner.

This process can be employed to apply radiopaque coatings in selected locations and patterns on the device. The coating materials usually consist of noble metals, including gold, platinum, iridium, palladium, and rhodium. For certain products, such as devices made of Teflon or polyurethane, interlayers of biocompatible chromium and titanium are sometimes used to optimize adhesion.

One of the problems with producing coatings by traditional IBAD is that the process is costly. Even though only a small amount of material ends up on the substrate, the expensive noble metals are ejected out over a large angle. Because an evaporator uses molten metal, it must be located upright on the floor of the deposition chamber so that the metal does not spill out, thereby restricting the size and configuration of the chamber.

In addition, evaporators cannot deposit alloys very effectively because of the varying vapor pressures of the different constituent materials. The composition of the resulting coating constantly changes as one material is removed from the crucible more rapidly than others.

Finally, with coating atoms traveling toward the target from one direction and an ion beam bombarding the substrate from a different direction, the energy transferred to the atoms will vary depending on the extent to which the atom and ion streams overlap. As a result, the film-growth mechanism is inconsistent, and uniform coating properties can be difficult to achieve, even over the same substrate.

For these three reasons—cost, physical limitations, and process limitations—traditional IBAD is only practical for small-volume applications.

ADVANCES IN RADIOPAQUE COATINGS

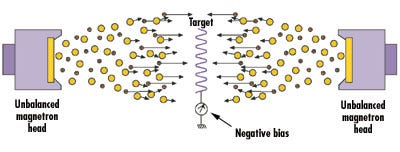

A recent development in radiopaque coating deposition has been designed to address some of the deficiencies of traditional IBAD, including the lack of uniformity in coating thickness. To achieve the desired uniformity, the technique—known as microfusion—eliminates a separate evaporator and ion gun and replaces them with a process based on magnetically coupled "unbalanced magnetron sputtering." As can be seen in Figure 2, two magnetrons are positioned opposite one another, with their magnetic fields coupled and unbalanced to the same degree. The substrate to be coated is placed between the magnetrons. Provision is made for an adjustable bias to be applied to the substrate, as required, to control ion energy and flux.

Figure 2. In the magnetically coupled unbalanced magnetron sputtering process, ions from the plasma (small circles) bombard the surface of the device being coated as metal atoms (large circles) simultaneously deposit.

In a typical magnetron, the magnetic field lines run between outer magnets, arranged in an annulus, through a sacrificial metal sputter target to a central inner magnet. In an unbalanced magnetron, not all of the field lines are captured by the central magnet. By controlling the negative-bias voltage on the substrate (or its fixturing for nonconducting materials), ions can be accelerated from the plasma toroid in front of the sputter head toward the target. At the same time, ions from the toroid also sputter atoms from the sacrificial metal, producing a flux of coating material. Both the metal atoms and the high-energy ions travel collinearly, hitting the same regions of the substrate at the same time and ensuring a highly dense and uniform coating. Areas where no coating is desired can be masked.

Figure 3. Microfused radiopaque coating being applied to guidewires.

Figure 3. Microfused radiopaque coating being applied to guidewires.

Unlike an evaporator system, the microfusion method permits multiple sources to be used and placed in any orientation (Figure 3). Multiple heads can be employed to coat parts on more than one side at a time without turning the piece, greatly reducing deposition times and enabling the process to be used for large-scale production. Uniform and consistent alloys, mixtures, and oxides can be deposited in two different ways. In the first, a coating having a specific composition or alloy can be laid down by using a sputter target of the same composition and alloy. After an initial "break-in" period, the ratio of the deposition rates of the constituent materials at the substrate comes to equilibrium at the compositional ratio of the target. Alternatively, two heads can be used in any relative combination to create a mixture or alloy. In fact, one material can be graded into another, creating a seamless multilayer coating (Figure 4).

Figure 4. Catheters marked with multilayer gold and platinum radiopaque coatings.

Figure 4. Catheters marked with multilayer gold and platinum radiopaque coatings.

Microfused radiopaque coatings using noble metals are more effective in stopping the entire spectrum of an x-ray source, yielding visibility superior to that of radiopaque coatings produced with the use of an evaporator. The critical factor is the bond strength or adhesion of the coating. The microfusion process also creates a compressive stress in the metal as it is applied, which increases the degree of bending and flexing the device can experience.

A final advantage of this type of coating process is the ability to apply discrete bands near the distal tip of a catheter to provide markers of precise lengths and widths. Such bands can be used as an in-situ "ruler" to more accurately determine the size of vascular lesions, potentially reducing any unnecessary use of multiple stents.

CONCLUSION

For certain catheters, guidewires, and stents, improved visibility under fluoroscopy is a highly important property to surgeons or cardiologists who must accurately determine device location and orientation. While a number of techniques are available for adding markers, radiopaque coatings can achieve better results than conventional methods, with less impact on the physical characteristics (size, weight, flexibility, etc.) or performance of the device. The recently developed technology of microfused radiopaque coatings offers the potential to overcome certain limitations of traditional radiopaque coating methods in terms of density, opacity, and uniformity.

Richard Sahagian is director of medical products for Implant Sciences Corp. (Wakefield, MA). The company provides surface treatments and thin-film coatings to the medical device industry, including microfused radiopaque coatings, nitrogen ion implantation and ceramic coatings for orthopedics, and implantation of radioisotopes for intravascular radiation and brachytherapy.

Copyright ©1999 Medical Device & Diagnostic Industry

You May Also Like