Rising 'STAR' in Biomaterials Benefits Implants

May 20, 2009

Originally Published MPMN May 2009

MD&M EAST 2009: FIRST-TIME EXHIBITORS

Rising 'STAR' in Biomaterials Benefits Implants

|

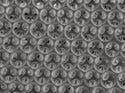

Healionics is the developer of STAR biomaterial, a 3-D scaffold that promotes biointegration. |

When applied to a material, the term biocompatible is generally accepted in the medical device industry as meaning that it will not elicit a strong immune response from the body and is essentially inert upon implantation. Some materials experts argue, however, that biocompatible implantable materials should not be inert, but rather should actually incite a reaction--a positive one.

Healionics (Redmond, WA) comes from the latter school of thought. Launched in 2007, the company custom engineers a technology dubbed the Sphere-Templated Angiogenic Regeneration (STAR) three-dimensional biomaterial scaffold, which is designed to facilitate healing while reducing foreign body response. "A lot of the materials out there are biocompatible," says Michel Alvarez, Healionics CEO. "We're beyond biocompatibility. We're into true healing and biointegration with host tissue."

Established to commercialize STAR technology, the company builds on the years-in-the-making biomaterial breakthrough achieved at the University of Washington Engineered Biomaterials group (UWEB; Seattle). There, UWEB codevelopers Buddy Ratner and Andrew Marshall discovered the 'sweet spot,' which Alvarez defines as "the precise pore geometry that creates these healing benefits." With this sweet-spot knowledge, Healionics is able to create a uniform and consistent porosity akin to a honeycomb structure on a given substrate using its proprietary sphere-templating process.

Measuring at least 150 µm thick, the resulting 3-D scaffold supports biointegration and tissue regeneration because the body reacts differently to the engineered porous material than it does to the solid form of the original material, according to Alvarez. And, because the pore geometry rather than the material itself is responsible for promoting healing, the technology can be used with a variety of substrates. Among them are implant-grade silicones and biodegradable hyaluronic acid. "We did not introduce some new formulation," Alvarez explains. "We just basically put a really precise and uniform porous structure to existing, well-established synthetic materials."

In addition to supporting angiogenesis, the STAR scaffold has demonstrated a significant reduction in foreign body response, according to the company. Promoting acceptance of a long-term implant by the body could be useful for such products as implantable glucose sensors, ophthalmic devices, stimulation leads, catheters, vascular-access ports, and a variety of additional applications.

Healionics

www.healionics.com

Booth #658

Copyright ©2009 Medical Product Manufacturing News

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)