Know your Plasticizers: A New Study on Plasticizer Migration

November 22, 2013

Phthalates such as di-(2-ethylhexyl)phthalate (DEHP) have been the most commonly used plasticizers in the medical device industry. Although they have been employed to ensure that PVC compounds achieve the desired flexibility, they have been associated with toxicity concerns, prompting manufacturers to demand alternatives. However, in addition to toxicity issues, plasticizers can migrate from PVC into adjacent non-PVC thermoplastics, causing stability problems. To address this phenomenon, Teknor Apex (Pawtucket, RI) has published a study focusing on plasticizer migration, which can affect a range of medical device components, including connectors.

"Most PVC applications are connected to a rigid non-PVC material, and that rigid material typically is more attracted to the plasticizer than the PVC device that we put it in," remarks Michael Roberts, business development manager in Teknor Apex's vinyl division. "The issue is that when the plasticizer comes into contact with a rigid material adjacent to it--unless that material is made of rigid PVC--it will tend to soften the connector or fastener, resulting in damage. This damage will look like environmental stress cracking, or crazing."

|

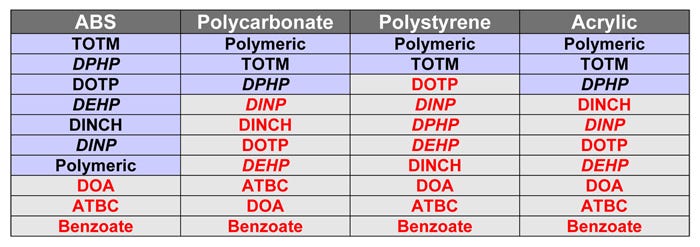

Plasticizers ranked by migration effects on plastics in contact with PVC. Plasticizers in red are not recommended for contact with the non-PVC materials. Those in italics are phthalates. (Source: Teknor Apex Co.) |

Focusing on four materials commonly used in conjunction with PVC--ABS, acrylic, polycarbonate (PC), and polystyrene (PS)--the study highlights the use of PVC tubing in conjunction with PC connectors. In such applications, according to the study, certain plasticizers can cause softening, cracking, or other defects in the non-PVC components as they migrate across the interface between the PVC and the connecting material. In contrast, other plasticizers exhibit little or no effect. The plasticizers discussed in the study include DEHP and diisononyl phthalate (DINP), both of which were rated marginal for contact with three of the four non-PVC materials; and DPHP, which was found acceptable for contact with three of them.

"One of the things that many customers started asking us about phthalate replacements was how new plasticizers migrate and how they react with non-PVC materials," comments Lou Cappucci, vice president and business manager in Teknor Apex's vinyl division. "They were concerned because some DEHP alternatives are known to have much higher migration rates. What medical device manufacturers will learn from our study is that by evaluating alternative plasticizers and PVC, they can compare and contrast how they will perform. Because many medical device manufacturers use DEHP today, what they're really asking is that if they move to another material, how will it perform relative to DEHP?"

Correction The original version of this article implied incorrectly that rigid PVC can be adversely affected by plasticizer migration. As Lou Cappucci notes, the Teknor Apex study informs people that almost all plasticizer materials to some extent craze or damage the hard materials that are connected to the flexible PVC. "One way to avoid this problem is to use rigid PVC instead of the non-PVC plastic," he adds. "Rigid PVC is the one rigid plastic that is minimally affected by migration of plasticizer from flexible PVC, and thus it presents manufacturers with a possible solution to the migration problem." |

Bob Michaels is senior technical editor at UBM Canon.

About the Author(s)

You May Also Like