How Lasers Make Super-Hydrophobic Materials

January 23, 2015

Researchers from the University of Rochester in New York have taken a significant step in developing hydrophobic materials, with a new technique that enables them to transform metals into extremely water repellent hydrophobic materials, all without the need for temporary coatings.

Super-hydrophobic materials have become increasingly desirable for a number of different applications such as rust prevention and anti-icing. Within medtech, hydrophobic materials are of interest for woundcare applications, surgical tools, and for protecting electronics exposed to moisture. However, most current hydrophobic materials rely on chemical coatings. That is, until scientists at the University of Rochester developed a technique that creates intricate patterns of micro and nanoscale structures to give metals a hydrophobic property, according to a news release from the university.

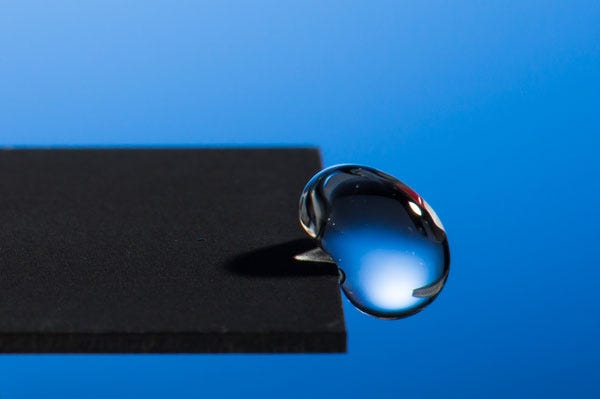

|

Hydrophobic material repelling a water droplet. |

The powerful and precise laser-pattern technique was built off of earlier research that the team performed that involved using a similar laser-pattern technique that turned metals black. Chunlei Guo and his colleague at the university's Institute of Optics, Anatoliy Vorobyev, believe that using this technique will enable them to not only create multifunctional surfaces that are super-hydrophobic, but also high-absorbent optically.

Understanding the significance of hydrophobic surfaces and the benefits that lie within are crucial to exploring the potential advantages and applications of such surfaces. Just last year a hydrophobic light-activated surgical adhesive was created that could help seal wounds and wet tissue without being compromised by an exposure to blood.

Of course, the largest significance of the new laser technique being developed in Rochester is that the hydrophobic structures created by the laser become an intrinsic part of the metal surface, meaning they won't rub off.

Researchers say that the materials created from the laser are so water-repellent that the water actually bounces off of the surface before eventually settling and rolling off. They even compared their surfaces to Teflon, a common hydrophobic material used on nonstick frying pans. Teflon kitchen tools are not super-hydrophobic, as they require that the surface be tilted at about a 70° angle before water begins to roll off. Meanwhile the surfaces created by the team's new laser-pattern technique can make water roll off when tilted at only a five degree angle.

Before the team can really explore the potential applications of these super-hydrophobic materials, they still have a few obstacles to clear. Currently, it takes the laser an hour to pattern a 1 × 1 in. metal sample, a process that is too time consuming to have much of an impact on major surfaces. Researcher are also exploring ways of applying the technique to non-metal materials in an effort to broaden the potential applications of the technology.

The research team believes that focusing on techniques such as this can give rise to multifunctional metals. Exploring the idea of hydrophobic surfaces on non-metal materials, such as semiconductors or dielectrics, could pave the way for transformative technologies such as water resistant electronics. While these kinds of developments could still be quite a ways down the road, solving these early challenges are an essential part of the equation that could have a lasting impact.

Refresh your medical device industry knowledge at MD&M West, in Anaheim, CA, February 10-12, 2015. |

Kristopher Sturgis is a contributor to Qmed and MPMN.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like