How 3-D Printing Can Live Up to Its Potential in Medtech

May 27, 2014

Imagine trying to change the course of a heavy-load freight train barreling ahead in the wrong direction. That train is a metaphor for the medtech industry's use of materials, says Michael Drues, PhD, president of Vascular Sciences (Grafton, MA; www.vascularsci.com). "Maybe we need a derailment," Drues says.

|

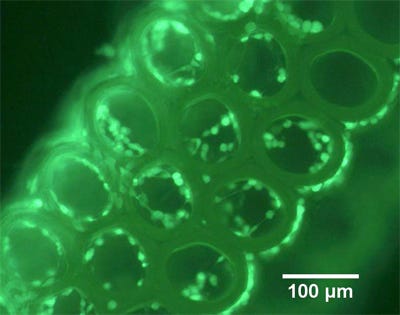

Engineered tissue scaffolds are an example of a promising medical application of 3-D printing. Photo courtesy of Regenerative Medicine 8, no. 6 (2013), 725-738. |

Traditionally, many medical device materials have been repurposed from household applications. MIT-based biomaterials pioneer Robert Langer has observed that many medical materials used throughout the 20th century had been inspired by household items. The use of polyether urethane in artificial hearts was inspired by device designers who thought that a girdle made of the materials had a good flex life--just like the heart. Decades later, the material is still used for cardiovascular applications.

Other household materials that have been recast as biomaterials include silicone--which has long been used as mattress stuffing; and the cellulose acetate used in dialysis tubing was previously used for sausage casing.

While commercializing devices with novel materials is no easy feat, the current approach of relying on tried-and-true but oftentimes suboptimal materials is holding back the medical device industry.

It is also one of the main things limiting the use of 3-D printing in medicine. 3-D printing has tremendous potential for creating everything from novel implantable medical devices, tissue, and drugs made from new molecular entities. By contrast, most of the current uses of 3-D printing in medicine are pretty boring, Drues says. "It is the low-hanging fruit."

To drive progress in 3-D printing, we need more than just biocompatible materials--we need biofriendly materials, Drues explains. "Biocompatibility means you put something in the body and the patient does not drop dead," he adds. The problem with current biomaterials is that they were never in a million years designed to go into the human body.

Hear Michael Drues, PhD, president of Vascular Sciences speak at MD&M East, June 9-12, 2014 in New York City. |

For true innovation, Drues recommends that engineers turn to nature for inspiration. "Begin with the body in mind. Try to understand how the body works first. We can learn so much if we look at the body and biology from an engineering perspective," he says. "Biology has solved many problems that we are trying to solve," he says. For example, instead of trying to print small-diameter blood vessels, Drues recommends printing the scaffolding for the tissue. That can be loaded with proteins or genes that can turn on the biological process of angiogenesis. "Now you have the best of both worlds," he says.

It is also worth looking at non-human organisms to find inspiration. "For instance, there are simple creatures like crawfish with open circulatory systems," Drues observes. "There might be situations where we don't need to create blood vessels."

It is important to ask the right questions with respect to 3-D printing, which promises to be a powerful platform technology for medicine--a real disruptive technology. In that regard, the medical device industry should let go of what it thinks it knows about biomaterials and 3-D printing and start from scratch. Adds Drues: "If Henry Ford would have asked his customers what they wanted, they would have said 'a faster horse.'"

Brian Buntz is the editor-in-chief of MPMN. Follow him on Twitter at @brian_buntz and Google+.

About the Author(s)

You May Also Like