Convenient Truths about Gas Plasma Technology

SURFACE MODIFICATION Plasma surface activation of PTFE tubing promotes adhesive bonding to hubs and connectors, enhances uniform adhesion of biocompatible coatings, and enables solid and permanent ink marking.

February 1, 2009

SURFACE MODIFICATION

|

Plasma surface activation of PTFE tubing promotes adhesive bonding to hubs and connectors, enhances uniform adhesion of biocompatible coatings, and enables solid and permanent ink marking. |

Fluoropolymers are a family of thermoplastic materials known for their remarkable physical and chemical properties. These materials have extremely low coefficients of friction, exceptional chemical resistance and biocompatability, and good mechanical strength. They also offer high melting points, low dielectric constants, and outstanding resistance to flammability. Not surprisingly, fluoro-polymers are used in a broad spectrum of applications that exploit their unique combination of properties, including medical devices and biomimetic implants. Perhaps the most well known of the synthetic fluoropolymers is polytetrafluoroethylene (PTFE), a fully fluorinated polymer more recognizable by its trade name Teflon.

Although the intrinsic bulk properties of PTFE are highly exploitable, manufacturers often encounter problems harnessing the material in device manufacture and assembly because of its surface properties. Bonding PTFE is indeed a problem—not just for adhesives, but also for inks, coatings, and biomaterials. This article describes how gas plasma surface modification has solved many of the compromises between the bulk and surface properties of fluoropolymers. It describes new plasma activation processes that provide fluoropolymers with increased bondability to adhesives, inks, and selective bio-materials. It also addresses controlled chemical surface functionalization, which holds particular relevance to PTFE in contact with biological environments, where surfaces need to be modified to promote the conjugation of bioactive molecules.

What Is Plasma?

Plasma is a state of matter just as a solid, liquid, or gas. Add enough energy to a gas and it becomes ionized into the plasma state. The active components of plasma include ions, electrons, radicals, excited species (such as metastables), and photons. The collective properties of these active species can be controlled and harnessed to perform various surface treatments such as nanoscale cleaning, activation for surface wettability, chemical grafting, and coating deposition.

Chemically, plasma is a highly reactive environment that is used to change the properties of surfaces without affecting the bulk material. The energy carried by this partially ionized gas can be controlled so that it contains low heat energy. This is achieved by coupling the energy into the free electrons rather than the heavier ions, and even allows for the treatment of heat-sensitive polymers such as polyethylene and polypropylene. The energy is often coupled into the gas by creating an electrical field between two electrodes at low pressures. This is the operating principle behind fluorescent lighting—only instead of using the light given off, the plasma's chemical properties are harnessed to treat material surfaces.

Plasma can also be generated at atmosphere (i.e., not requiring vacuum chambers or pumps). In the past, atmospheric plasmas were too hot to be used as a surface-treatment tool. Recently, however, technology has advanced to produce low-temperature plasmas at atmosphere that are suitable for treatment of even the most heat-sensitive polymers.

Adhesive Bonding and Ink Marking

The application of PTFE in the medical device industry is often limited because of the material's inability to be adhesively bonded to other materials. Its inherently low surface energy and poor polarizability mean that the surface cannot provide enough energy to bond with adherents such as adhesives and inks. Gas plasma surface modification solves this problem by increasing PTFE surface energies. This is achieved by defluorination along the –CF2–CF2– polymer chain, and with the addition or substitution of polar chemical groups onto the surface. Ammonia has been the traditional feed gas for PTFE surface activation by plasma. However, a new process involving alcohol copolymerization produces much better adhesion properties. In addition to promoting greater adhesion, this process also demonstrates significantly extended activation lifetimes.

|

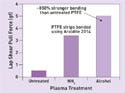

Figure 1. (click to enlarge) A comparison of lap shear forces of PTFE test strips bonded with Araldite 2014 as a function of different plasma treatments. |

Figure 1 compares the lap shear pull forces required to separate PTFE strips bonded to each other using Araldite 2014 epoxy adhesive following various plasma surface treatments. Ammonia plasma shows significant improvement over the untreated samples with lap shear forces 6.5 times greater. However, the alcohol plasma–induced copolymerization process improves bonding strength 1.5 times over ammonia and 8.5 times over the untreated surface. The failure mode appears to be between the adhesive and the PTFE. However, during in-house tests, x-ray photoelectron spectroscopy (XPS) revealed only fluorocarbon on both surfaces at the failure interface.

A previous study assigned bond failure to interfacial stress between the surface-modified PTFE and the bulk, as opposed to between the epoxy and the PTFE surface.1 The study suggested that adhesion properties are limited by the presence of a weak boundary layer. It can certainly be argued that plasma-induced chain scission can weaken the subsurface by reducing its bulk tensile properties. And because plasma activation is a surface-treatment technique, it is likely that chemical activation occurs at greater surface depths than chain scission. This suggests that the depth of surface modification is critical to adhesion promotion properties. Additionally, the study determined that increased adhesion properties after NH3 and H2 plasmas are related more to the degree of defluorination than to the presence of polar groups.

|

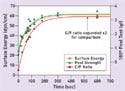

Figure 2. (click to enlarge) Surface energy, peel strength, and carbon/fluorine (C/F) ratio plotted against ammonia plasma exposure time. |

The graph in Figure 2 corroborates this suggestion by showing an exponential increase in peel strength (in gram force) consistent with a similar rate of increase in the carbon/fluorine (C/F) ratio as a function of plasma exposure time. However, a much closer correlation is observed between the surface energy and the peel strength. The surface energy relates not only to the surface fluorine concentration but also to the presence of surface polar groups.

|

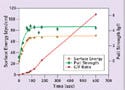

Figure 3. (click to enlarge) Surface energy, peel strength, and carbon/fluorine (C/F) ratio plotted against plasma-induced alcohol copolymerization exposure time. |

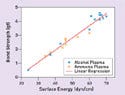

When a similar plot was compiled as a function of plasma-induced alcohol copolymerization, the correlation between surface energy and peel strength remained consistent while the C/F ratio became noncorrelated (see Figure 3). When the surface energy was plotted against peel-strength data from both ammonia and alcohol plasma processes, the straight line plot gave additional support to the correlation between PTFE surface energy and peel strength (see Figure 4). This suggests that the bondability of PTFE has a direct dependence on surface energy and is independent of the modes of surface energy change, defluorination, and polarization.

Treatment Lifetime

|

Figure 4. (click to enlarge) Bond strength versus surface energy for PTFE treated with ammonia plasma and plasma-induced alcohol copolymerization. |

Plasma-treated polymers age at different rates and to different extents according to factors such as their chain mobility and chemical reactivity with their environment. The aging characteristics of materials need to be understood with respect to their storage or application media. This information is an important manufacturing flow process consideration and critical for determining the maximum staging time of materials following plasma treatment before they wholly or partially revert to their inactivated state.

|

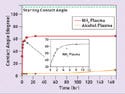

Figure 5. (click to enlarge) A plot of the water contact angle on PTFE as a function of time after exposure to ammonia plasma and plasma-induced alcohol copolymerization. |

The activation lifetime of plasma-treated PTFE has been the subject of numerous studies. After ammonia plasma processes, a previous study observed a partial reversion of PTFE hydrophilicity to a constant value when stored in air.2 These results have been repeated in this study (see Figure 5). The surface showed a shelf life of less than six hours before reverting to a water contact angle of just over 60°. Reorientation of the modified polymer chains essentially dissolves the plasma-grafted polar groups into the hydrophobic bulk, while at the same time orienting fluorine atoms toward the surface. The driving force for this is a reduction in overall surface free energy. Surface activation gradually deteriorates and places time constraints on downstream processing. In production environments, plasma-treated PTFE substrates need to be bonded or ink marked as soon as possible to lock the surface activation in place. PTFE activation lifetimes using ammonia plasma are measured in hours and thus regarded as having limited success.

Recent developments have overcome past shortcomings in PTFE activation lifetimes by extending them from hours to weeks, which facilitates the use of plasma in manufacturing environments. Figure 5 compares treatment lifetimes of ammonia plasma and plasma-induced alcohol copolymerization. The results of this study indicate a postprocessing window of approximately six hours. Plasma-induced alcohol copolymerization demonstrates activation lifetimes that extend beyond two weeks. Numerous works have been published on eliminating the time-dependent effects of plasma treatment by subjecting PTFE to surface graft copolymerization of acrylic acid. The studies have demonstrated the viability of this technique to permanently modify PTFE surfaces for increased wettability, bondability, and biocompatibility.3

Grafting Reactive Functionalities onto PTFE

Expanded PTFE (ePTFE) is a commonly used material for prosthetic implant applications. Its mechanical strength, impermeability to blood, and inertness to biofouling (the adherence of certain proteins that are forerunners to plaque buildup) make ePTFE ideal for various in vivo applications. For instance, its flexibility aids in healing, and catheter tubing made of PTFE doesn't kink very easily and generally has good compression resistance. For biomedical applications, the ability to modify PTFE surfaces is important for biocompatibility. For example, the adhesion of antithrombogenic enzymes such as thrombomodulin, urokinase, and heparin requires the PTFE surface to be first modified with chemical anchors such as carboxylic groups. Such groups provide covalent immobilization of these enzymes. Grafting these carboxylic groups onto PTFE has also been used for the covalent immobilization of chitosan, a compound useful for the purification of biomaterials.4

Epithelial cell growth can be encouraged on PTFE by providing active surface bonding sites. This enables the material to be used for blood-contacting devices such as vascular grafts, stents, synthetic heart valves, and other in vivo devices. A previous study investigated the use of biologically active collagen IV (CNIV) as a synthetic scaffold to promote the adsorption of endothelial cells to PTFE devices used for in vivo vascular implants.5 To couple CNIV to PTFE, the surface must first be activated by grafting hydroxyl functionality, followed by the covalent attachment of N-(3-dimethylaminopropyl)-N'-ethylcarbodiimide. All of this must be done while retaining the hydrophobic properties of the base PTFE. Retention of hydrophobic properties is important for surfaces that come in contact with blood because they are nonactivating to platelet adsorption (leading to the adsorption of fibrin).

|

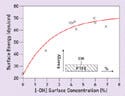

Figure 6. (click to enlarge) Data show that there is an exponential rise in surface energy as a function of increased surface concentration of –OH functionality. |

The study demonstrated that it is possible to graft polar functional groups to PTFE by plasma activation with only a modest loss in hydrophobicity. In our study, we plotted surface energies against the number of hydroxyl groups bonded to the surface (as a percentage of total surface species) following plasma-induced alcohol copolymerization on PTFE (see Figure 6). The surface energy can be controlled by limiting the amount of time that the substrates are exposed to plasma. For example, after 30 seconds of exposure to the plasma, we obtain a surface –OH concentration of 2% while the surface energy remains less than that of PEEK, which is about 41 dyn/cm.

Previous studies have modified the PTFE surface with amino functionality as a first step in the covalent conjugation of peptides that promote in vivo endothelialization.6 This process has particular relevance to arterial prosthesis. The surface concentrations of –NH2 groups were determined by surface derivatization of 5-bromosalicyclaldehyde. This compound has good graft selectivity to –NH2 groups. In addition, its bromine constituent, which is detected by XPS, can be used to calculate the –NH2 concentration using the following formula:

[%NH2] = ([%Br]/100–9[%Br]) × 100.

|

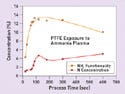

Figure 7. (click to enlarge) A comparison of nitrogen concentration with primary amine as a function of exposure time to ammonia plasma. |

This technique allows researchers to distinguish between primary amine functionality and other surface nitrogen–containing species. Consider the graph shown in Figure 7, which plots the N and –NH2 concentrations versus exposure time to ammonia plasma. Although the surface concentration of N increases to a maximum of ~13% after ~90 seconds, it then starts to decline with increasing exposure.

By contrast, –NH2 shows complex behavior and continues to increase with increasing plasma time. However, its evolution features an initial plateau between 30 and 60 seconds, followed by a peak at 120 seconds. A gradual increase of –NH2 functionality is observed between 200 and 600 seconds, maximizing at ~5% surface concentration. At these exposure times, –NH2 functionality accounts for ~50% of the total surface N, compared with ~30% after 100 seconds.

|

Figure 8. (click to enlarge) A comparison of the selectivity of primary amino groups to surface nitrogen. |

The results show that selectivity is very poor using this plasma process. Selective grafting of primary amines onto PTFE can be greatly improved by adopting the plasma-induced graft copolymerization technique using organic amines. Using this method, N:–NH2 ratios can be improved from 2:1 to 3:5. However, the process window is quite narrow and more work is needed to improve the selectivity and to broaden workable parameter ranges (see Figure 8).

Conclusion

Gas plasma technology can help improve the biomimetic and biocompatible properties of PTFE. Surface modification of PTFE using this technology can provide reactive chemical functionalities that promote the binding of adhesives and inks. Such functionalities also promote the conjugation of molecules that encourage biocompatibility. The material's adhesion properties can be dramatically improved using plasma-induced copolymerization techniques. This process shows significant improvements over ammonia plasma treatments. In addition, bonding strength has a direct relationship to surface energy—independent of the drivers causing the surface energy change. This principle has interesting implications for in vivo applications that require the preservation of low surface energies as specific chemical functionalities are grafted to PTFE.

Plasma-induced alcohol copolymerization of PTFE has also extended surface activation lifetimes. Downstream processing and staging time was once confined to a six-hour window, but it has now been extended beyond two weeks, providing more flexibility in manufacturing environments.

Finally, the concept of plasma-induced copolymerization offers new methods of chemically engineering surface properties of PTFE. The ability to selectively functionalize this surface with chemical groups such as primary amines, hydroxyls, and carboxylic acids means that engineers can now broaden their use of this material in medical technology.

Demetrius Chrysostomou, PhD, is director of technology for PVA TePla America Inc. (Corona, CA). Reach him at [email protected].

References

1. JP Badey et al., “Influence of Chemical and Plasma Treatments on the Adhesive Properties of PTFE with an Epoxy Resin,” International Journal of Adhesion and Adhesives 16, no. 3 (1996): 173–178.

2. DJ Wilson, RL Williams, and RC Pond, “Plasma Modification of PTFE Surfaces Part II: Plasma-Treated Surfaces Following Storage in Air or PBS,” Surface and Interface Analysis 31, no. 5 (2001): 397–408.

3. ET Kang et al., “Surface Modification and Functionalization of Polytetrafluoroethylene Film,” Macromolecules 29 (1996): 6872–6879.

4. H-X Sun et al., “Surface Modification of Poly(tetrafluoroethylene) Films via Plasma Treatment and Graft Copolymerization of Acrylic Acid,” Desalination 192, no. 1 (2006): 271–279.

5. NS Ludwig et al., “Directed Type IV Collagen Self-Assembly on Hydroxylated PTFE,” Journal of Biomedical Materials Research 78A (2006): 615–619.

6. V Gauvreau and G Laroche, “Micropattern Printing of Adhesion, Spreading, and Migration Peptides on Poly(tetrafluoroethylene) Films to Promote Endothelialization,” Bioconjugate Chemistry 16, no. 5 (2005): 1088–1097.

Copyright ©2009 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)