Bacteria No Match for Nonstick Medical Device Material

February 17, 2015

A new solid silicone-infused polymer joins an arsenal of slippery, nontoxic surface coatings used on medical materials to prevent infection.

Kristopher Sturgis

|

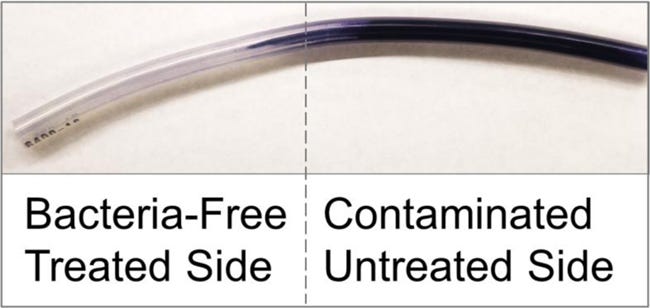

A bacteria-killing coating could be especially useful for catheters. Image from Harvard. |

These biofilms, where bacteria accumulate into adhesive colonies, are a common occurrence on the surfaces of medical devices, leading to infection and oftentimes rejection of the implant. Recently, researchers at Harvard University developed a potential solution, when they created a slippery surface coating for medical materials that significantly reduces bacteria's ability to accumulate and colonize on the surface. The breakthrough could be especially useful for reducing catheter-related infections.

The study indicates a new approach to fighting off bacterial infections that result from implanting medical devices into the body. An approach that involves a powerful, long-lasting surface repellent technology that can be used on virtually any medical material to prevent infections brought on by biofilms, according to a Harvard press release.

The technology uses the molecular structure of polymers, providing the ability to collect and store considerable volumes of lubricating liquids in their molecular structure, like sponges. This allows for the absorption of a larger reservoir of lubricant, which can travel to the surface and render it continuously repellent by creating a slippery environment. This slippery environment prevents bacteria from accumulating and colonizing.

In their current study, researchers have explored the benefits of a solid silicone polymer--the same kind already in use in many of today's medical tubing--saturated with a liquid silicone oil. Each component is both safe and nontoxic, and are already used in many medical devices, as well as many common cosmetic products.

The findings were reported from a team of researchers led by Joanna Aizenberg, professor of Materials Science at Harvard's School of Engineering and Applied Sciences (SEAS). This same team of researchers made headlines with the development of other slippery surface technologies, including the Slippery Liquid-Infused Porous Surfaces (SLIPS) technology, a surface coating inspired by the carnivorous pitcher plant that can virtually repel any liquid or solid material. SLIPS eventually inspired the invention of TLP coating, a surface repellent that uses materials compliant with FDA standards to prevent bacterial build-up on medical implants.

"My team has pioneered the broad idea of slippery surfaces that provide antifouling behavior due to the presence of lubricant overlayer," Aizenberg said. "I believe that this technology will be especially useful in indwelling catheter materials that are currently plagued with bacterial colonization and the associated infections. These liquid-infused polymers have unmatched antifouling and infection-reducing potential without the use of bacterial agents, thus reducing excessive antibiotic usage and the associated antibiotic-resistant microbial communities.

It was in the process of saturating the silicone tubing with silicone oil, that the team realized the potential power of the two materials working together. The saturation process enables the liquid-infused polymer to withstand sterilization methods, providing it the power of durability, specifically the ability to be used again and again over time without compromising the effectiveness of the surface coating. The silicone oil continuously diffuses to the surface, replenishing itself to replace any oil that is pulled away by liquids flowing against it. Fluids such as urine, blood, gastrointestinal fluids, or any other bodily fluids will be able to interact with the surface coating without jeopardizing the slippery nature of the surface.

"We chose silicone oil-infused silicone in our study simply due to the fact that both the tubing and the oil are commonly used and FDA-approved biomedical materials," Aizenberg said. "Their combination brings about a much higher level of anti-bacterial protection.

As for the future, Aizenberg and her team believe this technology could have an impact across a range of different fields. The repellent properties could provide relief for other materials plagued with biofouling problems from waste-water management systems to maritime vessels and oil pipe systems. Aizenberg's goal is to continue to improve the various surface coating technologies so that each have their own unique properties that can be applied to a lot of different surfaces, increasing its functionality.

"We are exploring the concept of effective liquid-based polymer systems quite broadly," she said. "A number of other 'designer' polymers are being currently developed and will be reported on soon."

Refresh your medical device industry knowledge at BIOMEDevice Boston, May 6-7, 2015. |

Kristopher Sturgis is a contributor to Qmed and MPMN.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like