Machining Equipment 16084

October 1, 1998

Machining Equipment

Pneumatic cutter

A pneumatic jumbo cutter is designed to cut round material up to 1 in. diam and flat material up to 3.34 in. wide. The JC 3985's powerful feed belts can transport material at a rate of 16 to 195 ft/min, pulling wire directly from a spool or drum. It can also be integrated with the manufacturer's PF 2000 electric demand prefeed, which accommodates larger spools and provides greater feeding control. The cutter, providing 150 lb of pull force and a cutting force of 600 lb, processes wire, steel cable, metal strips, tubing, and sleeving. Schleuniger Inc., 87 Colin Dr., Manchester, NH 03103.

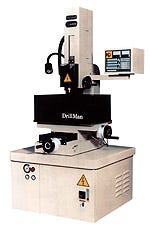

EDM system

A special-purpose EDM system can drill holes ranging from 0.012 to 0.118 in. diam through any conductive material using ordinary tap water as a dielectric. The HS-1 DrillMan features cutting depths up to 200x hole diam and penetration rates as fast as 1 in. in 30 seconds. The machine's applications range from start holes for wire EDM jobs to production jobs, such as safety wire holes. Multiple holes can be accurately positioned using the edge-find feature from a reference surface, and the x-y digital readout enables accurate hole spacing. Hansvedt Industries Inc., P.O. Box 6099, Urbana, IL 61801.

Automatic lathes

Single-spindle automatic lathes feature a parallel numerical control (PNC) system and TB-Deco software. The PNC technology replaces mechanical cams by creating electronic paths to the individual tool holders, all controlled by a clock. The TB-Deco software, run on Windows, controls all aspects of machining and can be programmed on any PC. Three different models (20, 10, and 7 mm) of the Deco 2000 series are offered in four different axial configurations. Specifications for the 20-mm version include maximum workpiece lengths of 200 mm, headstock spindle speeds up to 10,000 rpm, and a 5.5-hp motor. Tornos Technologies U.S. Corp., 70 Pocono Rd., Brookfield, CT 06804.

Machining system

A machining center can be configured with a variety of main and auxiliary spindles, fourth axes, and productivity and precision enhancing options to meet specific machining needs. With axes travels of x = 32 in., y = 16 in., and z = 20 in., the BostoMatic 32 is suitable for machining small to medium-sized precision parts. The machine's control has a processing speed of up to 1100 five-axis blocks per second for hesitation-free contouring at feed rates up to 450 in./min (787-in./min rapid transverse) on even the most data-intensive part programs. Boston Digital Corp., 125 Fortune Blvd., Milford, MA 01757.

Grinding system

Geared for high-level production and accuracy, a centerless abrasive belt grinding system is offered with numerous advantages over bonded wheel grinding. The Model 1212 heavy-duty, high-precision system is designed for the sizing and finishing of a variety of cylindrical parts, and features high stock removal and feed rates, constant grinding surface speed, cool operation, and no in-process wheel dressing. The grinding and tool-polishing belts can be quickly and easily changed in a 2-minute operation. Acme Manufacturing Co., 650 W. 12 Mile Rd., Madison Heights, MI 48071.

Laser micromachining equipment

Micromachining equipment based on solid-state laser technology is designed for micromachining ceramics, semiconductor materials, and polymers with spot sizes less than 25 µm. Typical applications of the Impressario series are microcutting, microetching, high-speed microdrilling, micromilling, and microtrimming of materials with a resolution of less than 10 µm. The micromachining tools are available in both traditional arc lamp and diode-pumped versions. The exact wavelength and cavity design will be a function of the specific micromachining application. Resonetics Inc., 4 Bud Way #21, Nashua, NH 03063.

Fineblanking system

Integrated finish and cleaning systems make automated cellular fineblanking possible, even for flexible manufacturing environments. The single-fluid systems perform deburring, surface and edge finishing, cleaning, cooling, drying, and rust protection of fineblanked parts, all in a continuous process. They allow the efficiencies of complete, automated cellular processing—from coil to finished fineblanked parts—while producing different part configurations in flexible batch sizes and schedules. Feintool Cincinnati Inc., 11280 Cornell Park Dr., Cincinnati, OH 45242.

Electric spindle

An electric-powered, 2000–40,000-rpm spindle system is made for 1/8-in. and smaller end-milling and drilling-plus-microslitting, chamfering, and grinding on retrofitted CNC and transfer machines. The Astro-E400 system consists of a 210-W brushless dc micromotor; a straight 1.181-in.-diam spindle; and a power unit that controls speed, motor cooling air, forward and reverse operation, sequence of operations, and other functions. An integral sequence control system permits one power unit to control the operation of three different micromotor spindles using 24-V commands downloaded from host CNC machines. Integral electronic sensors provide torque feedback from the cutting tool to the power unit to maintain constant cutting speed under varying loads, plus an automatic motor stop to prevent overloads. NSK America Corp., 700 Cooper Ct., Ste. B, Schaumburg, IL 60173.

CNC cylindrical grinder

Designed to meet the rigorous demands and exacting requirements of high-production grinding, a CNC cylindrical grinder features a 24-in. wheel and a 25-hp wheel-head motor, allowing for aggressive stock-removal rates and improved cycle times. Other features of the Model 324S include a straight wheel head, 16-in. swing, 32-in.-between-centers distance, GE Fanuc 18TB CNC control, and vibration-damping base design. Weldon Machine Tool Inc., 1800 W. King St., York, PA 17404.

You May Also Like