The 10 Most Innovative BIOMEDevice Boston Suppliers

March 15, 2016

An affordable professional-grade 3-D printer and an automatic interactive quoting system for prototyping are but some of the innovations among the 10 BIOMEDevice Boston Innovation Prize semifinalists. Help us pick the five finalists that will compete at the April 13-14 show.

Chris Newmarker

Motors, operating systems, cables, coatings, 3-D printers, software--there are many innovations to be had on the floor of a major UBM medical device show such as BIOMEDevice Boston. Any one of them could potentially enable important medical device innovations.

What do you think are the most important types of innovations? Qmed's editors have selected 10 semifinalists for the BIOMEDevice Boston Innovation Prize. Check them out, and then answer our survey to help us pick the five finalists competing at the show.

Alpha Wire (Booth #335)

Cables for Tinier Medical Devices

Alpha Wire (Elizabeth, NJ) is touting its micro-coaxial cables, which it says are ideal for miniature video signal requirements. The cables, available starting in April, utilize high-strength alloys. They could aid in a wide range of applications, from sensitive medical imaging to minimally invasive medical devices such as endoscopy. Standard sizes range from 32 down to 50 American wire gauge.

Alpha Wire says in its entry: "While there are other micro-coaxial cables on the market, Alpha Wire is offering standard sizes in stock from 50 to 32 AWG and custom composite designs as well. The competition focuses mostly on custom and not off-the-shelf SKUs."

|

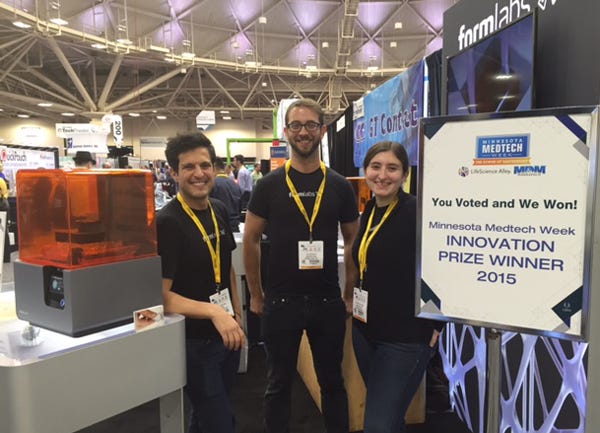

From left to right, the Form 2 3-D printer, Jory Block of Formlabs sales, JP Shipley of Formlabs marketing, Teresa Atwood of Formlabs operations, and the sign touting their winning of the Minnesota Medtech Week Innovation Prize. (Photo by Chris Newmarker) |

Formlabs (Booth #1113)

An Affordable Professional-grade 3-D Printer

Formlabs (Somerville, MA), which has a professional grade 3-D printer called the Form 2 that costs $3,499, won the Minnesota Medtech Week Innovation Prize in November after impressing a tour group of attendees at the Minneapolis show. They're hoping to repeat the same feat in Boston.

The Form 2 uses a precisely guided laser to cure a photopolymer resin. The company boasts that the technology allows for unprecedented accuracy and precision at an affordable price point. Such stereolithography 3-D printing technology has run into the tens of thousands of dollars in the past.

"The Form 2 keeps production in-house. In a few hours, you can create multiple high-resolution prints at a low cost. This process is much cheaper, faster, and easier," the company boasts in its entry.

Keyence Corp. of America (Booth #740)

An Instant Measurement System to Reduce Inspection Time

Keyence Corp. of America (Woodcliff Lake, NJ) says its IM-6225 instant measurement system--released in September 2014--does away with the need for optical comparators, hand calipers/micrometers, measuring microscopes, and GD&T and profile measurement systems.

"The system has the ability to identify the part, pull up the correct program, and measure up to 100 dimensions per part on up to 100 parts on the stage at once," Keyence says in its entry. "The system will automatically adjust the lighting, focus, and re-positions the program to match each part on the stage. It recognizes the profile and reflective images of each part, compares it to pre-programmed tolerances, produces a pass or fail for each dimension, and saves the data locally or to a network. Finally with one more button press, it prints out a full inspection report. All of this being accomplished in 3 seconds!"

Maxon Precision Motors Inc. (Booth #412)

Easy and Fast Motor Customization

In November 2015, Maxon (Fall River, MA) introduced its ECX program, which is built around a line of high speed, sterilizable motors for medical device applications such as hand held tools, respirators, and instrumentation.

The company says in its entry: "Maxon's X program offers design engineers the ability to customize their micro drive online quickly and easily. The configurator provides a step by step assembly of the DC drive based on the design engineers' specifications. They can configure the gear stages, the motor bearings, the shafts, the encoder, and much more. Mechanical and electrical data, dimensional drawings, and CAD files can be downloaded immediately after the configuration has been completed. Maxon's lean automated process ensures that all drive versions are ready for shipment within 11 days."

MTD Micro Molding (Booth #437)

Molding Super Tiny Medical Device Parts

MTD Micro Molding (Charlton, MA) specializes in molding tiny parts for the medtech industry. The company claims it has a unique advantage because it has the tool builder, process engineer, metrologist, and automation group all under one roof. Says the company: "If we run a mold and have an issue, we can get our tooling people together with the molding engineers to compare notes and make improvements on the fly. Revisions are made instantly, and we apply that learning as we go forward, so we won't make the same mistake again."

ProPlate/Professional Plating Inc. (Booth #155)

A Coating-based Braided Catheters Innovation

After becoming an MD&M West Innovation Prize finalist last month with its Torq-Lok braided catheter coating innovation, ProPlate (Anoka, MN) is back as a finalist for the Boston competition. Torq-Lok debuted 2014. The patented process atomically bonds metal directly to each braid pic, fusing them together as one at each crossing. Preliminary testing of Torq-Lok compared to non-coated braids demonstrated a range of 30-66% greater torque response, a 66% increase in torque to failure, and a 90° twist increase, according to ProPlate. Torq-Lok could allow for more braided catheter innovation because it allows for the braid pic count to be reduced. This, in turn, reduces material costs and production time for the braid manufacturers.

ProPlate has also been innovative in other ways. Its Vizi-Band metal coating process allowed it to become a Minnesota Medtech Week Innovation Prize semifinalist last year.

Proto Labs (Booth #304)

An Automatic Interactive Quoting System for Prototyping

Quick-turn manufacturer Proto Labs (Maple Plain, MN) was runner-up for the MD&M West Innovation Prize with its automatic interactive quoting system for prototyping.

ProtoQuote is an automated interactive quoting system. It had its latest software version released last year. Using ProtoQuote, medical device engineers can upload their 3-D CAD model and receive free design for manufacturability analysis and real-time pricing information within hours. ProtoQuote enables OEM engineers to make needed prototype modifications early and often, according to Proto Labs.

Proto Labs says in its entry: "The software has been continuously enhanced to now offer a very detailed design analysis including an interactive three-dimensional image, which allows developers to review their part geometry and assess any potential design issues that are highlighted. The process is so automated that these interactive quotes are provided within hours."

RTP Co. (Booth #333)

|

Image courtesy of RTP Co. |

Thermoplastics to Stand Up Against Hospital Disinfectants

RTP Co. (Winona, MN) in May 2015 announced the development of its RTP 2000 HC series of thermoplastic compounds. The RTP 2000 HC series is meant to stay tough when it comes to hospital disinfectants, maintaining strength, functionality, and integrity after repeated exposure. Based on a proprietary alloy technology that combines resins and additives, the RTP 2000 HC plastics open up new possibilities, according to RTP. "The RTP 2000 HC series provides a viable solution to a widespread problem: the damage and premature, catastrophic failure of plastic devices, equipment, and housings caused by harsh cleaners and disinfectants used in medical settings," the company says in its entry.

The plastics could enable better design of devices such as mobile ultrasound and x-ray machines, enteral feeding devices, drug infusion pumps, blood filtration equipment, and more.

The RTP 2000 HC series allowed RTP to become a semifinalist for the Minnesota Medtech Week Innovation Prize last year.

SUSE (Booth #405)

Live Operating System Patching

Enterprise Linux company SUSE (Cambridge, MA) has pioneered technology to perform "live patching" that does not require a reboot of kernel. SUSE says in its entry: "Using live patching, you can easily apply a kernel patch when you need to and not wait for a system shutdown." The live patching technology was part of the SUSE Linux Enterprise 12 Service Pack 1 introduced in recent months.

The live patching is beneficial for medical device OEMs because it increases service availability, reduces planned or unplanned downtime, and maintains security and stability, according to SUSE. The company was an MD&M West Innovation Prize for innovations related to the SUSE Linux Enterprise 12 Service Pack 1.

Vention Medical (Booth #632)

A Universal Handle for Medical Devices

Vention Medical (Marlborough, MA) is touting its Versatility universal handle, a 0-24 Fr handle that can be incorporated into a steerable device, catheter, or sheath. Vention says in its entry: "The Versatility universal handle eliminates the need to design and tool a handle in-house, so you can test concepts faster."

The handle became available in September 2014, and the mini handle was launched in January 2016.

Create your own user feedback survey

Chris Newmarker is senior editor of Qmed and MPMN. Follow him on Twitter at @newmarker.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like