Assessing Cleanroom Compatibility of Injection Molders

CLEANROOM TECHNOLOGY

|

Photo by iSTOCKPHOTO |

The suitability of electric versus hydraulic machines for cleanroom production has been hotly debated. Those in favor of electric machines point to the potential for hydraulic fluid to contaminate parts. Supporters of hydraulic machines cite the electric's possibility for particulate generation from drive belts and other power transmission elements.1,2 Nevertheless, it has gradually become accepted wisdom that electrics are the most suitable selection for a medical cleanroom.3,4

Medical devices are subject to stringent and comprehensive regulations for their manufacture. For most device classes, contamination control is achieved through the use of a cleanroom facility. Because medical molding is subject to validation (i.e., as noted by the Global Harmonization Task Force, SG 3 Guide), machine operations in controlled environments are subject to scrutiny, requiring documented proof that specified standards for environmental control are met. In other words, particulate emissions from the molding process that could affect product quality must consistently be kept within specified limits.

With respect to contamination control, FDA regulation 21 CFR 820.70(c) requires that “. . . where environmental conditions could reasonably be expected to have an adverse effect on product quality, the manufacturer shall establish and maintain procedures to adequately control these environmental conditions.”

Not much science-based criteria seem to exist relating to the evaluation of cleanroom compatibility of medical molding machines, although many unsubstantiated claims have been made on the subject. Using experiments and resulting in-depth analysis, this article describes a procedure developed for assessing compatibility, based firmly on the principles of ISO 14644–1:1999, “Cleanrooms and Associated Controlled Environments—Part 1: Classification of Air Cleanliness.”5

Cleanroom Molding Fundamentals

Cleanrooms provide control of airborne particles to levels that are appropriate for contamination-sensitive manufacturing activities. The sterility of parts produced during the manufacturing process and the cleanroom compatibility of the process and equipment are separate issues.

A sterile environment is one that is free from microorganisms and their spores. A clean environment is one where the concentration of contaminating particles, particularly airborne particles, is controlled to predefined limits. An environment may be clean without being sterile and vice versa.

|

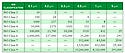

Table I. (click to enlarge) Selected airborne particulate cleanliness classes for cleanrooms and clean zones. |

Cleanrooms can be classified to a number of standards, the most common being ISO 14644, which is an international metric standard with classification based on the maximum allowable concentration of particles greater than 0.1 µm per cubic meter of air (see Table I).

Compliance to a specific class can be made at particle sizes between 0.1 and 5.0 µm depending on cleanroom class, design, and process requirements.

ISO 14644-1 has been used as the classification standard in which the airborne particle concentration limits decrease from ISO Class 9 through ISO Class 1. Most medical molding is performed in a Class 8 environment (i.e., less than 3,520,000 particles at 0.5 µm and greater per cubic meter of air), although there is an increasing trend toward Class 7, Class 6, and cleaner environments.

Particulate cleanliness classification is normally determined using a discrete particle counter (DPC) and a specified sampling protocol, with sampling sites located on an evenly distributed grid at a height determined by the work activity. A cleanroom is considered compliant if the average concentration at each location, and the 95% upper confidence limit (required if there are fewer than 10 locations), do not exceed the particle concentration limits of the specified ISO class at the considered particle size.

ISO 14644 and other cleanroom standards are performance requirements. They do not contain the information or procedures necessary to evaluate the particle contribution generated from equipment used within cleanroom environments. Because no procedure examples could be found for the medical molding environment, the protocol for the studies was based on methodologies described in ISO 14644.

The maximum concentration limit of particles per cubic meter of air in an operational cleanroom includes the background count of the cleanroom, as well as all particles generated within it. Particles generated by equipment will be in addition to those particles already present in the cleanroom. Therefore, even equipment that generates relatively few particles may not be compatible with a cleanroom that is already approaching the particle concentration limit for its class (i.e., one with little “headroom”).

ISO 14644 requires all classification statements to include the occupancy state of the cleanroom being assessed. These states are as built, at rest, and operational.

The as built condition addresses the performance of an unoccupied cleanroom's environmental systems. In this case, measurements can only be performed prior to production equipment being installed.

The at rest condition includes any installed equipment that is powered and ready to operate without personnel present.

The operational state includes any cleanroom personnel with installed equipment in normal production. The cleanroom compatibility of production equipment should be assessed or specified only under well-defined operating conditions.

Cleanroom airflow can be characterized as unidirectional (laminar), nonunidirectional (turbulent) or mixed (combination of unidirectional and nonunidirectional zones) flow. Cleanrooms classified at ISO Classes 6, 7, and 8, which include most medical molding cleanrooms, are typically nonunidirectional airflow designs with average room air change rates that can range from less than 30 to more than 250 changes per hour. However, due to the turbulent nature of the airflow in such cleanrooms, the air change rate may be many times the room average in one location, yet virtually nonexistent in another location. Unidirectional flow cleanrooms commonly used for pharmaceutical and microelectronic production are typically designed with air change rates often in excess of 700 per hour, also providing uniform air velocity throughout the entire room.

The concentration of the particle contribution from injection molding equipment will vary with the different volumes of air into which it is released (diluted). A decrease in volume will cause an increase in concentration and vice versa. The ability to calculate the volume of air affected by an injection molding machine in nonunidirectional airflow environments is entirely dependent on local installation conditions. In our analysis, particle concentrations were normalized to account for the individual machine dimensions within the test enclosure.

Room air change rates are often the basis for system design of a non-unidirectional cleanroom to target the cleanliness level of the area. However, this rate cannot be relied upon to determine the particle contribution from a machine into the immediate area surrounding the installed location within that cleanroom. The air change rates discussed in this article do not necessarily pertain to the average air change rate for the cleanroom as a whole. Rather they pertain to the environmental conditions that must exist locally to the equipment itself.

In other words, the calculated particle generation diluted by one local air change has been used as the basis for calculating the particle concentration dilution at the cleanroom cleanliness levels indicated. The particle contribution in any environment can be calculated if the local air change rate or volume of air into which particles can migrate from the injection molding machine can be empirically determined.

It is the nature of the medical device that determines the cleanliness requirement of the environment in which it is produced—Class III device manufacture would normally be done under greater particle control than Class I devices. To demonstrate compatibility with the cleanroom class that has been validated for production, the particle emission of the injection molding machine used to produce a part must be scientifically characterized and appropriately documented. In assessing the compatibility of a machine for cleanroom use, it is also important to understand that the measurement of its particle generation characteristics can only be achieved by dilution with a known volume of air.

Test Enclosure

The testing protocols developed by the study authors include the measurement, evaluation, and comparison of the particle generation characteristics of four injection molding machines. Two were small all-electric machines popular in medical molding and two were small hybrid presses. All machines were approximately the same clamp tonnage and screw diameter. In all tests, the same four-cavity mold and high-density polyethylene resin were used.

A clear paneled test enclosure was constructed with cross-sectional dimensions that caused the entire volume of high-efficiency particulate air (HEPA) filtered (99.99% efficient at 0.3 µm) supply air (≈175 m³/min) to become the diluent for all particles generated by the injection molding machine under evaluation. The horizontal unidirectional airflow design was selected because of the impracticality of collecting representative particle concentration samples from the total airflow in a vertical airflow environment downstream of (i.e., below) the injection molding machine.

Samples were taken at nine points on a vertical grid in the 7.3-m2 air exit plane of the enclosure. All samples were normalized to the number of particles per cubic meter of air. These data were then used to calculate the number of particles generated into the volume per minute of clean air local to the machine being tested.

|

A Husky ISO 4 laminar airflow cleanroom enclosure, with a HEPA filter bank at the rear of the unit. |

The test enclosure provided an environment that was classified to ISO 14644-1 Class 4 (Federal Standard 209E Class 10) at 0.5 µm and greater particles as built. This performance provided an extremely low background particle concentration level, assuring the most accurate possible airborne particulate data collection. This enclosure is probably the cleanest environment currently in use in the injection molding machine vendor community.

Particulate Tests

Prior to each test series, each of the four machines was subjected to the same independently conducted gross and fine cleaning procedures. The enclosure was fine cleaned with each change of machine. To verify conditions after a one-hour stabilization interval, the background particle concentration was measured in accordance with ISO 14644 procedures while the machine was unpowered (cold) and without services. A complete series of particle concentration measurements was then conducted at rest with the machine fully powered, but idling at full operating temperature and with all services active. The series of tests was then repeated in the operational condition with the machine cycling and producing parts.

Initial (Phase 1) operational tests were run at the maximum cycle rate (≈4 seconds) on all machines and are considered to be the worst-case particle generation scenario. A second series of tests (Phase 2) were conducted on the two hybrids, repeating the 4-second cycle rate, as well as 8- and 12-second cycles. This was done to characterize the particulate generation characteristics at cycle rates deemed more representative of medical molding conditions. These two machines were then equipped with an experimental particle containment system and reevaluated at identical cycle rates.

|

Figure 1. (click to enlarge) The first series of at rest results. |

Phase 1 Results–Comparing At Rest to Operational Variations. The first series of at rest results (Phase 1) are shown in Figure 1. In the figure, they are superimposed upon the concentration limits for ISO Classes 8 through 5, and defined by the typical air change rates used in the design of cleanrooms for these cleanliness classes.6 All particle concentration references are for particles 0.5 µm and greater in size per cubic meter of air.

Electric machine 1 (E1) had particle generation characteristics that were within the particle concentration limits of ISO Classes 8 through 5. It should be noted that electric machine 2 (E2) and hybrid machine 1 (H1) showed similar particle generation characteristics that were well within the concentration limits for ISO Classes 6, 7, and 8 with some compatibility at Class 5. Hybrid machine 2 (H2) exhibited particle generation characteristics that were within the concentration limits for ISO Classes 7 and 8.

The Phase 1 operational results were entirely different. These results underlined the need to measure the particle generation of machines under production conditions for a realistic assessment of cleanroom compatibility. Operating at a cycle rate of approximately 4 seconds, machines E2 and H1 were both clearly compatible with ISO Class 8 (with maximum allowable cleanroom background particle concentrations of 86% and 77%, respectively). Hybrid machine H1 was compatible with ISO Class 7 as well as ISO Class 8. Machine H2 was also compatible with Class 8 but with a background particle concentration headroom of 5%, which is too close to the class limits to be considered truly compatible.

It is interesting to note that the E2 tests, found to be the most compatible at rest, far exceeded the particle concentration limits for all ISO 14644 cleanliness classes in production.

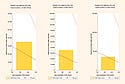

Phase 2 Results–Correlation Between Cycle Rate and Machine Particle Generation. The second series of tests (Phase 2) demonstrated that cycle rate has a direct impact on machine particle generation. These tests provided data suggesting that the particle generation from these machines is inconsistent, since the performance of both hybrid machines at the 4-second cycle rate was significantly improved when at rest and operational.

Correlation between cycle rate and particle generation is clearly evident for machine H1. At any cycle rate, this machine is well within the particle concentration limits for ISO Classes 7 and 8, with a minimum background particle concentration headroom corresponding to 58% of the Class 7 concentration limit at the 4-second cycle rate. The air change rate of 60 changes per hour for this class is typically the lowest design air change rate used at this cleanliness level.

|

Figure 2. (click to enlarge) Phase 2 of the tests showed that cycle rate has a direct effect on machine particle generation for machines H1 and H2. Because of the wide range of measurements, please note the change from thousands to millions for particles per cubic meter. |

The same cycle rate dependency is evident at ISO Class 8 for machine H2. When operated at the 4-second cycle in Phase 2, performance improved from the 5% maximum background particle concentration headroom, calculated during the Phase 1 tests, to 57%. The maximum background limit increased to 75% when the cycle rate was reduced to 12 seconds. Machine H2 is also compatible with ISO Class 7, allowing 13 to 51% of the class limit as headroom, depending on the local air change rate (see Figure 2).

|

Figure 3. (click to enlarge) An experimental PCS affected the particle generation characteristics of the hybrid machines. |

The addition of the experimental particle control system (PCS) also had a dramatic effect on the particle generation characteristics of both hybrid machines. Machine H1, equipped with the PCS, achieved an unexpectedly high degree of compatibility at all ISO Classes from 8 through 5. This included a remarkable background particle concentration headroom of 73% with the 4-second cycle rate at ISO Class 5 with 450 air changes per hour (see Figure 3). Such an air exchange rate would only be found in non-unidirectional cleanrooms operating at this cleanliness level. ISO Class 5 unidirectional cleanrooms typically have between 600 and 720 air exchanges per hour.

|

Figure 4. (click to enlarge) The performance of the H2 machine was influenced by the PCS. |

The PCS also influenced the performance of machine H2. Compatibility was extended to very acceptable levels for both ISO Classes 8 and 7 (see Figure 4). Fair compatibility to ISO Class 6 was achieved, except at the worst case 4-second cycle rate (see Figure 5).

Sources of Contamination

|

Figure 5. (click to enlarge) H2 machine performance testing showed fair compatibility to ISO Class 6, except at the 4-sec cycle rate. |

A preliminary investigation of the primary sources of particulate generation was made on both hybrid machines. The DPC was used at several locations, while the machine was operating and with machine covers in place. Because these tests were diagnostic and relatively informal, results could not be referenced to any standard of cleanliness or to each other. Additionally, there was no protocol developed to isolate the potential contribution generated from the technician performing the measurements who, by necessity, was in relatively close proximity to most of the sampling locations.

As expected, both machines generated high particle concentrations in and around the injector nozzles and within the clamp/mold enclosures. Machine H1 used a serpentine belt in the clamp enclosure, and some particle generation appears to be related to the movement of this belt.

No large particle generation source could be directly attributed to any of the components of the hydraulic systems on either of these machines. Nevertheless, we could find no way to determine whether they are a contributing factor to the concentrations measured within the clamp/mold enclosures.

None of the hydraulic components outside of the clamp enclosures generated significant particle concentrations, including the pumps, motors, and even the hydraulic fluid tank vents.

It was discovered that moving and cleaning the injector nozzles after purging resulted in the differences in machine particulate generation. This result was despite identical test conditions during Phase 1 and Phase 2 at the 4-second cycle rate, and on different days during cycle rate tests throughout Phase 2. Nozzle setup and cleaning may have been a factor that contributed to the difference in results of Phases 1 and 2.

Conclusion

Testing concludes that the cleanroom compatibility of an injection molding machine, or any other piece of production equipment, should be assessed only under well-defined operating conditions and not at rest. Given that there is a significant correlation between machine cycle rate and particle generation, compatibility statements should be qualified with reference to this factor. The air change rates referred to in any compatibility statement should pertain to the environmental conditions that exist locally to the equipment itself and not necessarily to the average air change rate for the cleanroom as a whole.

No evidence could be found to support the view that electric machines are inherently more suitable for medical cleanroom applications. Testing concluded that in many cases hydraulic machines are equally, if not more compatible, and are able to demonstrate compliance to the most stringent ISO standards.

The simple particle containment system was shown to decrease machine particle generation by at least an order of magnitude. In fact, the hybrids fitted with these systems were able to demonstrate compatibility to ISO Class 6 or better. Moreover, the hydraulic systems of the two hybrids examined demonstrated no significant contribution to the measured particulate load of the test environment. The setup of the injector nozzle seems to be a more important factor in machine particle generation than whether electric or hydraulic systems are used.

References

1.M Knights, “Electric, Hydraulic or Hybrid: What's the Right Injection Press for You?” Plastics Technology 53, (2007): 68–75.

2.Z Turke, “Electric or Hydraulic; A Comparison of Injection Molding Machines,” Medical Product Manufacturing News, May 2001.

3.C Lhota and H Wobbe, “Success Is a Question of Detail,” Kunststoffe International 9, (2008): 79–81.

4.W Leventon, “The Many Facets of Modern Molding,” Medical Device & Diagnostic Industry 27, no. 5 (2005): 84–90.

5.C Goldsberry, “Cleanroom Molding: Balancing Cost and Benefit,” Injection Molding Magazine, September 2002.

6.National Environmental Balancing Bureau, Procedural Standards for Certified Testing of Cleanrooms, 2nd ed., 1996.

Copyright ©2009 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like