Understanding Permanent Magnets in Biomagnetic Separation

October 18, 2013

Understanding how constituent magnetic fields affect the final position of retained magnet beads, particularly in high throughput screening (HTS) applications, is important when developing protocols for DNA synthesis or laboratory testing. Biomagnetic separation is a simple and effective tool because magnetic beads and the target biological entities are suspended in fluids which have low magnetic permeabilities and which therefore do not impede the applied magnetic field. In addition, the biological entities themselves have low susceptibilities and thus the intended actions of the magnetic beads are not hindered by any significant magnetic response from the biological entities themselves.

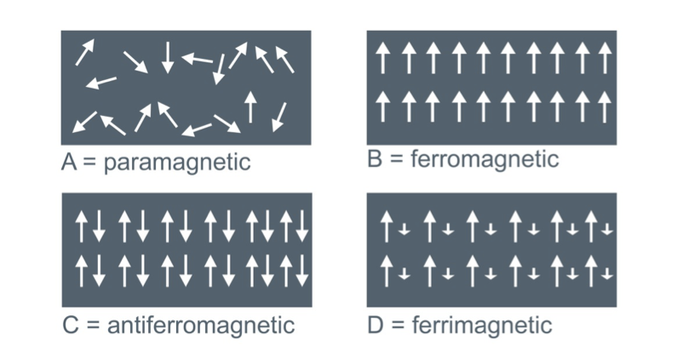

The reaction of different materials in separation depends on the existence and behavior of magnetic dipole moments within the material. Diamagnetic materials do not have magnetic dipole moments. The other material types do. Figure 1 is a schematic representation of the ordering of magnetic dipoles within the various magnetic materials.

|

Figure 1: Schematic classification of materials as a function of magnetic dipole ordering: A = paramagnetic, B = ferromagnetic, C = antiferromagnetic and D = ferrimagnetic. |

In order to cause the magnetic bead to move to a desired location within a container, it needs to experience a force that acts in the desired direction. This is accomplished by not only producing a significant magnetic field within the container, but also by designing the system such that there is a significant magnetic field gradient within it.

The applied force needs to overcome any friction or viscosity-related resistance caused by moving the bead within the fluid medium and it also needs to overcome any gravitational effects. While these additional effects (in particular the fluid viscosity) may not be insignificant, the force generated on the bead by the applied magnetic field is the dominant factor in such systems. When small volumes are being separated, for example in high throughput screening (HTS) protocols, these additional effects can be neglected without negating the basic principles.

Application of too much force on magnetic beads attached to biological entities can cause those entities to be damaged during the separation process and while the beads are retained at the container wall, possibly crushing or otherwise deforming delicate biological structures. Aside from causing the separation in the first place, there needs to be enough force acting on the beads once retained, so that the remaining fluid can be decanted effectively without losing any of the retained beads. A balance is required between these two factors and end users should investigate the effects of separator systems and the specific beads being used on the target entities to avoid this potential type of damage.

|

Biomagnetic separation devices. Image courtesy of Dexter Magnetic Technologies. |

The behavior of magnetic beads within biomagnetic separation systems can be carefully controlled by matching the needs of the protocol to the right beads and the right separator devices. Understanding the basics of magnetic principles helps to define requirements in specifying biomagnetic separator devices. A wide variety of separator designs allows the user to select an appropriate means of separation, based on fluid sample volume, required speed of processing and other parameters.

Further reading on biomagnetic separation techniques and permanent magnet separation products can be found online at DexterMag.com. A technical article (in PDF format) explaining this subject in more detail is also available.

Mike Devine is the application engineering manager at Dexter Magnetic Technologies, Inc. (Elk Grove Village, IL)

About the Author(s)

You May Also Like