3 Promising 3-D Printing Technologies to Watch

Don't write off 3-D printing as an overhyped technology just yet. Here are three 3-D printing applications that could actually reshape medical device manufacturing.

Brian Buntz and Chris Newmarker

|

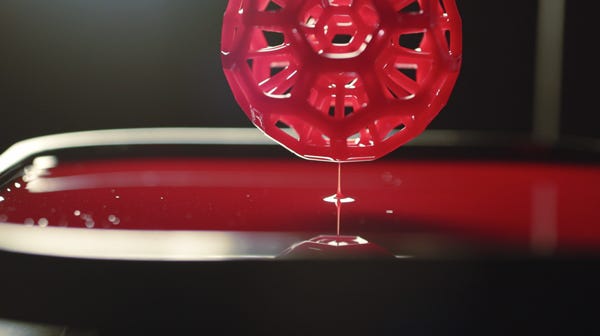

A company founded by UNC-Chapel Hill professors recently touted its new Terminator 2-inspired CLIP technology that promises printing speeds 25 to 100 times faster than the current crop of 3-D printers. (Image courtesy of Carbon3D Inc.) |

Influential science fiction author William Gibson wrote: "The future is already here--it's just not very evenly distributed." His words describe the current state of 3-D printing--while it is becoming an ever more common tool for prototyping, it's real potential hasn't been tapped yet by the medical device industry. But the groundwork has been laid for 3-D printing's big break.

Consider, for instance, a new technology called continuous liquid interface production (CLIP), which allows complex objects to emerge out of a pool of resin as though they were the T-1000 emerging from liquid metal in Terminator 2. Or how about University of Louisville professor Stuart Williams's boasts that it will be possible within our lifetimes to 3-D print complex organs. Already, the use of 3-D printing to make injection molds is allowing the technology to be used for some degree of production rather than mere prototyping.

Rob Richards, business development manager at Orchid Design (Shelton, CT), part of Orchid Orthopedic Solutions, ticks off a number of advantages that 3-D printing brings to medtech: customization and more-sophisticated designs that could overcome drawbacks associated with the present death of 3-D printing medtech materials.

The direct metal laser sintering machines that Ortho uses can be precise to within 0.0015 in., while molding or extrusion often has tolerances within 0.005 in., according to Richards. This means that 3-D printing is already winning out when it comes to precision.

"We're already more accurate than standard manufacturing tolerances," Richards says. "Speed is getting better. The cost is getting lower."

1. T2-Inspired 3-D Printing Technology

A company founded by UNC-Chapel Hill professors recently touted its new Terminator 2-inspired CLIP technology that promises printing speeds 25 to 100 times faster than the current crop of 3-D printers. Just picture a polymer object literally rising out of a pool of liquid media in minutes rather than the hours it would take for a traditional 3-D printer to lay down material.

The UNC-Chapel Hill researchers are now focused on bringing the technology to market through their Redwood City, CA-based startup Carbon3D Inc.

As for the technology's Terminator 2 inspiration, the CEO of the company, Joseph M. DeSimone, PhD, explains that he was inspired by the way the next generation T-1000 robot assassin rises out of a puddle of material in that film, as he explained during a recent TED talk. "We thought, 'Why couldn't a 3-D printer operate in this fashion, where you have an object arise out of a puddle in essentially real time with essentially no waste to make a great object,'" said DeSimone--who is also a professor of chemistry at UNC-Chapel Hill and of chemical engineering at NC State.

Refresh your medical device industry and 3-D printingknowledge at BIOMEDevice Boston, May 6-7, 2015, or MD&M East in New York City, June 9-11, 2015. |

With $51 million in venture capital funding behind them, they're already touting the technology's potential in the medical device and drug-delivery industries.

"Since CLIP facilitates 3-D polymeric object fabrication in a matter of minutes instead of hours or days, it would not be impossible within coming years to enable personalized coronary stents, dental implants or prosthetics to be 3-D printed on-demand in a medical setting," DeSimone said in a UNC-Chapel Hill news release.

The CLIP technology works by carefully balancing the interaction of ultraviolet light, which triggers photo polymerization, and oxygen, which inhibits the reaction. In the process, an object can be 'grown' out of a pool of resin. Carbon3D explains on its website that the key to this process is a special window that is transparent to light and permeable to oxygen, much like a contact lens.

The company goes on to explain: "By controlling the oxygen flux through the window, CLIP creates a 'dead zone' in the resin pool just tens of microns thick where photopolymerization cannot occur. As a series of cross-sectional images of a 3-D model is played like a movie into the resin pool from underneath, the physical object emerges continuously from just above the dead zone."

Carbon3D claims that CLIP can produce a 51 mm-diameter complex object in 6.5 minutes, versus three to 12 hours with traditional 3-D printing. DeSimone envisions that the technology could eventually 3-D print objects 1000 times faster than what is presently possible as the ability to deliver liquid improves. He also looks forward to the time when the machines will need to be water-cooled because they are going so fast.

Objects produced can have feature sizes below 20 µm, or less than one quarter of the width of a piece of paper. Plus, CLIP-made objects are more like injection-molded parts in that they have consistent and predictable mechanical properties: They are smooth on the outside and solid on the inside, according to the company.

In addition, a wider range of materials can be used in the process, including elastomers, silicones, nylon-like materials, ceramics, and biodegradable materials, UNC-Chapel Hill reported. "We're able to throw the entire polymer chemistry textbook at this. We're able to design chemistries that give rise to properties you really want in a 3-D printed object," DeSimone remarked in his TED talk.

"When we met Joe and saw what his team had invented, it was immediately clear to us that 3-D printing would never be the same," stated Jim Goetz, a Carbon3D board member and partner at one of its backers, Sequoia Capital.

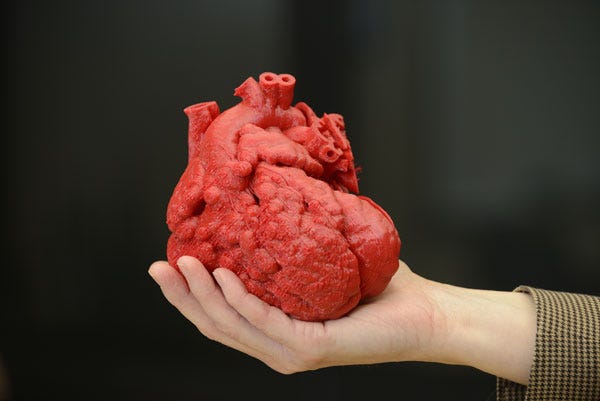

2. A 3-D Printed Human Heart?

|

"I believe the heart is going to be one of the easiest organs to print because it has very few types of cells and a relatively simple function--it just has to have a contractile capability," says University of Louisville professor Stuart Williams. |

"We've been using medical devices for decades in order to keep our tissues and organs going until we figure out a way of reconstructing those tissues and organs," University of Louisville professor Stuart Williams said at the Bay Area Biomedical Device Conference, held March 31 at San Jose State University. "Medical devices hopefully will just be bridges to biological solutions."

Having 3-D printed complex organs might be a reality in our lifetimes. In fact, Williams has the goal of creating a 3-D printed heart within a decade's time. "I believe the heart is going to be one of the easiest organs to print because it has very few types of cells and a relatively simple function--it just has to have a contractile capability," he said.

"The brain would be the most difficult organ to print because we will argue over 1000 years whose brain to use as a model," he joked. Organs such as the liver and kidney would also be challenging to print, falling somewhere in the middle of the heart and brain. "We can print hundreds of thousands of cells and create the form of a kidney but we don't know how long it will take to create a functional kidney," he explained. "That's why I want to go after the heart first. It is relatively simple and one of the easiest organs to transplant."

He's not alone. Researchers at Wake Forest University (Winston-Salem, NC) also have the goal of 3-D printing whole organs.

And the San Diego-based firm Organovo was cofounded by Gabor Forgacs, who initially envisioned printing of whole organs, when the company was founded in 2007. The company is already printing functional living models of human livers.

While the idea of tissue engineering, or at least culturing organs, actually goes back to the work of Charles Lindbergh in the 1930s, we are just now on the verge of using stem cells to repair an array of health problems. "We are not quite there yet," Williams acknowledged, but research breakthroughs are being announced on a near daily basis, and clinical trials are being launched across the world to evaluate tissue regeneration.

"The hope is that stem cells will become everything that we possibly need as a replacement. We are going after absolutely everything. We want to take medical devices out of it and repair all of these tissues," Williams added.

To support this argument, Williams points to how far tissue engineering has already come. A company named Tissue Genesis (Honolulu) has developed technology that can isolate tens of millions of regenerative stem cells in an operating room environment in an hour's time. In 2011, the company launched a clinical trial to test a stem-cell-coated vascular graft.

A year prior to that, the Economist ran a cartoon suggesting that 3-D printers could print out any organ a surgeon might need. "We are getting pretty close to that as these devices are starting to move into the operating room," Williams notes.

Right now, 3-D printing has reached the stage of clinical use for certain applications, such as the production of custom anatomically correct heart models or vascular systems that are used by surgeons as a training aid.

While printing a functional heart may sound like science fiction today, Williams remarks that perhaps even Star Trek doesn't boldly go where it should. "In a few hundred years, Jean-Luc Picard [in Star Trek: Next Generation] still gets a piece of plastic and metal to fix his heart. For God's sake, go and talk to your science fiction writers and tell them there is hope in regenerative medicine and cell-based therapy for the heart, too."

The biggest hurdle that still remains for the field is related to bioinks. "We are getting good at the isolation of cells, processing images, bioprinting, using glues and polymers--extracellular matrix and other materials--we understand additives, are getting much better at understanding growth factors. But putting them all together into a bioink and being able to print a structure that then develops to a kidney, a heart, a brain, or whatever it is, that's where the real problems exist," Williams said.

While it is already possible to create detailed models of the heart based on MRI or CT data, Williams recommends not holding too closely to the organ's original design. "The original design for a heart is flawed because it puts one major vessel into the left part of the heart. As we talk about printing a new heart, why don't we make a better design?"

Already, scientists can print vascularized tissue, making it possible to create heart valves and cardiac patches that can be surgically implanted and become fully functional within a short period of time. "Cells from fat can be used to grow brand new blood vessels. We also find you can do that under in vivo conditions,"Williams says.

3. 3-D Printing + Injection

Molding

It may not be as mind-blowing as something out of Terminator 2 or growing organs. But a significant shift in medtech manufacturing is already underway when it comes to using 3-D printing to create injection molds that are then used to produce larger quantities of parts.

About five years ago, Nadav Sella, now director, manufacturing tools at Stratasys (Eden Prairie, MN), spotted a company using 3-D printing to make injection molds. "I was very enthusiastic about the process and I started working to develop the technology," Sella says, who at that time was working at Objet.

Fast forward to the present, and Stratasys now has dozens of customers across a range of industries employing the process, mainly using thermoplastics and thermoplastic elastomers but also engineering plastics. "Basically, we are seeing more and more interest in 3-D printing of injection molds," Sella says.

While the technique cannot completely replace traditional steel and aluminum molds for all applications, it is well suited for producing the first run of injection molded parts. The technique also can be used for short production runs of parts from the end product material. "It can be very helpful when you want to get your product into regulatory, sterilization, or functional tests," Sella explains.

Using standard plastics, the technique can be used to produce 50 to 100 parts. Using engineering plastics at up to 300 °C, 5 to 40 parts can be produced. Finally, with TPE, more than 100 parts can be made.

A type of rapid prototyping known as casting is similar. Basically, it involves printing the molds and then casting metal parts in them. This technique offers similar advantages to 3-D printing injection molds: It is much quicker and less expensive than traditional methods of creating metal casting molds.

Still, Rob Richards of Orchid Design acknowledges that there are drawbacks with the technique, especially when a part needs secondary manufacturing. Parts produced through such a process are not purely homogeneous, which makes it technically challenging to then run them through electronic discharge machining.

When used for plastics, two of the primary advantages of this 3-D printing application are cost and time savings. "If you could use the technique in the design process to make one mold per week and save $2000 per tool, that translates to a savings of more than $100,000 per year," Richards says. "The more complex the mold, the more significant the cost savings."

The design firm Worrell Design (Minneapolis; www.worrell.com), which is collaborating with Stratasys on 3-D printed injection molds, says the technique usually costs 70% less than traditional tooling production.

Another advantage for medical device companies is that it can be used to reduce the time to market. Worrell estimates that it takes approximately 96% less time than traditional tooling when used for small-batch prototyping. Instead of taking six to eight weeks to produce tooling, it can be accomplished in a matter of days.

Worrell has already used 3-D printing to create a prototype for a novel emerging care device. The company used the prototype to perform validation and functionality testing, which helped lead to helpful design iterations sooner than it would have otherwise, the company says.

Diversified Plastics, a custom plastic injection molding company also based in Minneapolis, is also leveraging 3-D printing to make injection molds. After acquiring a Objet 260 Connex 3-D printer in 2014, the company used the system to print molds for a medical device client that had tight time-to-market requirements.

Stratasys has developed a material known as Digital ABS that combines high-temperature resistance and toughness that is well suited for the process. The material is heat-resistant and strong enough to stand up to short injection molding runs in the range of 10 to 100 parts.

"Digital ABS is a thermoset acrylic material that can be cured with UV light," Sella explains. "It is made out of two base components that are printed simultaneously." Digital ABS's name is a reference to the polarity of its ingredients: one of the materials used in the material features high heat resistance while the other offers toughness. "We can precisely control how the droplets of the two materials are 3-D printed. We can put them side by side and control each drop."

Refresh your medical device industry and 3-D printingknowledge at BIOMEDevice Boston, May 6-7, 2015, or MD&M East in New York City, June 9-11, 2015. |

Brian Buntz is the editor-in-chief of MPMN and Qmed. Follow him on Twitter at @brian_buntz.Chris Newmarker is senior editor of MPMN and Qmed. Follow him on Twitter at @newmarker

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like