3-D Printer Hack Can Detect Infectious Diseases

July 28, 2016

Using repurposed 3-D printer parts, researchers were able to prep samples and amplify DNA at a fraction of the cost associated with traditional equipment.

Kristopher Sturgis

The latest in 3-D printing technology aims to enable researchers to perform sample preparation and DNA amplification--all done with repurposed 3-D printing components for a fraction of the cost.

The new technology was created at AI Biosciences Inc. where Season Wong, company CEO and cofounder, realized that 3-D printers already have the components needed to perform automated nucleic acid extraction and DNA amplification. He discovered that using repurposed 3-D printer parts could provide healthcare facilities with these tools at a much cheaper price than traditional sample preparation instruments, which can cost up to $15,000 per unit.

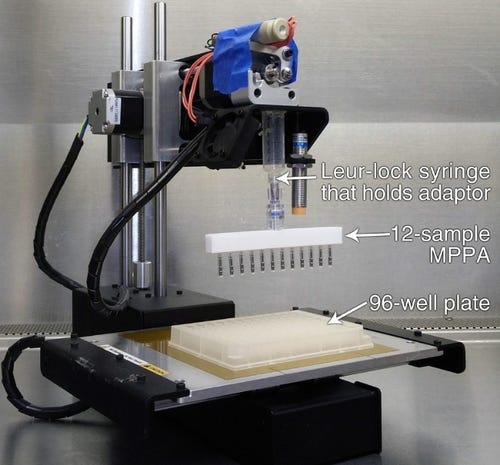

Given that essentially all diagnostic protocols require sample preparation, many clinics in resource-limited areas are unable to perform basic sample preparation and DNA amplification for various diagnostic processes. Wong and his colleagues began working with entry-level 3-D printing devices that typically run for less than $1000 and convert the printer's extruder with a 3-D printed magnetic particle processing attachment designed by the company.

This attachment enables the printer to hold a disposable tip comb, where custom programs can be used to mimic the actions of a sample preparation device. So far, the group has been able to successfully process up to 12 samples simultaneously in less than 13 minutes for nucleic acid extraction. They've even been able to demonstrate that the DNA extraction efficiency using 3-D printer components is on par with the gold-standard spin-column method.

3-D printing technologies are certainly on the rise as the market is projected to grow 40% annually over the next five years, according to the investment firm Ark Invest (New York City). The 3-D printing industry is currently a $5.5 billion dollar industry, and could soar to as much as $40 billion by 2020. When it comes to medtech, 3-D printing techniques are expected to have a significant impact on the next generation of medical device manufacturing -- an indicator of just how far the technology can reach.

These trends are a big reason why Wong and his colleagues believe that their technology could be so revolutionary. 3-D printing technologies will become more ubiquitous as the manufacturers continues to evolve and advance printing techniques. As more people gain access to 3-D printing technologies, this group believes that developing a process that can adapt the components of virtually any 3-D printer could be a real boon for healthcare facilities with limited resources.

To showcase this, Wong and his colleagues packed two basic 3-D printers in regular luggage and transported them to Johns Hopkins University in Maryland where they could be used to demonstrate extraction and PCR amplification of Chlamydia trachomatis DNA from urine samples. Their recent paper describing the work shows that both DNA and RNA based extraction is feasible with their technology using a converted low-cost 3-D printer.

As they move forward with their research, Wong and his colleagues plan to use the technology to demonstrate the rapid detection for other infectious diseases, as well as evolve the technology so that it can be used to advance STEM education in schools. The group was also quick to note that its printer conversion is completely reversible, so it does not mean these devices will lose their printing functionality. The aim was to provide anyone with 3-D printing technologies to implement their approach without the need for other, much more costly instruments.

About the Author(s)

You May Also Like