In this fast-paced environment, there is a real need for partners who can expedite the launch of highly-complex, critical parts while holding a firm commitment to the quality and standards. Contract manufacturers can adapt these philosophies to understand how to help customers turn vital deadlines into finish lines.

September 25, 2017

Facing fierce market competition and increasingly rapid technological change, medical device manufacturers are under constant pressure to innovate—and quickly. Companies face long, expensive product development cycles involving many stakeholders, internal reviews, design updates, validations, regulatory approvals, and more. During these product development cycles, timelines often shift—but critical deadlines do not.

In this fast-paced environment, there is a real need for partners who can expedite the launch of highly-complex, critical parts while holding a firm commitment to the quality and standards needed in Class II and Class III devices. Contract manufacturers can adapt the following philosophies to understand how to help customers turn vital deadlines into finish lines.

Work Smarter, Not Harder

When facing the need to get to market quickly, it’s easy to look for the quickest fix to a problem. However, absent a well-thought-out process, manufacturers can often experience a “doom loop” of development. One decision that does not address the root cause can lead to a vicious cycle of continued delays and increased project costs.

The best way to avoid the doom loop is through an investment in the right process to allow for smarter—not harder—work. Doing so will create a more efficient program that gets products to market on time. Two things are critical to doing this successfully.

First, solving complex manufacturing problems isn’t easy. Make sure you’re working with companies who will value and invest in your project and bring together the right team that complements the experience and expertise you bring to the table.

Second, get it right the first time by making a big enough investment in upfront engineering. This investment will allow your team to uncover the right combination of capabilities, methodologies, materials, and more to drive toward an overall smarter process. It will also set you up to troubleshoot potential delays before they happen.

Ultimately, the right process drives the right solution. Defining the process upfront will help your team succeed in reaching critical launch dates and customer goals. And, it often provides manufacturing solutions to business problems your customers have been struggling to solve.

Bring Better Expertise and Better Solutions

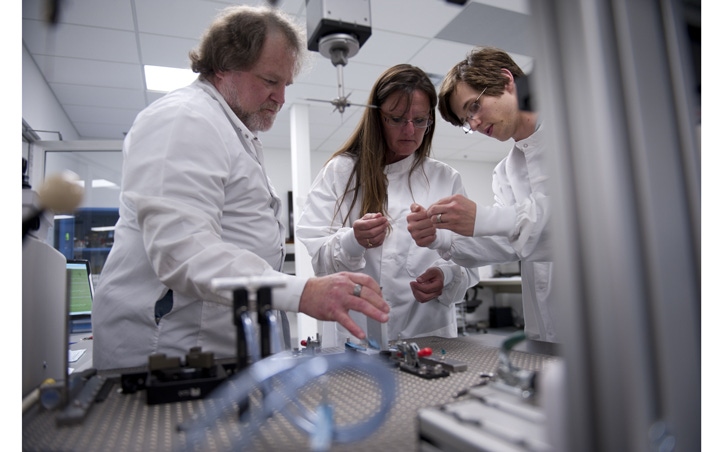

Manufacturing problems often don’t have an easy answer. But, with a full range of capabilities under one roof you can break down the silos. When bringing together internal design and mold building, injection molding, machining, and secondary operations, you can streamline processes, troubleshoot, and creatively solve problems to produce better—and faster—results. This also allows you to build a team with different backgrounds and unique experience to help uncover new solutions that drive higher quality, reduced costs, and increased speed to market.

Bringing together individuals with unique competencies and perspectives allows you to pass on increased innovation to your customers by:

Streamlining the supply chain by keeping your capabilities in house and eliminating additional cost and time dedicated to working with multiple suppliers with multiple opinions.

Creating smarter solutions through creative collaboration and the application of different skillsets to programs—like designing an innovative injection molding process to eliminate complex and inefficient assembly operations—to pass on resource efficiencies to the customer.

Empowering all team members to have a seat at the table, encouraging individuals to speak up and contribute to the solutions that reduce costs, speed timelines, and provide enhanced quality.

The ability to get to market quickly lies in understanding how to bring together the right team to take control of the manufacturing process and drive toward the best outcome. Doing so is critical in demonstrating your ability to succeed with complex programs.

Build Lasting Trust

With any successful project focused on speed-to-market improvements, the core of the program is the ability to build credibility and trust with customers. Trust cannot be bought. It’s earned over time. By proving yourself as a problem solver and trusted resource, you can build the valuable relationships critical to sustained success.

Consistently hitting aggressive deadlines lays the foundation for a trusting, lasting relationship. These four areas of focus will help you continue to hit these deadlines in a way that proactively builds trust with customers.

Drive accountability for everyone on your team. Make sure people are clear on their roles and responsibilities, and are committed to driving value in everything they do.

Bring teams together to leverage individual expertise and drive overall program and process understanding.

Drive efficiencies throughout the process. Eliminate unnecessary steps. Streamline the process and always look for ways to save time and cost.

Expedite processes and minimize risk. Leverage vertical integration and fully utilize resources to maximize efficiency through standard process executions.

Ultimately, when it comes to getting to market quickly, it’s not just about faster machines and reduced cycle times. It’s about building the right team, creating the right processes, and establishing the right measures of success.

Rapidly Reaching Your Deadlines

When looking at how to face mounting competition and rising pressure in the medical device market, manufacturers must understand the steps needed to drive toward consistently faster outcomes.

It starts with the right process, and is built upon the ability to forge partnerships with your customers based upon mutual trust, respect, and commitment to a shared goal. Together, working through upfront engineering and integrated teams, you will be able to address what’s behind the manufacturing issues to truly turn your customer deadlines into finish lines.

About the Author(s)

You May Also Like