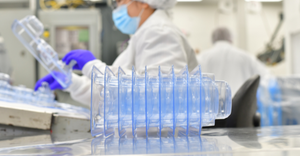

Packaging

Sanguina AnemoCheck Home at-home anemia test

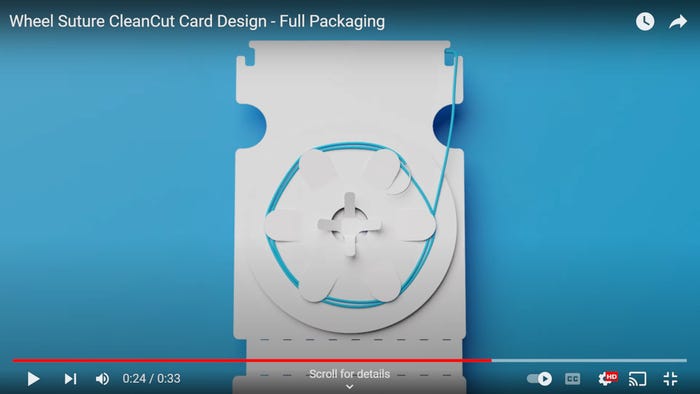

Packaging

Medical Test Kits Find a New HomeMedical Test Kits Find a New Home

Patients appreciate the comfort, convenience, and confidentiality of testing and treating themselves where they live.

Sign up for the QMED & MD+DI Daily newsletter.

.png?width=300&auto=webp&quality=80&disable=upscale)