November 9, 2011

Leak-Testing Equipment Design Services The Leak Detector Express Proposal service featuring guaranteed rapid reply to requests for proposals and the Leak Detection Equipment Custom Application Proposal service for unusual and complex applications are available to medical device manufacturers from Uson LP, a supplier of dry-air leak detection systems. In the first case, the service provider's leak-testing applications laboratory can determine which of the company's late-model leak testers is the best match for the customer's quality assurance requirement. In the second, the company can provide a leak-testing solution customized to meet more-challenging test specifications. Both levels of service are designed to find the best-match leak tester among the manufacturer's various models. Newer models provide data storage capabilities that support Six Sigma and similar modern quality initiatives.

The Leak Detector Express Proposal service featuring guaranteed rapid reply to requests for proposals and the Leak Detection Equipment Custom Application Proposal service for unusual and complex applications are available to medical device manufacturers from Uson LP, a supplier of dry-air leak detection systems. In the first case, the service provider's leak-testing applications laboratory can determine which of the company's late-model leak testers is the best match for the customer's quality assurance requirement. In the second, the company can provide a leak-testing solution customized to meet more-challenging test specifications. Both levels of service are designed to find the best-match leak tester among the manufacturer's various models. Newer models provide data storage capabilities that support Six Sigma and similar modern quality initiatives.

Uson LP

HOUSTON

www.uson.com

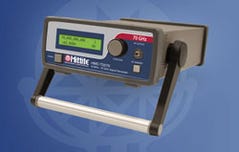

Signal Generator Suitable for medical device applications, the HMC-T2270 synthesized signal generator for engineering development and production test environments is designed to deliver a clean signal, broad frequency coverage, and high output power for its class. Sweeping from 10 MHz to 70 GHz, the generator, available from Hittite Microwave Corp., delivers up to

Suitable for medical device applications, the HMC-T2270 synthesized signal generator for engineering development and production test environments is designed to deliver a clean signal, broad frequency coverage, and high output power for its class. Sweeping from 10 MHz to 70 GHz, the generator, available from Hittite Microwave Corp., delivers up to

29 dBm of continuous-wave output power in 0.1-dB steps over a 60-dB dynamic range. Harmonic rejection is better than -40 dBc at 30-GHz output. Phase noise is -113 dBc/Hz at 10 kHz offset from 1 GHz and

-79 dBc/Hz at 100 kHz offset from 67 GHz. Deviation over the temperature range of 0° to 35°C is insignificant. The generator's frequency resolution of 1 Hz and fast switching speed of 500 microseconds make the device suitable for frequency-hopping applications. The generator is compatible with many different control interfaces to facilitate integration in test environments.

Hittite Microwave Corp.

CHELMSFORD, MA

www.hittite.com

Balloon Visual Inspection System Upgrades to Interface Catheter Solutions' balloon visual inspection system have resulted in reduced cycle times. Used in both quality manufacturing inspection and R&D, the system provides visual inspection and dimensional measurements of medical balloons in a single operation, adding consistency and accountability to the inspection process. Inspection operations include classification and size of defects with pass/fail analysis based on user-selected criteria. Relying on a vision system and analysis program featuring an intuitive user interface, the system provides immediate detailed visual and data reporting. It also features enhanced pneumatic rotary air chucks for quick and easy loading and unloading of balloons and a tight, reliable seal. Additional upgrades include higher pressure capability for pressures up to 13 atmospheres, improved pressure accuracy, and a new digital pressure output gauge that provides improved pressure-accuracy reliability.

Upgrades to Interface Catheter Solutions' balloon visual inspection system have resulted in reduced cycle times. Used in both quality manufacturing inspection and R&D, the system provides visual inspection and dimensional measurements of medical balloons in a single operation, adding consistency and accountability to the inspection process. Inspection operations include classification and size of defects with pass/fail analysis based on user-selected criteria. Relying on a vision system and analysis program featuring an intuitive user interface, the system provides immediate detailed visual and data reporting. It also features enhanced pneumatic rotary air chucks for quick and easy loading and unloading of balloons and a tight, reliable seal. Additional upgrades include higher pressure capability for pressures up to 13 atmospheres, improved pressure accuracy, and a new digital pressure output gauge that provides improved pressure-accuracy reliability.

Interface Catheter Solutions

LAGUNA NIGUEL, CA

www.interfaceusa.com

About the Author(s)

You May Also Like