February 29, 2012

|

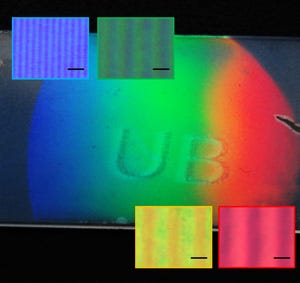

A rainbow-colored grating, about 25 millimeters wide, under sunlight. Enlarged microscope images show the graded surface, with the black bars indicating a length of 10 microns. Image: University of Buffalo |

University at Buffalo (UB) reports that engineers at the school have developed a one-step, low-cost method for fabricating a polymer that, when viewed from a single perspective, is rainbow-colored, reflecting many wavelengths of light. Used as a light filter, this material could form the basis of handheld multispectral imaging devices that identify the "true color" of objects examined.

Such portable technology could have applications in biomedical imaging, including analyzing colors in medical images to detect disease, according to UB vice president for research and economic development Alexander N. Cartwright, one of the researchers who led the study.

The ease of producing the polymer could make it feasible to develop small devices that connect with cell phones to conduct multispectral imaging, said Qiaoqiang Gan, a UB assistant professor of electrical engineering and another member of the research team.

"Our method is pretty low-cost, and because of this and the potential cell phone applications, we feel there is a huge market for improving clinical imaging in developing countries," Gan said.

To create the rainbow material, Liu and Xu sandwiched a photosensitive pre-polymer syrup between two glass slides. Next, they directed a laser beam through a curved lens placed above the pre-polymer solution. The lens divided and bent the laser beam into light of continuously varying wavelengths.

As this light hit the solution, monomers in the solution began joining into polymers, forming a continuous pattern of ridge-like polymer structures. Larger ridges rose where the light struck with more intensity.

The resulting structure is a thin filter that is rainbow-colored when viewed under white light. This is because the periodic polymer layers reflect a continuous spectrum of colors, from red on one end to indigo on the other.

The single-step fabrication method -- shining a laser light through a curved lens -- is affordable and relatively simple. The UB Office of Science, Technology Transfer and Economic Outreach has submitted a provisional patent application detailing the production process.

The filter the researchers created was about 25 millimeters long, but the technique they used is scalable: It is possible to create filters of different sizes by shining the laser through lenses of different sizes.

Gan said the next step for the researchers is to improve the quality of the rainbow filter. The team is also beginning to explore ideas for incorporating the technology into handheld devices.

Cartwright and Gan's team's polymer fabrication technique was published online last week in the journal Advanced Materials. Coauthors of the study include UB students Ke Liu and Huina Xu and UB research scientist Haifeng Hu.

About the Author(s)

You May Also Like