March 10, 2010

trac-taper-measurement-system

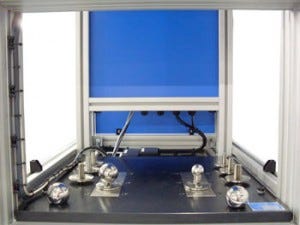

The Mechanical Taper Gauge from Trac Measurement Systems achieves a 6-sec cycle time and 1-µm accuracy.

To ensure that tapers on orthopedic implants have tolerances as low as 10 µm, Trac Measurement Systems Ltd. (Telford, Shropshire, UK) has developed a new taper-measurement gauge that outperforms current systems, according to the company.While coordinate-measuring machines (CMMs) and air gauges are traditionally used to verify taper dimensions, both methods have drawbacks. For example, CMMs are slow and expensive, while air gauges are fast but carry a high cost of ownership because they require many masters. In addition, air gauges lack flexibility, Trac says.In addition to offering a 6-sec floor-to-floor cycle time for a 30-mm taper, Trac's Mechanical Taper Gauge ensures 1-µm accuracy. Based on analog scanning, the system provides large quantities of data and ensures outputting straightness.

You May Also Like