Organovo has created functional tissue using a 3-D bioprinter that executives believe will transform medical research, drug discovery and ultimately clinical therapies.

July 19, 2013

Science, especially medical science because of its potential to improve the human condition, can be wondrous.

Straddling the line between almost incomprehensibly amazing and can-this-indeed-be-possible is San Diego-based 3-D bioprinting company Organovo.

3-D printing by itself is quite extraordinary and is having a growing impact on the practice of medicine. But 3-D bioprinting, in the way Organovo has envisioned it, has the potential to remake the world of regenerative medicine and drug discovery. And possibly redefine what a medical device is.

Exactly, how does it work?

Organovo uses bioink made up of various human cells and places them in a precise manner using its NovoGen MMX Bioprinter into microplates or other form factors. Because these cells are placed in a certain architecture and are fed nutrients, they begin to signal each other and begin to behave naturally, catalyzing the formation of tissue. Here’s how Organovo’s Michael Renard, Executive Vice President of Commercial Operations, describes the process:

The fundamental theory of what we've put into practice is if you take your sources of cells, you compare those cells in a very specific way and those cells are precisely deposited with the use of a precision instrument which is in our case a 3-d bioprinted process we can deposit those cells in 3d. Those cells, given that circumstance, will then signal each other and formal a final tissue and this is all being done as a function of the inherent developmental biology that these cells are programmed by.

In other words, Organovo is creating functional human tissue in 3-D form harnessing not only its expertise in tissue engineering and biology but also by allowing nature to take over once it is finished manipulating the cells and placing them in a certain microenvironment.

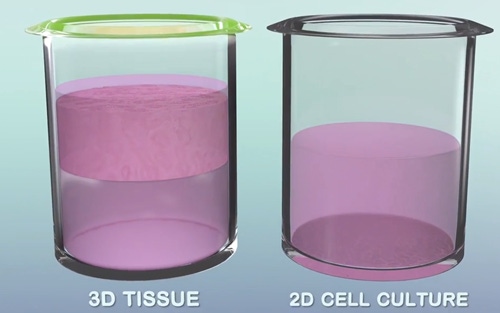

What you end up with is functional human tissue instead of 2-D cell cultures that have become so ubiquitous in medical research and testing.

This has naturally piqued the interest of pharma companies forever looking for ways to develop safe and effective drugs quickly with robust test models.

“The cells are performing in their native way and that's what intrigues drug companies,” Renard says. “The fundamental difference and where I say that we are working in a very unique and distinguished space is we are taking cells, we are using those cells to make fully functional human tissue without any artificial or biomaterials in the final product. So what you have at the end of our process is a solid piece of tissue. It's not a droplet with cells floating around.”

Earlier this year, Organovo published data on its 3-D bioprinted liver model and found that the liver tissue lasts much longer than 2-D cell cultures. But perhaps more worthy of celebration is the fact that the tissue began to function like normal liver tissue – it began producing liver-specific proteins such as albumin and transferrin, as well as the biosynthesis of cholesterol.

Even before the data was published, Organovo struck agreements with Pfizer and United Therapeutics to use its technology for drug discovery. In January, the company signed another agreement, this time with the Knight Cancer Institute at Oregon Health & Science University to develop more clinically predictive in vitro 3-D cancer models to advance discovery of novel cancer therapeutics.

But working with large drug firms and medical research groups to do custom models is only one leg of the company’s three-pronged business model. Organovo plans to launch a line of off-the-shelf functional tissue for research and drug pathology purposes. That will begin with a 3-D bioprinted liver tissue expected to launch in 2014, Renard says.

And the third goal – for which it has to obtain FDA approval - is to launch tissue-engineered therapies. In other word, create functional tissue that can be implanted or delivered into the human body to repair or replace damaged or diseased tissue.

As it makes progress in the scientific field, Organovo has also made strides in the business world. In February 2012, it went public on the over-the-counter market through a reverse merging raising more than $15 million. On July 12, the company’s stock moved to the NYSE MKT, an exchange intended for small, growth companies. Last year, it moved to a larger lab in San Diego. Last year it had revenue of $1.2 million, up from $969 million. The company is not profitable and won’t be for some time.

So when can we see 3-D bioprinted human organs? Not any time soon says Renard although that is possible one day. But if you are looking for an exact physical replica of a human organ, you’d be better off watching a science fiction movie – or wait for regenerative medicine companies like Miromatrix that use decellularized matrixes as a base for creating tissue and one day organs to fulfill their promise.

“When you think of growing tissues for therapies, you can think of some simple therapies such as cardiac muscle that can be used in a damaged heart to repair itself,” Renard says. “I encourage you not to think of building a kidney that anatomically looks like the human kidney as what’s in our future. What I would encourage everyone to think is what’s the functional piece of tissue would return function to that patient.”

Here's a an animation of how the 3-D bioprinting process works.

You May Also Like