May 1, 1998

X-y-z dispensing systems

A line of x-y-z systems are designed for automatic placement of adhesives in medical device manufacturing applications. Many different types of adhesives can be used, including UV adhesives, epoxies, solvents, super glues, and RTVs. The manufacturer offers both stepper-controlled, belt-driven systems for point-to-point dispensing with repeatabilities of 0.0002 in. or servomotor-driven systems with precision-ground leadscrews that are capable of making arcs, circles, and complex movements with a repeatability of ±0.0008 in. The system software is capable of up to 2000 commands with a recall of as many as 512 programmed coordinates. Glenmarc Manufacturing Inc., 25661 Hillview Ct., Mundelein, IL 60060.

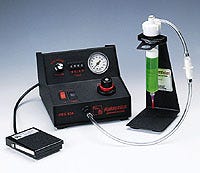

Adhesive dispensing system

A pneumatically operated dispensing system provides precise control for dispensing low-, medium-, and high-viscosity anaerobic, cyanoacrylate, and light-curing adhesives typically used in the assembly of metal, rubber, and plastic device subcomponents. The Bond-A-Matic 3000 eliminates the need for small-container premiums, reducing adhesive costs by as much as 50%. The unit's handheld Vari-Drop applicator valve enables the operator to control the amount of adhesive dispensed. Loctite Corp., 1001 Trout Brook Crossing, Rocky Hill, CT 06067.

Solvent dispensers

Solvent dispensers for use in medical device manufacturing are designed for bonding PVC, ABS, and other polymer components. The dispensers are available in three different configurations with one, two, or four dispensing bushes. Once the tubing or component is inserted into the bush, it is instantly ready for bonding. The dispensing bushes are custom made so that solvents can be dispensed on external or internal tubing surfaces, soft and rigid drip chambers, needles, conical surfaces, and various types of connectors and components. The solvent dispensers are manufactured with materials that are resistant to the most common solvents employed to assemble medical products, such as cyclohexanone, methylethylketone, dichloroethane, and tetrahydrofuran. All solvents or mixtures must be pure and particle-free. Technomed Inc., 68 Stiles Rd., Salem, NH 03079.

Pump for dispensing

A line of precision pumps integrates valveless piston technology with precision stepper motor control. The Model STQ pump features one moving part—a ceramic piston that rotates and reciprocates within a precision ceramic liner—and an inert fluid path of ceramic and fluorocarbon. The pump dispenses at a rate of 0.0021.28 ml/stroke with greater than 1% accuracy. Fluid Metering Inc., 5 Aerial Way, Ste. 500, Syosset, NY 11791.

Dispensing systems

A variety of dispensing systems are offered for use in medical equipment manufacturing processes. Dispensed materials can include adhesives, soldering masks, RTVs, silicones, soldering paste, and more. The Model KDS834A-D can be adapted to accept materials directly or via prefilled syringes. Syringe sizes include 3, 5, 10, and 30 cm3. Kahnetics Dispensing Systems, 2260 S. Vista Ave., Bloomington, CA 92316.

Reel-to-reel dispenser

A reel-to-reel dispensing system has the ability to handle delicate membranes and filter materials. The Matrix 6100 easily supports most liquid-related processes required for lateral-flow test strip development and manufacturing. Its high-efficiency dryer allows for accelerated web speeds when running in either the discrete striping mode or the wide-angle spraying mode, or in the dipping configuration. Quick-change modules enable production changeover from one process to the next in a simple, repeatable manner. Kinematic Automation, P.O. Box 69, Twain Harte, CA 95383.

Solvent dispensing system

A dispensing system provides neat and controlled application of solvents, cyanoacrylates, and other thin, watery assembly fluids. A 0–15-psi pressure regulator and microprocessor-based timer allow thin fluids to be applied in consistent amounts. By combining accurate timed-pulse dispensing with precision components specifically designed for use with low-viscosity fluids, the benchtop 1500XL-15 dispenser ensures reliable bonds and reduces cosmetic rejects. Fluid is loaded into a handheld barrel reservoir, into which an LV barrier is inserted to improve fluid control and contain fumes. Dispense tips feature clog-resistant Teflon liners and a precision crimp that help restrict the flow of very thin fluids. EFD Inc., 977 Waterman Ave., East Providence, RI 02914.

Single-component dispenser

A lightweight single-component dispenser provides cost-effective dispensing of thick liquids, greases, or pastes. Designed for trouble-free point-of-use dispensing, the SC dispenser can accept a number of 30–35-ml barrels or syringes. The lightweight design is manufactured from a durable plastic with a good mechanical advantage. The unit is well suited for adhesives and glues. TAH Industries Inc., 107 N. Gold Dr., Robbinsville, NJ 08691.

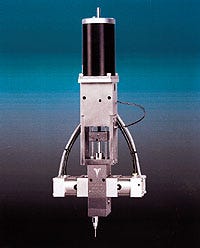

Robotic dispenser

A stand-alone robotic dispenser features a programmable z-axis with three independently controlled dispensing heads, making it suitable for dispensing multiple liquids or pastes in one production process. Each head of the Challenger 3H is mounted on a microadjustable slide for quick setup and easy adjustment. Materials of various consistencies from water to thick paste can be used. The robot includes brushless programmable motors, preloaded leadscrews, and ball slides for tight machine tool performance. The unit can be constructed from stainless steel, hardcoat aluminum, or polycarbonate. A pressure pot slides up on precision guides, enabling easy access to containers when loading and unloading. Online Inc., 3980 Albany St., McHenry, IL 60050.

Dispensing pen

A lightweight dispensing pen designed for manual operations facilitates dispensing of low- to medium-viscosity materials. Materials such as solder mask, liquid flux, oil, or paint are fed to the JC1015 pen from a reservoir or cartridge. Material flow is easily controlled by the pressure regulator found on most reservoirs. Featuring an instant finger-controlled shutoff function that accommodates dot, bead, gasketing, and potting applications, the pen can accept a variety of tips. I & J Fisnar Inc., 2-07 Banta Pl., Fair Lawn, NJ 07410.

Positive-displacement valves

Metering rod positive-displacement valves offer precise, programmable dot-to-dot or bead dispensing consistency. The Model 1053 valves, designed for servo or step motor drives, accurately dispense beads or dots ranging from 0.002 to 3.6 cm3. Virtually any single-component material can be used, including sealants, lubricants, acrylics, urethanes, epoxies, UV curables, and silicones, in a variety of consistencies. The valves are adaptable to single- or multiple-needle dispense blocks as well as workstations and automated equipment. LCC/Dispensit, 6896 Hillsdale Ct., Indianapolis, IN 46250.

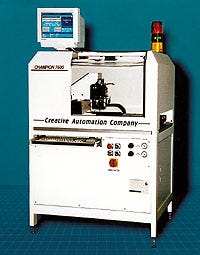

In-line automatic dispenser

A multipurpose in-line fluid dispensing system can handle virtually any conveyorized production application with ease. Featuring a noncontact dispensing head, the Champion 7600 system dispenses at a speed of 30,000 dots per hour and is capable of dispensing precise dots of material down to a volume of 0.0022 ml when equipped with the manufacturer's True Volume pump. The automatic dispenser works on a precision height- compliant conveyor system with antistatic belt. It also features path optimization, CAD download, and automatic vision alignment. Windows-style software facilitates setup and changes. Creative Automation Co., 11641 Pendleton St., Sun Valley, CA 91352.

Cartridge-filling machine

Achieving consistent and level void-free fills, particularly when filling dual-type cartridges that are typically used to package two-component epoxies, silicones, and urethanes, can be troublesome for some manufacturers. A new benchtop cartridge/syringe dispense system can automatically fill dual-type cartridges to accurate, repeatable preset levels and eliminate the need for secondary operations. The Filla dispensing machine delivers consistent, voidfree fills by combining bottom-up filling with a low-clearance nozzle and adjustable cartridge/material counterbalance system. Initially designed to handle medium- to heavy-viscosity materials, the dispenser also accepts materials of low viscosity. Tridak, 1120 Federal Rd., Brookfield, CT 06804.

You May Also Like