June 1, 1999

Welding & Sealing Equipment

Tube sealer

A sealer can handle PVC, EVA, and polyurethane tubing up to ½ in. OD. An RF generator ensures correct operation for all ac single-phase input voltages from 90 to 264 V ac. The generator powers the pneumatic handheld, midsized sealing head. RF power and dwell time can be controlled by computer or manually via the front panel. The sealer is suitable for closed plastic systems, including large-volume pharmaceutical processing and synthetic cell and tissue processing. SEBRA, 100 N. Tucson Blvd., Tucson, AZ 85716.

Power welder

A welder features a closed-loop ultrasonic power supply, built-in amplitude stepping, and a high-performance converter. The 2000-series is suitable for manual and automated production, with power outputs from 400 to 3300 W, frequencies of 15–40 kHz, and a 1-millisecond sampling rate. Also offered is the FS-180 ultrasonic sealer, which seals knitted, woven, and nonwoven thermoplastic materials without adhesives, chemical binders, or staples. The model features a variable-speed drive mechanism, a pneumatically activated sealing wheel arm, and a forward-angled head. Branson Ultrasonics Corp., 41 Eagle Rd., Danbury, CT 06813-1961.

Ultrasonic welders

Modular ultrasonic welders sense the reactions of the welder to the plastic parts during the process cycle, producing repeatable results regardless of minor part-dimensional variations. The Omega III MCX units have an electronic pressure regulator, an optical encoder, electronic amplitude regulation, and six-parameter monitoring along with traditional time, energy, power, height, and travel modes. Other features include an LCD screen and palm buttons. Forward Technology Industries Inc., 13500 County Rd. 6, Minneapolis, MN 55441.

Benchtop system

A compact, benchtop welding machine fuse welds balloons to catheter shafts that are composed of similar or identical materials. Features of the tubing welding machine include a PLC automated cycle, pneumatically activated heat shields, and independently controlled upper and lower welding jaws. Heat shields that fit the diameter of the shaft are provided to protect the balloon. Interface Associates, 27111 Aliso Creek Rd., Unit 180, Aliso Viejo, CA 92656.

Tip-forming machine

A tip-forming machine offers precision control and power for catheter-processing applications. A dual independent catheter-feeding system has a split pneumatic collet carriage, individual control of air pressure for each side of the tubing feeder, and adjustable pneumatic gripping of the catheter tubing. Front panel LEDs indicate overcurrent, overtemperature, and low water pressure fault status. A digital display provides load current readings, which can be utilized for process parameter verification. PlasticWeld Systems, 3690 Coomer Rd., Newfane, NY 14108.

Power supplies for welders

A company offers a variety of power supplies for plasma and TIG welding. The Plasmafix P+T power supply is fully transistorized, is programmable to 100 weld sequences, and has a welding range of 0.01–50 A for plasma welding and 0.8–50 A for TIG welding. The DT-100 weld programmer provides slopes, pulsing, added program storage, and three analog channels when integrated to the power supply. Process Welding Systems, 601 Swan Dr., Smyrna, TN 37167.

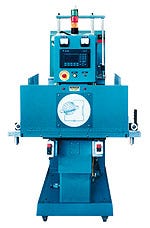

RF sealers

A company offers PLC-controlled RF sealers that automatically monitor and adjust the power settings for 360° tube seals and perimeter seals in real time. An operator interface features historically based, preprogrammed job settings; downloadable load production results; and on-screen diagnostic message capabilities. Kabar Manufacturing Corp., 140 Schmitt Blvd., Farmingdale, NY 11735.

Heat-staking press

A benchtop manually operated heat-staking press is suitable for low-volume production runs and prototyping applications. The 100-series press can perform multiple stakes and insertions on multiple planes in one cycle. Features include a 340-W tapped probe for replaceable tips and a 3 x 3-in. heated platen for custom tools. The press is equipped with six outputs and has two microprocessor-based, autotuning temperature controllers. Sonic & Thermal Technologies Inc., 84 Research Dr., Milford, CT 06460.

Ultrasonic welding system

A 15-kHz ultrasonic welding system is suitable for the joining of large parts, high-performance engineering thermoplastics, and some polyolefins. The Model 1595 can join materials at a greater distance than a 20-kHz welder because of its lower attenuation. It is available in 2500- and 4000-W configurations, and can integrate with a linear optical encoder for precise weld depth control. Sonics & Materials Inc., 53 Church Hill Rd., Newtown, CT 06470.

Assembly system

A 20-kHz assembly system is available as either a thruster system for automated assembly, or as a manual press system. The 220 features a cast aluminum frame; a nonslip, linear motion ball slide assembly; and smooth slide actuation. Other features include 500-, 1000-, 1500-, and 2000-W levels and an independent leveling plate. Dukane Corp., 2900 Dukane Dr., St. Charles, IL 60174.

RF welders

An RF heat-sealing machine manufacturer offers a range of products. Single- and multicycle RF welders can be used to produce products such as IV bags and blood bags. RF sealers and accessories come in a variety of sizes and styles designed to specifications, from 1 to 100 kW. Technicians are available to train operators and maintenance personnel. Hall Dielectric Machinery Company, Inc., 420 Bryant Blvd., Rock Hill, SC 29732.

Copyright ©1999 Medical Product Manufacturing News

You May Also Like