July 14, 2003

Originally Published MPMN July 2003

INDUSTRY NEWS

Watlow Introduces Thermal Systems Consulting Service

|

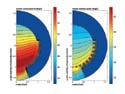

Shown here is a thermal profile of a contrast medium during the in situ heating of an infusion syringe. By using computer modeling techniques, Single Iteration can rapidly and cost-effectively find solutions to thermal heating problems. Click to enlarge. |

Watlow (St. Louis; www.watlow.com) has been supplying industrial heaters, sensors, controllers, and related software for more than 80 years. During that time, it has acquired considerable expertise in providing thermal solutions to a range of industries. Well aware of this knowledge base, customers frequently turn to the company for answers to complex thermal heating problems. Watlow has built on that tradition by introducing its Single Iteration Div. (Fenton, MO; www.singleiteration.com), a team of scientists and engineers experienced in the use of predictive modeling techniques.

"This group is composed of highly trained thermal experts with doctorates or masters' degrees in physics, computer science, and controller theory," says business director Ray Derler. "They form the backbone of the division. We are not simply working on the component level," he stresses. "Single Iteration is involved in the entire heating, sensing, and control loop."

As the name indicates, one of the division's core goals is to help clients avoid multiple design iterations. The staff achieves this by using computational modeling techniques and applying its years of experience in the design and manufacture of thermal parts. "Our assumptions are based on our downstream knowledge of manufacturing requirements and how our products perform in the field," says Derler. By the use of modeling, alternative concepts and technologies are quickly evaluated. When a solution has been found, the subsystem can be rapidly prototyped and integrated into a product for validation. "We manage the project in a holistic fashion. We look at it from a systems perspective," explains Derler.

Although it is part of the Watlow group, Single Iteration routinely seeks expertise elsewhere, as needed. "Our systems approach means that we may require knowledge that is not available at Watlow," says Derler. He cites polymer chemistry as one example. To fully meet the needs of its customers, the firm currently has affiliations with third parties, and it continues to seek more. "We have our tentacles out in the field for various disciplines," says Derler.

Partnering with the division can take a number of forms. "We can be an extension of a company's internal engineering team," says Derler. "Or the OEM can outsource the function entirely to us." Firms adopting the latter approach avoid the added cost and training associated with hiring internal staff, Derler notes. In either case, he stresses, the sooner Single Iteration is brought into a project, the better. "That's when we can do our best work and keep costs low. We want to be a partner, not a crisis manager."

Copyright ©2003 Medical Product Manufacturing News

You May Also Like