Certain tests enable OEMs to fully understand a material’s properties, which is necessary to establish device biocompatibility.

TESTING

|

Gas chromatography is an analytical tool that characterizes aqueous and nonaqueous extractables of device materials. Photo courtesy of NAMSA (Northwood, OH) |

Establishing biocompatibility of medical devices and their components is vital to ensuring product safety. Selection and qualification of materials for medical devices is imperative. To select the appropriate material, it is important to understand the material's composition as well as its physicochemical properties. In addition, the potential for material components to leach into patient body fluids or tissue must be fully understood. Adverse effects and functional failures of medical devices can be related to chemical effects produced by material changes.

Migration of material components, contaminants, or breakdown products (substances generated by manufacturing or sterilization processes) into a patient can have biological effects. Leaching of these same chemicals can adversely affect device functionality by altering its physical and mechanical properties.

A systematic approach to evaluate these parameters can be established using the principles established in ISO 10993.1 For example, characterization of materials is clearly identified by ISO 10993-1 as one of the first steps in an overall biological evaluation. ISO 10993-18 covers requirements for providing information about the chemical components of materials.

After performing a complete and comprehensive characterization study, it is reasonable to conclude that the characterization is appropriate throughout the life of the device. An unfortunate reality is that raw materials used in the manufacture of medical devices are frequently modified. When changes are made, two questions must be considered:

Does the change invalidate the previous material characterization?

How can the effect of this change on the material and, more importantly, on the device, be determined?

It should be noted that, based on a product's regulatory status, other testing also will be needed. For example, a product covered by a 510(k) would require a different, and probably less-extensive, level of testing than one covered by a premarket approval (PMA) application.

As mentioned earlier, ISO 10993-18 plays a pivotal role in the selection process, but the document can also help in dealing with material changes. The focus of this guidance document is on the chemical characterization of materials as an essential part of the overall biological safety of a device. It can also be used to judge chemical and toxicological equivalence. According to ISO 10993-18, equivalency is established when the composition and extractables profiles of the proposed (new) material is equivalent to a clinically established (original) material. Material equivalency refers to the sampling process for a subset of testing to confirm equivalent mechanical, physical, and chemical properties for a particular material or one undergoing minor changes.

Change Control and Material Equivalency

A material equivalency program must be developed as part of a company's change control process to evaluate material changes. One good model uses a subset of chemical characterization testing. First, a screening procedure determines whether the material change produces a discernable change in the material's properties. That procedure also establishes the acceptance-testing criteria. If the screening study indicates that no change is detectable, the assessment is complete. A conclusion that the materials are equivalent can be drawn. If a discernable change is noted in the screening study, then the conclusion is that the materials are not equivalent. From there, the change is investigated in detail to determine its effect on material safety and performance.

Other options are available for determining the effect of a material change. One option would be to do nothing and hope for the best, or, at the other extreme, to repeat the chemical characterization of the material in its entirety. The first option is clearly unacceptable. The second option is not only costly and time-consuming, but is also impractical. A defined screening procedure is the best scenario for determining the effect of any changes.

It is worth noting that, in the course of such a procedure, a manufacturer may also find it useful to perform other screening. Other reviews that might be considered are evaluations of raw materials, methods of manufacture, and comments and data from the raw-material supplier. In addition, the effects of aging, the device's final assembly, and lab testing may enter the equation. However, such tests are beyond the scope of this article.

Screening Test Approach

To confirm equivalent mechanical, physical, and chemical properties for a particular material, or one undergoing minor changes, a few select tests must be performed. These tests categorize specific material extractables in general terms, such as nonvolatile residue (NVR), residue on ignition, buffering capacity, heavy-metals content, ultraviolet absorption, and turbidity.

USP Physicochemical Tests. The USP physicochemical tests for total extractable NVR should be a part of all characterization programs, regardless of how critical the device or its function is. The amount and properties of extractables are evaluated using methods described in monographs 381 and 661 of the current USP.2 Collectively, these tests provide insight into the general chemical nature and amount of extracted substances.

Extracts of both the original and the new material must be done using comparable conditions. Model solvents typically used in the chemical characterization of the original material include purified water (PW) and isopropyl alcohol (IPA) for devices that are skin contacting and externally communicating. PW, IPA, and hexane are often selected for materials used in permanent implants. The USP physicochemical tests based on PW and IPA extracts are particularly useful in defining materials as rich or poor in extractables. The aqueous NVR test is designed to determine the presence of water-soluble substances without regard to their identity. Typically, device materials contain few water-soluble extractables and do not exceed the USP limit of 15 mg of NVR.

|

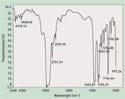

Figure 1. (click to enlarge) Infrared analysis provides a rapid, effective means of identifying a polymeric material and of comparing samples to ensure consistency. |

Infrared Analysis. Used extensively to fingerprint materials, infrared (IR) analysis should be a part of all characterization programs. In this test, IR energy is passed through a thin film of material, and the amount of energy absorbed at various wavelengths is measured. The result is a chart of wavelength versus absorption that is characteristic of the material (see Figure 1). By matching the IR spectrum of an unknown material with that of a known material, proof of identity can be established within the limits of the test method. IR is also used to identify extract residues obtained in USP-model solvent extractions.

Thermal Analysis. Also useful for fingerprinting materials are thermal analyses. In thermal gravimetric analysis, a plot of weight change is made as a material is heated at a known rate. In differential thermal analysis and differential scanning calorimetry, an unknown sample and a reference sample are heated with the aid of a programming device. It measures temperature difference between the two samples. Testing can also be conducted to determine the unique melting point, degree of crystallinity, and glass transition temperature of a polymer. This method helps establish the purity of both the new and original materials.

Gel Permeation Chromatography. Molecular weight is one of the most fundamental properties of any molecule. Almost all physical properties of polymers, synthetic or natural, systematically change as the molecular weight is altered. Unlike pure substances of small molecules, polymer samples have a range of molecular weights. For this reason, polymers do not have one quantity that is their molecular weight. Instead, there are certain average molecular weights, or molecular weight distributions (MWDs). The most common analytical tool for measuring MWD is gel permeation chromatography. In this test, the polymer molecules in a dilute solution are separated according to their hydrodynamic volume when forced through a column of microporous gel particles. Subtle changes in MWD can affect processing properties such as viscosity and cure rates. Mechanical properties such as tensile and impact strength, elastic modulus, hardness, and bond strength can also vary with changes in MWD. This analytical tool can be used to qualify incoming resins or device components as part of a materials qualification program. It can also be used to track lot-to-lot variability or to monitor product stability periodically or after radiation exposure.

Cytotoxicity Test. An in vitro biocompatibility test for cytotoxicity is described in ISO 10993-5. That test can evaluate the presence of any adverse biological effects from extracted chemicals. A minimum essential medium (MEM) extract is evaluated to assess the biological safety of extracted chemicals from the test articles. The extract is examined using a sensitive in vitro method to determine whether leachables extracted from the material would cause cytotoxicity or cell death. The results thereby give “predictive evidence of material biocompatibility.”3

Hemolysis Test. ASTM F756, a standardized ASTM test method, can be used for determining the hemolytic potential of a device or material. The in vitro hemolysis test involves a quantitative measurement of plasma hemoglobin. Device materials are extracted in saline. They are then evaluated to determine whether the presence of any leachable chemicals from the test article could cause in vitro red blood cell hemolysis. This study is based on the requirements of ISO 10993, Part 4, “Selection of Tests for Interactions with Blood.”

Using these few tests, it is possible to evaluate and confirm equivalence with respect to mechanical, physical, chemical, and toxicological properties for any proposed material. It is important to remember that the level of testing must be adjusted to address the criticality of the end use of the device. Therefore, it is reasonable to conclude that testing performed for a surface device would be the least intensive, while an externally communicating or implant device would require more evaluation. Table I shows suggested tests per device category and can be used as a general guideline for test method and protocol development.

Acceptance Criteria for Equivalency

All measurements have some variability. The trick is to be able to tell when an experimental value is within normal variation or is outside of the ordinary. Control charts are designed to make this distinction possible. As long as all points lie inside the upper and lower control limits, the measured value is presumed to be normal or a common cause of variation.

When a data point (experimental variable or test) falls outside the limits of the control chart, it is necessary to identify a reason for the variation. Test values that fall outside limits are labeled not equivalent and further chemical characterization tests are needed to determine the effect of the change. This approach can also be used as a raw material quality control test. It is designed to detect large variations or undesirably high or low properties.

|

Figure 2. (click to enlarge) Documenting quality control can be done using control charts. UCL = upper control limit; LCL = lower control limit. |

Choosing the right control chart is essential when using this tool, since a data point can be quantitative (variable data) or qualitative (attribute data). Fourier transform infrared (FTIR) spectroscopy and cytotoxicity and hemolysis tests result in qualitative data and have pass-fail criteria applied to them. If any test articles fail or do not meet the specified limit, then the material is considered not equivalent. Other tests are quantitative and yield numeric values. For those types of quantitative tests, using a control chart to evaluate the results is extremely valuable. A typical control chart constructed by plotting NVR versus IPA sample extractions is shown in Figure 2.

The upper and lower control limits are established by calculating the mean and standard deviation of the test results. Then, control limits are set to the standard deviation of the mean. This approach can be used on any experimental or test result and can be plotted as shown.

If the various test results indicate that there are no discernable changes, then no further testing is required and the test sample material can be qualified as equivalent. If there are discernable or significant changes noted, then the material is judged not equivalent. The material is either rejected or subjected to additional tests to further investigate the change and its potential overall biological or toxicological significance.

Conclusion

|

Table I. (click to enlarge) Suggested tests per device category. This table can be used as a general guideline for test method and protocol |

ISO 10993-18 states that sufficient qualitative information shall be obtained to allow a comparison to determine whether a material is equivalent to that used in a device with the same clinical exposure and use and having had the same manufacturing and sterilization processes applied. By executing the simple and inexpensive tests listed in Table I, material equivalency can be established. These tests provide a powerful way to evaluate and confirm equivalency with respect to mechanical, physical, chemical, and toxicological properties for any proposed material. When performed regularly, these tests can serve as quality control measures and as test methods to evaluate and control change.

There are many benefits to performing these routine or quality control tests. When used regularly, they can minimize the risk of an adverse event or failure in the future. They can also provide the means to detect and evaluate known or suspected material changes, and they can be used to ensure that a material change will not compromise device quality or safety. Performing these tests routinely is prudent. It should lower costs during the life of the device and ensure compliance with FDA and ISO guidance documents. Finally, these test methods can reduce risk significantly and can provide assurance that the material and the medical device are safe for their intended use.

David Albert is senior scientist at Northwood, OH-based NAMSA and can be reached at [email protected]. Amy Hoffmann serves as technical specialist supporting NAMSA's chemistry department. Contact her at [email protected].

References

1. ISO 10993, “Biological Evaluation of Medical Devices” (Geneva: International Organization for Standardization, 2003).

2. United States Pharmacopeia (Rockville, MD: U.S. Pharmacopeial Convention, 2007).

3. Richard Wallin and Edward Arscott, “A Practical Guide to ISO 10993-5: Cytotoxicity,” Medical Device & Diagnostic Industry 20, no. 4 (1998): 96–97.

Bibliography

Albert, David. “Materials Characterization as an Integral Part of Global Biocompatibility.” Medical Plastics and Biomaterials 11, no. 4 (1997): 16–23.

Albert, David. “The Growing Importance of Materials Characterization in Biocompatibility Testing.” Medical Device & Diagnostic Industry 24, no. 3 (2002): 50–59.

Albert, David. “The Important Role of Material and Chemical Characterization in Device Evaluation,” Medical Device Technology 15, no. 5 (2004): 15–18.

Albert, David and Taylor, Stephanie. “Biological Evaluation of Medical Devices—The Role of Chemical and Material Characterization” in Business Briefing: Medical Device Manufacturing & Technology 2004. London: Touch Briefings, 2004, 48–51.

Albert, David and Wallin, Richard. “A Practical Guide to ISO 10993-14: Materials Characterization.” Medical Device & Diagnostic Industry 20, no. 2 (1998): 96–99.

Sibilia, John. A Guide to Materials Characterisation and Chemical Analysis. New York: VCH, 1998, 13–40.

Copyright ©2007 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like