April 1, 1999

Testing and Inspection

Package-integrity test system

A package-integrity test system provides objective, nondestructive quality control for the sterile integrity of porous medical device packages. Suitable for use in package development, validation, and routine quality inspection on the production floor, the Sealcheck 210 system detects and reports the location of thin channel leaks. It features retrievable validation data and a graphic display. True Technology Inc., 143 California St., Newton, MA 02458.

Portable helium leak detector

Featuring an oil-free diaphragm and molecular drag pump, a portable helium leak detector works in cleanrooms, pharmaceutical manufacturing facilities, and other environments where contamination is a concern. Operation, calibration, and shutdown of the MS-40 Dry detector are fully automated, and the time from start-up to operation is less than 3 minutes. The unit's leak standard compensates for temperature, ensuring accurate measurements. The leak detector includes a 5-year warranty. Veeco Instruments Inc., Terminal Dr., Plainview, NY 11803.

Accelerated stress test system

For use on medical electronic products, an accelerated stress test system requires hours to reveal how a product will hold up during years of use. Stresses are placed on products through repetitive-shock vibration and temperature change rates that exceed 70°C per minute. The liquid-nitrogen-cooled chamber features high volume and adjustable air distribution to direct airflow rapidly over the product. Access to the internal chamber is provided through doors on the front and back of the unit. The vibration system uses a thermal isolation system to minimize thermal loading on the chamber. Up to 16 accelerometer and 8 thermocouple monitoring channels allow the user to see which stresses are being applied to the product, and the product test system electronically stimulates and monitors multiple product parameters while under stress. Thermotron Industries, 291 Kollen Park Dr., Holland, MI 49423.

Axial testing system

A system is suitable for testing medical devices and biomechanical constructs, characterizing biomaterial properties, and simulating biological forces and displacements. Designed to run fatigue cycles at frequencies up to 30 Hz, the 858 Mini Bionix II system can be purchased as an axial-only, an axial/torsional, or an axial/rotational system. It provides accurate testing under axial loads up to ±25 kN with standard displacements of ±50 mm. The system fits on a laboratory bench, and is available with a specially designed cart. MTS Systems Corp., 14000 Technology Dr., Eden Prairie, MN 55344-2290.

Capillary rheometer

Offering sophisticated material characterization, data analysis, and reporting capabilities, a benchtop capillary rheometer incorporates unique algorithms to allow the automatic determination of polymer-melt stability. For testing a wide range of materials, the LCR6000 benchtop rheometer uses a three-zone heater and an adaptive temperature-control algorithm to provide precise and uniform heat up to 430°C. Advanced electronics enable up to 45 shear-stress or shear-rate points to be obtained during each test. In addition, bidirectional communications enable test parameters to be downloaded from a PC. Dynisco Polymer Test, 115 Thousand Oaks Blvd., Morgantown, PA 19543-0709.

Leak tester

Featuring flexibility and simple setup and operation, a leak tester offers three inputs and three outputs to interface to PLCs or external devices. The Sentinel C-20 provides accurate measurement through an internal, NIST-traceable leak orifice for its automatic calibration routine. Inputs include a start and stop test and a programmable input, and outputs include accept, reject, and programmable output. The pressure-loss value, process drift correction, calculated leak rate, and accept/reject results are stored for up to 100 parts and can be easily viewed by the operator or output to a printer. Cincinnati Test Systems Inc., 5555 Dry Fork Rd., Cleves, OH 45002.

Seal-strength tester

An automated seal-strength package tester is available to produce quantitative data for compliance with the requirements of ISO 11607. The BT-1000 performs burst, creep, and creep-to-failure tests on porous and nonporous packages. Pouches, header bags, and lidded trays are among the package configurations that can be validated and controlled in the manufacturing process. The unit will also perform leak tests on seals for nonporous package materials such as foil or poly film packs. T.M. Electronics Inc., 330 Tacoma St., Worcester, MA 01605.

Lever-operated test stand

Capable of producing up to 750 lb of force, a lever-operated test stand allows for several years of repetitive testing. Measuring 6 x 8 x 26 in. and weighing 16 lb, the Model TSA stand can be supplied with an optional digital travel display and a horizontal or wall mounting kit. The rack-and-pinion mechanism allows for a total of 8½ in. of travel. Applications include material testing, sporing testing, peel testing, and product integrity testing. Mark-10 Corp., 458 W. John St., Hicksville, NY 11801.

Instrumented indentor

An instrumented indentor is one of five interchangeable platforms on a workstation used to measure mechanical strength. The indentor offers ranges from 1 g to 200 kg, and provides reports on hardness, elastic modulus, yield strength, maximum stress, and work-hardening constant. In addition, other platforms can be installed to measure tensile and flexural stress and strain, torque, adhesion, friction, and wear. The same platform can receive modules for five coating-adherence tests; three bonding-agent strength tests; torque, tear strength, and piercing tests; and microcircuit technology tests. Quad Group Inc., 1815 S. Lewis St., Spokane, WA 99224.

Testing and evaluating equipment

An engineering company produces testing equipment for medical device manufacturers. The company offers sharpness tests for needles and blades, leak tests, flow-rate measuring, product and methods development, and process validation. It specializes in the quality control of medical devices, including needles, syringes, catheters, and other products. Melab Medizintechnik und Labor GmbH, Gartenstr. 12, Fiolzheim 71292, Germany.

Universal testing systems

Powerful, compact benchtop testing machines determine tension, compression, shear, flexural, and other properties of metals, plastics, composites, rubber, wire, textiles, adhesives, ceramics, and other materials. S-series benchtop universal testing machines can also be used to analyze finished products, including IV tubing, hypodermic needles, latex gloves, scalpels, and other medical instruments. Five models of the machines are available. Machine features include a digital display of force and displacement during testing, a real-time autoranging graphic display, cyclic control of the force or strain extension between zero and a selected value, and storage and retrieval of test parameters. Tinius Olsen Testing Machine Company, Inc., P.O. Box 429, Easton Rd., Willow Grove, PA 19090-0429.

Air-leak tester

Featuring a main unit and up to four intelligent detector modules, a leak tester is capable of synchronous and asynchronous testing. The Model Q6000 air-leak tester's detector modules can be connected to the control unit from up to 100 ft away, and can store up to 10 programs each. Each gas box functions independently of the others, regardless of its power or operational status. Program editing or removal is password protected at the control unit. For each leak test, the system provides a graphic display of test status and pressure profiles. ITI Qualitek, 267 Boston Rd., North Billerica, MA 01862-2310.

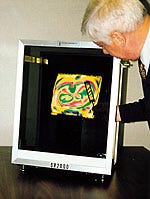

Strain viewer

A large-field polariscope strain viewer is used for the quality control of all types of transparent polymers. Manufacturers can set up the unit horizontally or vertically to view the residual strains in their products. Quantitative measurement of retardation and birefringence can be obtained with an optional compensator. The SV-2000 unit's testing methods are nondestructive. Strainoptic Technologies Inc., 108 W. Montgomery Ave., North Wales, PA 19454.

Leak and flow tester

Combining simple operation and setup with several advanced features, a leak and flow tester allows users to customize test programs to meet specific requirements. The Sprint-1100 system includes a pressure-plot graphic display and data-logging capabilities for RS-232 and PC memory cards. In addition to its multiple testing capabilities, the system also performs statistical analysis of test results. At a single test station, users can test multiple components that have different configurations. Uson, 5215 Hollister, Houston, TX 77040.

Microbial air samplers

A line of lightweight, portable air samplers provide repeatable results in maintaining a contamination control monitoring program. The standard RCS centrifugal air sampler offers reliable results when simple monitoring is required. The RCS Plus samples 50 L of air per minute and functions in laminar-flow areas. Capable of sampling 100 L of air per minute, the RCS High Flow features removable components and includes an infrared remote control with a keypad and integrated display. All the samplers use Hycon agar media strips to ensure accurate results. Biotest Diagnostics Corp., 66 Ford Rd., Ste. 131, Denville, NJ 07834.

Pneumatic leak tester

Capable of testing parts of different sizes and changing internal volumes, a pneumatic leak tester minimizes the required cycle time for each part tested. The System 100 leak tester features a mass-flow test method, which provides a direct readout of leak rate regardless of the part's internal volume. The unit's plumbing pneumatics are contained in a compact manifold with pilot-operated valves, eliminating many fittings and connections and providing a leak-free system. The tester can operate on a stand-alone basis or can be integrated into a fully automated assembly. Phase One Instruments, Div. of Vacuum Instrument Corp., 3203 Plainfield Rd., Dayton, OH 45432.

Dual-channel leak detector

By simultaneously testing two parts or conducting different tests on the same part, a dual-channel leak tester enables manufacturing companies to use only one tester for multiple tasks. The unit features extended memory and retains more data than earlier models, saving up to 1000 test records for display. Measuring 6.54 x 12.63 x 15.75 in., the unit can be incorporated easily into automated assembly and test systems. Offering cycle times from 0.3 to 2 second on test-part volumes up to 25 cm3, the M-1075 leak detector has a sensing range of up to 80 cm3 per minute at test pressures up to 100 psig. The system offers PC or PLC compatibility for interfacing with machine controls, data highways, or host computers. Intertech Development Co., 7401 N. Linder Ave., Skokie, IL 60077.

Case inspection system

A compact, high-speed case inspection system detects missing, empty, or broken containers in opened or closed cases. The FT-100 system can also detect grossly underfilled containers and cases that have absorbed the spilled contents of a broken bottle. The inspection head houses a radiation source and detector system that measures the relative density of the case as it passes through the inspection zone. The system can inspect cardboard, paper, plastic, or wood cases on fixed- or variable-speed lines. Several tunnel widths are available, and the system can be installed on existing production lines with minimal modifications. Industrial Dynamics International Inc., 2927 Lomita Blvd., Torrance, CA 90505.

Copyright ©1999 Medical Product Manufacturing News

You May Also Like