June 1, 1999

Lasers

Stent-Cutting System Provides High Throughput

Features high-repetition-rate laser

FACTORS SUCH AS cutting speed, the degree of automation, and the time to convert a design into a cutting program all contribute to throughput in stent cutting. To address these factors, Lumonics (Kanata, ON, Canada) has added the following features to its StentCut 1000 stent-cutting system: automated tub indexing, software for quickly converting designs to cutting programs, control (System 94W/PC) that is network ready to speed transfer of stent-cutting programs to the laser cutting system, and Laser Process Manager software for documenting process conditions.

The StentCut 1000's laser is a high-repetition-rate pulsed Nd:YAG. It features electronic energy control for output stability, electronic pulse width control for accurately matching peak power and average power, and a diffuse ceramic cavity.

Lumonics provides training and service programs to support its laser cutting system. The training program covers programming, operation, and routine maintenance. Optional service-level maintenance courses are also offered.

For more information, contact Lumonics at 613/592-1460.

Display Technology

Flat-Panel LCD Provides Space Savings and Other Benefits

The display meets worldwide regulatory requirements

ADVANCEMENTS IN LCD technology have allowed OEMs to build more-compact medical devices. The MediFlat 15 flat-panel display from Pixelink Corp. (Hudson, MA) is one such compact display. It is smaller and lighter than conventional displays. In addition, being specifically designed for the medical device industry, it meets all IEC standards, CE requirements, and FDA regulations and does not pose electromagnetic interference problems with other medical equipment.

The MediFlat 15 features a self-contained power supply, eliminating the need for a "brick" or wall-mounted power supply. Thus, OEMs need not be concerned about external components, which can get lost or disconnected from the display.

When OEMs develop their own video specifications or require the display to produce a 640 x 480-pixel image on a 1024 x 768 LCD, the resulting imaging is full of distortion and jagged edges. The MediFlat 15's custom ASIC allows for scaling of the image to eliminate such distortions. The scaling feature will not interfere with the OEM's software, and the ASIC works seamlessly with all operating systems.

OEMs use hundreds of different video resolutions and refresh rates. The MediFlat addresses these resolutions with an automatic picture setup. When the horizontal and vertical positioning is adjusted, the display automatically remembers the setting every time the monitor is turned on. Acceptable resolutions addressed are 640 x 480 up to 1024 x 768 at 75 Hz.

Other features include VESA standard mounting, autobrightness control, and optional touch screen technology.

For more information, contact Pixelink Corp., at 978/562-4803.

Design Equipment

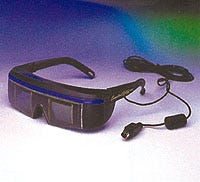

Stereoscopic Eyewear Allows Viewing of Complex 3-D Images

Enhances design review

MECHANICAL DESIGNERS working with complex 3-D images may be interested in CrystalEyes Wired, a stereoscopic eyewear system developed by StereoGraphics Corp. (San Rafael, CA). CrystalEyes Wired delivers high-definition Stereo3D viewing capability on Windows NT workstations in conjunction with compatible software and standard workstation displays. This accurate visualization of complex 3-D images helps reduce errors and facilitates design reviews.

A person sees with both eyes, each with a slightly different perspective, to perceive depth. Stereo3D uses computer technology to recreate this stereoscopic way of perceiving depth. The technology was developed to take advantage of the new generation of OpenGL graphics cards using the VESA three-pin mini-DIN connector. The user plugs the system's three-pin connector into a compatible graphics card, and the eyewear is automatically activated whenever a Stereo3D application is running. The technology delivers a very realistic visual representation of complex digital models, enabling engineers to throughly understand 3-D information.

For more information, contact StereoGraphics Corp. at 415/459-4500.

Sterile Manufacturing Guide Released

The Society for Pharmaceutical and Medical Device Professionals (ISPE) has released its Sterile Manufacturing Facilities Baseline Guide, which addresses the design, construction, commissioning, and qualification of facilities designed for aseptic processing of formulated products. The guide, created to provide an interpretation of regulatory requirements, focuses on engineering issues and how to provide cost-effective facilities. For information on purchasing the guide, contact the society at 813/960-2105.

Copyright ©1999 Medical Product Manufacturing News

You May Also Like