April 10, 2004

Originally Published MPMNApril 2004

INDUSTRY NEWS

Stent Advances Pavethe Way for Drug-Eluting Coating Suppliers

MelodyLee

|

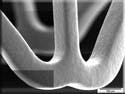

A stainless-steel coronary stent is coated with Hemoteq's polymer matrix containing Paclitaxel. |

Drug-eluting stents may have only been commercially available in the United States for about a year, but the facts already point to a huge demand. According to Cordis (Miami Lakes, FL; www.cordis.com), nine months after FDA approval, its Cypher stent has been used in nearly 60% of U.S. coronary stent procedures. Recently, Cordis and Guidant Corp. (Indianapolis; www.guidant.com)reached an agreement regarding the marketing of Cypher. Guidant, a developer of cardiac and vascular treatment, will promote the stent. In addition, the companies will develop another version of the device that uses Guidant's Multilink vision stent-delivery system.

Following closely in the race to market drug-eluting stents is Medtronic (Minneapolis;www.medtronic.com). It has begun the third phase of clinical trials for its Endeavor drug-eluting coronary stent. If its stays on track, the company predicts product approval in the United States in late 2005.

The movement toward this market among OEMs did not go unnoticed by suppliers, as the key to the success of drug-eluting stents may be in finding the right coating. With the right surface treatment, a stent can more effectively prevent restenosis, or the reclogging of arteries. The first six months after stents are inserted are critical, as 10-20% of balloon angioplasty patients experience restenosis. Several companies offer potentially lifesavingcoatings, while others are still in the research phase.

Nanocoating firm Hemoteq (Würselen, Germany; www.hemoteq.com)has been offering Ouverture since the end of 2002. The polymer matrix combines two coatings that are hemocompatible and reduce the risk of reclogging. Nearly any metallic stent material and design can be processed with the drug-free coating.

|

The coating on Angiotech's Taxus Express stent demonstrates drug-eluting properties. |

After the first few months postsurgery, "there is no real need for a drug or any coating," says Ingolf Schult, marketing manager for Hemoteq. "Many doctors feel more comfortable with a bioresorbable coating that will disappear after the drug-eluting phase. That is why Hemoteq selected biodegradable polymers for Ouverture." Schult adds that some of the biostable polymers that are being used for stent coatings are not really biocompatible and may interfere with antirestenosis therapy.

STS Biopolymers Inc. (Henrietta, NY; www.stsbiopolymers.com), recently acquired by Angiotech Pharmaceuticals Inc. (Vancouver; www.angiotech.com), also offers a drug-eluting coating technology. The Medi-Coat system consists of drugs trapped in a mix of hydrophilic and hydrophobic polymers.

Following the recent acquisition, the coating system will be offered to manufacturers with an added advantage. Historically, STS Biopolymers was approached by OEMs wanting a certain drug to be released from a device. The company would then combine its coating formula with the provided drug. Angiotech plans to continue doing so, but also hopes to provide the manufacturers with the drug itself. "We want to go to the manufacturer and say, 'Here is what we think the clinical problem is, and here is the drug that we think will work,'" says Bill Hunter, president and CEO of Angiotech. "We're providing the complete packaging and bringing the drug and the coating."

An advantage of using Medi-Coat "is its flexibility," adds Hunter. "It isn't just one coating that suits all purposes. Medi-Coat is a blend of several different polymers. That means that there's usually one polymer in the combination that's suitable for delivering the certain drug, and you can use more or less of that particular polymer [when making the coating]."

An ionic plasma deposition (IPD) process is used by Ionic Fusion Corp. (Longmont, CO;www.ionicfusion.com) to give stent makers another choice in antirestenosis and drug delivery. It currently lays down FDA-approved materials for radiopacity on stents or other surface coatings to improve stent characteristics. The company is also involved in advanced research work to improve the drug-eluting properties of its coatings.

|

Medtronic's Endeavor stent is in its third phase of clinical trials with expected approval in late 2005. |

According to the company's president and COO Joe Ryan, the IPD process has several characteristics that make it distinctively different from traditional coating methods. One advantage is that the process can be done at room temperature on any substrate. For example, this enables a metal made of stainless steel, nickel, or another alloy to retain its mechanical or tensile strength or any inherent properties.

"Because we're actually impregnating the metal ions into the substrate of the stent, the adhesion is extraordinary," says Ryan. "It literally becomes a part of the substrate material. This has been proven by work with NASA and MIT. In NASA's case, the metal ions went into the material up to 13 microns."

The company is creating "more highly porous surfaces that would allow for greater volumes of drugs to be held by the stent, both on the inner and outer diameters," adds Ryan. "This process allows us to put different surface characteristics on [different parts of the stent]."

Copyright ©2004 Medical Product Manufacturing News

You May Also Like