July 1, 1998

Component

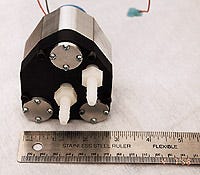

Scroll Compressor Runs Quietly and Efficiently

Valveless unit can reduce equipment maintenance

PRIMARY TECHNOLOGIES for air compressors and vacuum pumps used in medical equipment have traditionally been rocking piston, linear, and piston, all of which have valves that create noise and inhibit efficiency. The range of options has grown, however, with the availability of a scroll-type compressor, also known as a ported compressor.

While scroll compressors were originally developed for the refrigeration industry, an oilless ported compressor from Air Squared Inc. (Hamilton, OH) is appropriate for medical applications including dialysis machines, ventilators, and nebulizers.

While conventional valve compressors make noise with each revolution involving the opening and closing of valves, the scroll compressor has no moving valves and, therefore, runs quietly and oilfree. One manufacturer incorporated it into an oxygen concentrator, cutting noise by 50% and increasing projected time between maintenance from 10,000 to 25,000 hours.

The operating elements of a scroll compressor comprise two identical involutes—a fixed scroll and an orbiting scroll—that form right- and left-hand components. One scroll is indexed 180° with respect to the other, enabling the two to mesh. The orbiting scroll is driven by an electric motor; as it orbits around the fixed scroll, crescent-shaped gas pockets (formed by the meshed scrolls) spiral toward the center and diminish in size. Gas is trapped in the two diametrically opposed gas pockets and compressed as the pockets move toward the center. The compressed gas is then exhausted through a discharge port at the center of the fixed scroll. Because the discharge port is isolated from the inlet, no valves are needed; thus, noise is reduced and durability increased.

In most cases, the scrolls are made of precision-machined aluminum, although some applications permit the use of injection-molded plastic scrolls. Modern machine tools can produce involutes in 1 to 5 minutes with accuracies of 0.0002 to 0.0005 in. Tight machining tolerances minimize bypass leakage and promote efficiency. Oilless operation requires a smooth 16-µin. surface finish on the base for compatibility with the self-lubricating plastics used in the floating tip seal.

Advantages of using a scroll compressor include continuous air delivery, which virtually eliminates discharge pulsation and associated noise; rotary motion that can be balanced for vibration-free, quiet operation; a design composed of just two primary moving parts; running speeds up to 3450 rpm; and rubbing velocities that are 30–50% less than reciprocating or rotary compressors.

For more information on scroll compressors, contact Air Squared Inc. at 513/755-2559.

Video System

Camera Delivers High-Quality Imaging in Small Package

CCD camera features remote control accessibility

A COLOR CCD camera measures just 22 mm wide x 22 mm high x 86 mm deep, or roughly the size of a cigar. According to its manufacturer, it is one of the smallest CCD cameras available that features DSP and remote computer-control capability. Made by Hitachi Denshi Ltd. (Woodbury, NY), the KP-D8 camera offers optional remote control via an RS-232 port.

Because of its small size and light weight, image quality, and remote accessibility, the KP-D8 is well suited for medical applications including endoscope cameras used in office or surgical settings, eye surgery devices, intraoral cameras, and medical headgear.

The camera is controlled by a PC with Windows-based software. "A video engineer can set up parameters for optimal viewing capability before surgery so that there need not be any messing with the settings," says Mike Ames, regional manager for Hitachi's Industrial Video Systems (IVS) Div.

The camera's use of proprietary DSP technology enables very high-quality imaging. Features include an automatic 2H enhancement, automatic aperture correction, backlight correction, as well as three white-balance modes (autotracking white, memory, and manual adjustment of red and blue gains and black balance).

"The camera provides a very high-quality picture, can be mounted anywhere, and can be controlled via a personal computer. Plus, with its all-metal housing, it is extremely rugged," says IVS vice president Phil Gantt. Furthermore, the metal casing dissipates heat generated by the camera such that it is not too warm to the touch—an important feature for a camera small enough to fit in the palm of a hand.

Other features of the KP-D8 include a 1/3-in. CCD with microlens for increased light sensitivity, 470 TV lines of resolution, and an autoelectronic shutter and electronic shutter. It has the ability to provide composite and Y/C outputs. The only requirements for operating the camera are a lens and dc power source.

For more information, contact Hitachi Denshi Ltd., Industrial Video Systems Div., at 516/921-7200.

New Technology

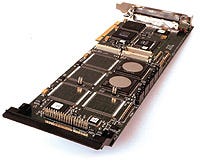

DSP Enhances Medical Instrumentation

Chip captures and processes signal data at very fast rates

WHILE DIGITAL signal processor (DSP) technology is widely used for data processing in the wireless communications and personal electronics industries, its potential is just starting to be explored by medical manufacturers. A DSP is a programmable semiconductor chip that accepts a stream of digital data and performs mathematical algorithms. DSPs are designed for real-time applications, capturing and processing signal data at very fast rates.

The future of DSPs for the medical industry will be defined not only by improved image quality (and subsequent diagnoses), but also by changes in the way equipment is designed. From a cost standpoint, DSPs are starting to replace application-specific integrated circuits (ASICs) in x-ray systems. DSPs could also pave the way for real-time CT-scan analysis.

Blue Wave Systems (Dallas) works closely with DSP manufacturers and independent software companies to develop and manufacture PC and VME DSP boards for medical imaging applications.

Blue Wave's PCI/66-P2 SHARC board is designed for use in testing and instrumentation equipment. It features two SHARC DSP processors from Analog Devices (Norwood, MA); a PMC module site for I/O; and a high-speed, 32-bit PCI interface. The PMC/Q20DS module has four input and output channels, each supported by an independent sigma-delta conversion circuit for reliable, phase-accurate conversion in both directions. By incorporating these features, the PCI/66-P2 SHARC board provides an economical DSP system for high-resolution imaging applications.

The PCI/66-P2 can be used in applications requiring up to 16 input channels. A wide range of modules from third-party vendors can provide the board with additional processing and I/O facilities including analog, digital, imaging, and networking interfaces. Blue Wave's IDE6000 software-support package handles all configuration functions.

With the availability of DSPs, medical equipment manufacturers can look forward to fast, inexpensive, simple chips for both high-end and commodity equipment and instrumentation.

For more information, contact Blue Wave Systems at 972/277-4600.

You May Also Like