May 16, 2009

Originally Published MPMN May 2009

SPOTLIGHT

Prototyping and Rapid Prototyping

Implantable-electrode prototyping services Providing prototyping and short-run manufacturing services for implantable electrodes and medical devices, a contractor uses customer specifications to develop electrodes that are used in neuromodulation, cardiac pacing, muscle stimulation, and neural-signal recording applications. It also performs prototype and short-run manufacturing of customer-designed active implants and external control equipment. Following a variety of proprietary designs from rough concept sketches to formal CAD drawings, the vendor supplies electrodes and medical devices to researchers at universities and to commercial entities, assisting clients to meet their development and production requirements.

Providing prototyping and short-run manufacturing services for implantable electrodes and medical devices, a contractor uses customer specifications to develop electrodes that are used in neuromodulation, cardiac pacing, muscle stimulation, and neural-signal recording applications. It also performs prototype and short-run manufacturing of customer-designed active implants and external control equipment. Following a variety of proprietary designs from rough concept sketches to formal CAD drawings, the vendor supplies electrodes and medical devices to researchers at universities and to commercial entities, assisting clients to meet their development and production requirements.

Ardiem Medical Inc.

Indiana, PAwww.ardiemmedical.com

Rapid prototyping of thermoplastics A custom manufacturer of medical device components and subassemblies offers rapid prototyping of thermoplastic products. Based on a solid model or CAD drawing, the company can produce a finished sample in approximately two weeks. A feature of the company’s prototype molds is that they are built as production molds and can be used to manufacture up to 100,000 cycles. Because the prototype molds are treated as production-quality molds, the quality of the product derived from them is similar to the quality achieved from high-volume production molds, enabling customers to introduce products to the market while the high-volume production tool is being built. The company also provides clients with rapid prototyping services through partnerships with specialized mold builders located near its manufacturing facilities.

A custom manufacturer of medical device components and subassemblies offers rapid prototyping of thermoplastic products. Based on a solid model or CAD drawing, the company can produce a finished sample in approximately two weeks. A feature of the company’s prototype molds is that they are built as production molds and can be used to manufacture up to 100,000 cycles. Because the prototype molds are treated as production-quality molds, the quality of the product derived from them is similar to the quality achieved from high-volume production molds, enabling customers to introduce products to the market while the high-volume production tool is being built. The company also provides clients with rapid prototyping services through partnerships with specialized mold builders located near its manufacturing facilities.

APEC, a div. of Helix Medical

Baldwin Park, CA

www.apecplastics.com

Laser-machining-based prototyping  Providing prototyping services using laser machining, a contract manufacturer offers proof-of-concept services and feasibility samples during the design and evaluation stages of outsource manufacturing. It uses laser, mechanical, and organizational energy—combined with automation—to prototype, plan, and manufacture products made from a range of materials. Automation expertise enables the supplier to machine materials with precise and challenging geometries with up to eight axes of motion, regardless of surface, substrate material, or shape. The company can provide prototypes for a range of medical device components, including neurostimulation lead assemblies, electrophysiology and cardiology catheters, and pacing and defibrillating leads.

Providing prototyping services using laser machining, a contract manufacturer offers proof-of-concept services and feasibility samples during the design and evaluation stages of outsource manufacturing. It uses laser, mechanical, and organizational energy—combined with automation—to prototype, plan, and manufacture products made from a range of materials. Automation expertise enables the supplier to machine materials with precise and challenging geometries with up to eight axes of motion, regardless of surface, substrate material, or shape. The company can provide prototypes for a range of medical device components, including neurostimulation lead assemblies, electrophysiology and cardiology catheters, and pacing and defibrillating leads.

Avicenna Technology Inc.

Montevideo, MN

www.avicennatech.com

Rapid prototyping services Supplying rapid prototyping services to medical device, instrumentation, and implant OEMs, a contract manufacturer employs proprietary tooling and processes to provide prototypes of complete devices, welded and mechanical assemblies, machined components, metal stampings, tubing, surgical scissors, and sharps. Capable of meeting short-lead-time requirements, the company utilizes metal stamping, CNC machining, wire EDM, grinding, and other processes. To meet rapid prototyping requirements, the company also uses an array of high-tech equipment, including four-axis machining centers with 50,000-rpm spindle speeds and wire EDMs.

Supplying rapid prototyping services to medical device, instrumentation, and implant OEMs, a contract manufacturer employs proprietary tooling and processes to provide prototypes of complete devices, welded and mechanical assemblies, machined components, metal stampings, tubing, surgical scissors, and sharps. Capable of meeting short-lead-time requirements, the company utilizes metal stamping, CNC machining, wire EDM, grinding, and other processes. To meet rapid prototyping requirements, the company also uses an array of high-tech equipment, including four-axis machining centers with 50,000-rpm spindle speeds and wire EDMs.

Medical Device Solutions LLC

Meriden, CT

www.lyons.com

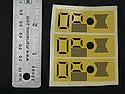

Rapid laser and plotter prototypes Rapid laser and plotter prototypes are produced on customized machinery by an FDA-compliant and ISO 9001:2000–certified contract manufacturer of medical device components. The company’s capabilities include manufacturing parts from in-stock materials using a variety of technologies, including computer-generated prototyping, flatbed and rotary laser cutting, laser and water-jet cutting, blade-cutting plotters, multilayer laminations with pressure-sensitive adhesives, and composite laminations. With expertise in the manufacture of diagnostic components, electromedical devices, bandages, and medical tapes, the company offers prototyping services that can be performed from CAD files, eliminating the need for tooling.

Rapid laser and plotter prototypes are produced on customized machinery by an FDA-compliant and ISO 9001:2000–certified contract manufacturer of medical device components. The company’s capabilities include manufacturing parts from in-stock materials using a variety of technologies, including computer-generated prototyping, flatbed and rotary laser cutting, laser and water-jet cutting, blade-cutting plotters, multilayer laminations with pressure-sensitive adhesives, and composite laminations. With expertise in the manufacture of diagnostic components, electromedical devices, bandages, and medical tapes, the company offers prototyping services that can be performed from CAD files, eliminating the need for tooling.

Marian Inc.

Indianapolis

www.marianinc.com

Rapid prototyping programs A manufacturer of fine-wire and tubing components for the medical device industry supplies mandrels, core wires, and other components. The company’s FastLane rapid prototyping program provides straight mandrels in stainless steel, PTFE-coated stainless steel, and nitinol in lengths up to 73 in. with a variety of end treatments. For prototype orders up to 100 pieces, the FastBack program offers more-complex components and secondary services such as single-taper grinding, pressing, flattening, wire forming, coating removal, miniature assemblies, and heat treating. Wire diameters range from 0.003 to 0.125 in., depending on the material used.

A manufacturer of fine-wire and tubing components for the medical device industry supplies mandrels, core wires, and other components. The company’s FastLane rapid prototyping program provides straight mandrels in stainless steel, PTFE-coated stainless steel, and nitinol in lengths up to 73 in. with a variety of end treatments. For prototype orders up to 100 pieces, the FastBack program offers more-complex components and secondary services such as single-taper grinding, pressing, flattening, wire forming, coating removal, miniature assemblies, and heat treating. Wire diameters range from 0.003 to 0.125 in., depending on the material used.

Wytech Industries

Rahway, NJ

www.wytech.com

For more information on prototyping and rapid prototyping services, visit the Contract Manufacturing and Packaging Services category in our North American Suppliers Directory.

Copyright ©2009 Medical Product Manufacturing News

You May Also Like