The devices worthy of a Medical Design Excellence Award feature some of the smartest details in the field of medical devices. Design teams can successfully tackle problems by listening to users and working to improve safety and efficacy. Some of the winning designs focused on cleanliness and user habits, others on optimizing power sources, and still others on engineering simplicity to improve surgical techniques. All of them paid attention to the details.

March 30, 2011

Freedom LED: No Hands, No Wire

If you’ve been to the dentist lately (let’s hope you have) it’s likely that you sat under a very big and bright light. The person with their fingers in your mouth probably had to adjust that light a few times. Or perhaps the dentist or hygienist was wearing lighted headgear. You may not have noticed the cord running down her back—unless it snagged on a doorknob or a piece of equipment.

|

Orascoptic's Freedom LED head lamp clips on to any TTL loupe. Battery packs that hook onto the arms can support six hours of work. A touch switch turns the light on and off with the back of the hand. |

The cordless Freedom LED head lamp from Orascoptic provides enhanced visibility in combination with loupes. The goal for Orascoptic was to improve vision for dentists and hygienists examining, diagnosing, and treating dental work. (Check out a promo video about Freedom LED.) The device was designed by Bjorksten | bit 7 (Madison, WI).

The head lamp weighs 7 oz. and clips on to any through-the-lens loupe. The lightweight unit features rechargeable battery pods that securely fasten to the loupe’s temple arms. The battery pack is unique in that it helps to balance the lamp off the user’s nose. “The balance is very impressive,” says juror Craig Jackson, PhD, the retired president of Hemosaga Diagnostics Corp. (San Diego). The pod system charges quickly and provides 6 hours of energy life. It also eliminates the cord and pocket battery pack used in some head lamps.

Another feature that caught the jurors’ attention was how the unit deals with light switching. In most head lamps, push buttons or toggles control the lighting. In the Freedom, the designers decided to use a capacitive touch switch that can be operated by the back of a user’s hand. “The capacitive touch switch is brilliant,” says juror Stuart Karten, founder of Stuart Karten Design (Marina Del Rey, CA).

The touch switch improves work efficiency in that the dentist does not need to set down an instrument to turn on or adjust the LED headlamp intensity. It also improves hygiene because finger surfaces that work on a patient don’t touch the device.

|

Compass modular furniture from Herman Miller Healthcare is designed to fit into any space in a hospital, clinic, or work room. Each panel is coated with Durawrap to enable easy cleaning. Additional design details keep spills and splashes from seeping into cabinetry. |

Compass: The Smartest Furniture in the Room

Wood, steel, PET, and aluminum are the components of Compass, a modular system of interchangeable cabinets and workspace that can be used to create applications for patient rooms, caregiver work areas, and other clinical spaces. But the cost-effective materials, 58% of which are recycled, are only one part of this well-thought-out system. Submitted by Herman Miller Healthcare (Zeeland, MI), Compass is designed to accommodate change, as well to cut costs for hospitals and contribute to patient comfort. The Herman Miller Design for the Environment team applied environmentally sensitive design standards, using the McDonough Braungart Design Chemistry Cradle to Cradle design protocol.

The Compass system is composed of horizontal mounting rails that attach directly onto the architectural walls of a patient room, exam room, or workspace. Vertical stiles attach to the rails and support the various tiles and storage components. Tiles and components are wrapped in Durawrap, a 99.9% PVC-free material that requires no edge banding, resulting in a seamless, cleanable, and durable surface.

“There are thoughtful details, down to insulation and cleaning procedures,” explains juror Sean Hägen, founder of BlackHägen Design (Dunedin, FL). Such attention to detail is largely a result of dedicated research. The design team conducted interviews with more than 550 clinicians, facility administrators, healthcare architects, and designers to determine their needs and the most important features for a system.

Researchers found that cleanliness was the most important requirement in the system's design. In addition to the Durawrap, tiles are designed to overlap in the horizontal plane to allow liquids to run down from one tile to the other. Liquids can’t gather in corners or hide between seams. In addition, the design mount floats above the floor, providing additional access to clean spills. Horizontal work surfaces are designed to allow liquids to drip to the floor for easy cleaning, and even the sink was designed with a raised lip to reduce splashing. “They have comprehensively covered maintenance issues, including spills and fluid management,” notes juror Anne Miller, an assistant professor at the Vanderbilt University Medical Center (Nashville, TN).

Besides having a clean surface, it was important to designers that the system looks clean as well. “The system dramatically reduces visual clutter, which translates into less stress for both patients and caregivers,” says juror Bryce Rutter, founder and CEO of Metaphase Design Group (St. Louis). Compass is designed and engineered to optimize the ergonomics for both the patient and the caregivers while providing a warm, healthcare-appropriate, and reassuring environment.

The modular design allows nurses and other clinical staff to make real-time changes to the patient room environment in response to changes in supply storage, patient acuity, or EMR introduction. These changes can be made with little downtime and without sending anything to a landfill.

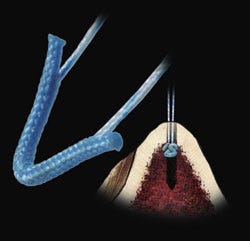

JuggerKnot: Refining Tissue-to-Bone Connections

Various athletic injuries can result in soft tissues being torn from their original insertion site on the bone. The soft tissue repairs that occur adjacent to the articulating surfaces of a joint present a challenge because any aspect of the procedure that damages these surfaces can have devastating consequences to the patient. Minimizing the collateral damage and risks created by a repair is one of the primary goals of the JuggerKnot Soft Anchor. The JuggerKnot, created by Biomet Inc. (Warsaw, IN), is used during arthroscopic surgery or in sports medicine surgeries. The surgeon uses the suture to tie tissue to the bone.

|

The JuggerKnot from Biomet Sports Medicine aims to tie soft tissue to bone without causing additional articular damage. To do so, it replaces a bone screw with a suture, minimizing the drill hole size while creating a strong anchor. |

To understand the advance of the JuggerKnot, we must first understand the standards of care that preceded the design. Several years ago, it was standard practice to create through-holes in the bone and suture tissue through those holes. But the technique posed a risk to neurovascular structures in addition to being time-consuming and complex. Suture anchors were then created as a means to connect suture to the bone without having to drill completely through the bone. These early anchor screws measured 3 mm in diameter and were made from stainless steel. The large size weakened bone structure and could cause collateral damage to other structures if the screw became dislodged. The drilled holes could also cause articular surface damage to the bone. Even after new materials were adopted such as PLLA, PGA, and PLDA, a lost anchor could damage articular cartilage, which could cause pain and early arthritis.

Biomet has changed the game with JuggerKnot, which uses a new technique that sutures soft tissue to bone with a suture instead of a screw. “This is novel engineering,” observed juror Clay Burns, who is vice president at Smart Design (New York City). “It places emphasis on cost efficiency and simplicity.”

A 1-cm strand of suture is combined with a standard suture used to tie down tissue passing through it along its central axis and stuffed into a small hole drilled in bone. Pulling back on the free strand of suture causes the smaller suture to bunch up, increase in diameter, and press against the rough wall of the bone hole.

Its simple design enables a 1.4-mm drill hole to be used thereby conserving a patients bone structure and reducing the risk to adjacent structures. Further, there are no eyelets or internal features to break, which means that the JuggerKnot anchor is stronger than previous anchor designs. Juror Peter Denk says: “It’s easy to use and has good bone interaction to promote healing.” The suture sleeve provides a low friction, soft, edge-free geometry for the tying suture to reside against, so failures due to suture breakage are mitigated.

An added benefit is that even if the anchoring sleeve were to pull out of the bone, it is made of suture, the same material already in contact with articular surfaces. It is therefore much less likely to damage such structures.

|

Coloplast A/S successfully juggles brand awareness and discretion with its SpeediCath Compact Male. The catheter is easy to carry, use, and dispose of. |

SpeediCath: Discretion in All Things

Urinary catheters are not easy to live with or to design. They are difficult to conceal, awkward to store and carry, and take up space in the home and in transit. Enter the SpeediCath Compact Male from Coloplast A/S (Humlebæk, Denmark), a small, discreet, and sterile catheter that can be used in the home and on the go. It is less than half the size of a standard catheter and it features hydrophilic coating to reduce friction during insertion and removal.

The Coloplast design team created a catheter that fits into a patient’s pocket, has easy-to-open packaging, and can be disposed of conveniently.

“Design and engineering got it right,” Burns says. “This has tricky tooling and a good feel for parts and brand.”

Challenges for the company included choosing the right materials—a thin material that could withstand injection molding over a relatively long distance and accommodate simple manufacturing techniques. It also required considering the company’s existing branding message—Coloplast has a female catheter design already on the market.

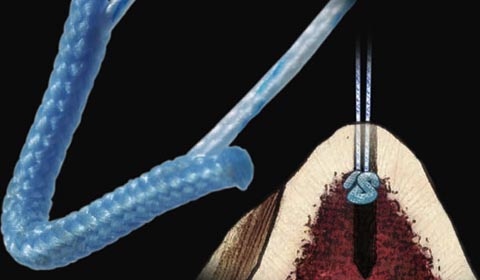

PleuraFlow: Enacting the Laws of Simple Attraction

Much like the JuggerKnot’s simple and effective engineering, the PleuraFlow system struck a similar “Well, why didn’t I think of that?” note among the MDEA judges. The PleuraFlow catheter system from Tucson, AZ–based Xeridiem Medical Devices (formerly MRI Medical) is used during open surgical procedures and trauma (e.g., cardiothoracic procedures) to prevent fluid accumulation within the operative site after closure of the surgical wound. It is a tube clearance apparatus intended to prevent clogging and occlusion of chest tubes used for pleural and mediastinal drainage. Physicians insert and position the device into patients’ pleural space after thoracic surgery. It aims to solve the problem often met with postsurgical drainage. Research shows that patients think that the worst part of their chest surgery is the pain caused by having large tubes sticking out of their chest.

|

The PleuraFlow catheter system works to improve patient comfort and outcomes while reducing the burden on clinicians. Xeridiem Medical Devices' postsurgical tool removes clogs in chest tubes using magnets and other unique design elements. |

The system comprises a curved silicone chest tube measuring 20 FR (less than 40% the size of standard chest drainage tubes) and a guide tube that is connected to a drainage canister. Inside the guide tube is a magnetically driven guide wire that advances into the chest tube. The wire can be advanced and retracted with in the chest tube to break up and remove tube obstructions or clogging.

Designing the curved device meant meeting various challenges, particularly how to advance the inner clearance wire to pull out clots. The magnet-driven system drew praise from several jurors. “The curved chest tube naturally adapts to anatomy and the magnetic mechanism is smart and unique,” explains juror Mary Beth Privitera, assistant professor at the University of Cincinnati.

The smaller incision contributes to patient recovery and reduces nursing care needs. Nurses were often required to squeeze out excess clogged fluids, a process that proved to be ineffective and cumbersome. The PleuraFlow claims to improve patient care and provide a better tool to clinicians for removing clogs postsurgery. Patient comfort is increased and the burden on medical staff is reduced. “It’s a simple idea that solves a complex problem,” says juror John Sinacori, an assistant professor in the department of otolaryngology at Eastern Virginia Medical School (Norfolk, VA).

Conclusion

Patients and users will never notice the details that have occupied the days and nights of the design teams that created devices singled out by MDEA jurors as examples of excellent design, and that is the point. If manufacturers pay attention to details, it means that users don’t have to. With the details out of the way, doctors, nurses, and other practitioners can give their full attention to treating patients, enabling them to concentrate on accelerating healing, improving quality of life, and decreasing pain.

Heather Thompson is editor-in-chief of MD+DI.

About the Author(s)

You May Also Like