November 23, 2010

|

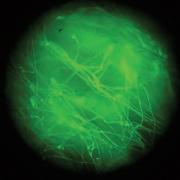

A green fluorescent protein attached |

From marshaling bacteria to grow silk proteins to replicating silk produced by honeybee larvae, the manipulation of natural silk has emerged as a promising approach for healing wounds, fabricating sutures, and repairing damaged tissue. Adding to the buzz is a team of researchers from academia and industry that has succeeded in genetically modifying silkworms so that they can spin spider silk. Their labors could lead to the development of a commercially viable native silkworm silk with the legendary strength of spider silk.

Although silkworms have been harvested for centuries, their native silk is too weak for many medical applications. In contrast, spider silk is stronger than steel and more flexible than Kevlar. However, it is not available in large quantities, nor is there an economically viable means for purifying it so that it can be polymerized and spun into strands.

Facing this conundrum, Kim Thompson, CEO of Kraig Biocraft Laboratories Inc. (Lansing, MI), asked Malcolm Fraser, a professor of molecular biology and genetics of viruses at the University of Notre Dame (Notre Dame, IN), whether silkworms could be used to purify and polymerize spider silk. "That was a 'Yeah, sure,' moment for me," Fraser recounts. "Silkworms are effectively a protein bioreactor platform. You can make virtually any protein of choice in the silkworm, or you can modify the silk itself to have whatever properties you would like."

The key to producing this transgenic silk is piggyBac, a sequence of DNA known as a transposon that can insert itself into the genetic machinery of a cell. "PiggyBac is a transposable element," explains Fraser, who holds a patent on this technology. "For several years, we've been defining its characteristics in terms of movement and its ability to be used as a gene vector to carry genes into the genome of many, many species."

While using piggyBac to engineer spider silk into silkworm silk, Fraser's team attached a green fluorescent protein to the spider silk protein to observe whether the two silks had chemically bonded. The success of this test convinced them that the resulting material was not simply silkworm silk with an admixture of nonintegrated spider silk. "It was actually a composite structure," Fraser adds.

The engineering of the additional sequence for encoding the green fluorescent protein also demonstrated that many other protein sequences could be added into the structure of the spider/silkworm composite silk. "Our vision is that some of the protein sequences that we can incorporate will be peptide hormones or growth factors that can stimulate the growth of particular kinds of cells and speed wound healing or reduce scar tissue formation during wound healing," Fraser says. For burn victims, he envisions making a silk-fiber mat that stimulates the growth of normal skin rather than scar tissue.

To convert the transgenic silk into medical products such as ligament scaffolds, however, manufacturers must be able to fabricate it in commercial quantities and manipulate it into threads with the appropriate diameters. "A lot of post-genetic-engineering manipulations will be needed," Fraser notes. "But since silkworm silks have already been used in some surgical applications, the FDA shouldn't have a big problem with the subtle modifications we're making. Thus, genetically modified silkworm silk should be easily available in five to seven years."

You May Also Like