February 1, 2007

NEWS TRENDS

|

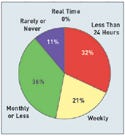

Less than one-third of medical device companies show their employees results within 24 hours, thus many daily meetings are not looking at recent issues. |

A research firm has completed a study that found that medical device companies that have manufacturing execution systems (MESs) are more likely to improve in most financial and business metrics than those that don't.

Industry Directions (Cummaquid, MA) concluded that a plantwide MES improves company performance in a number of ways. An MES gives a firm more data from production to determine how or where to make improvements and replaces less-efficient paper systems. It is also an effective tool for device history record recording and reporting and ensures compliance with best practices. The study was funded by Camstar (Charlotte, NC), an MES provider.

Of the device companies that responded to the survey, one-third had such systems, and all of them had gained market share in recent years. Of the two-thirds that did not have an MES, only one-third had gained market share.

“Medical device manufacturers have an opportunity to grow at a nearly unlimited rate, but most are stymied by a lack of speedy, accurate information from their production processes,” said Julie Fraser, Industry Directions' lead analyst, in a statement. “As a result, the market cap for these companies does not look nearly as healthy as their profit margins suggest they should. Increased investment in plant software systems will be a cornerstone of medical device companies' ability to measure and improve performance as well as grow.”

Firms using an MES also showed greater performance than those that don't in metrics such as earnings before interest, taxes, depreciation and amortization; economic added value; revenue per square foot; yield; overall equipment effectiveness; and overtime reduction.

A major benefit that an MES brings to the table, the report found, is speed. Firms without an MES often cannot determine the key performance indicators of their manufacturing operations within a time frame fast enough to take action. But operations personnel at firms with an MES can see results from key performance indicators fast enough to change course and maximize performance (see figure on page 20).

An MES also improves the speed and accuracy of data collection by automating the process, the study found. In that way, it reduces the opportunity for data-entry error and for word-of-mouth mistakes that are never formally reported and can get repeated.

Copyright ©2007 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like