MD&M Minneapolis 2011 Event Coverage

October 13, 2011

Colin Weightman, director of technology at Comco Inc. (Burbank, CA), will present "Making Better Cardiac Devices with Microblasting" at the MD&M Minneapolis Innovation Briefs Theater on Thursday, November 3, at 2:45 pm. Comco Inc. specializes in microabrasive blasting technologies for the medical device industry, among others.

MPMN: What topics will be discussed in your presentation? Weightman: Titanium alloys are used extensively throughout the medical device industry because of their high strength-to-weight ratio. Specifically in the cardiac area, nickel-titanium alloy, or nitinol, is used as a foundation for many devices. Common devices for which the alloy is used include AAA stent grafts, minimally invasive heart valves, and other structural components.

Weightman: Titanium alloys are used extensively throughout the medical device industry because of their high strength-to-weight ratio. Specifically in the cardiac area, nickel-titanium alloy, or nitinol, is used as a foundation for many devices. Common devices for which the alloy is used include AAA stent grafts, minimally invasive heart valves, and other structural components.

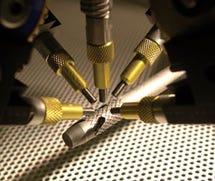

Nitinol provides several benefits for these applications, but it is perhaps most notable for its superelasticity and durability. The microblasting process can help to improve the surface and structural characteristics of nitinol, however, thereby increasing device durability. These improvements are made through controlled erosion of artifacts on the device surface, the generation of specific surface finishes for postprocessing and integration, and the micropeening of the surface to increase fatigue life.

MPMN: How can microblasting contribute to better cardiac devices?

Weightman: Medical implant devices fabricated using laser machining and stamping of nitinol often contain minute defects and blemishes as a result of the manufacturing process. If left untreated, these imperfections will adversely affect the performance, as well as the life span, of the device. Microblasting the device removes discoloration and oxide layers from the surfaces. It also smoothes laser pulse marks and sharp edges, as well as laser slag. Finally, it decreases the propensity for microcracking.

MPMN: Why is this information important for medical device OEMs to know?

Weightman: Many manufacturers are familiar with microblasting's distant cousin, grit blasting, and have little idea of the precision that is possible with a microblasting system. For example, we had a customer come to us with a new application for controlled erosion on a substrate, removing material within a tolerance level of less than 1 ?m. The customer didn't really expect that we could do this and was very surprised when we showed that we could. We find that many engineers are amazed that we can actually remove a material to a tolerance of less than a micron, or, without masking, texture a surface with a transition of 0.007 in. between the fully textured surface and the untouched surface.

You May Also Like