May 1, 1998

Machining

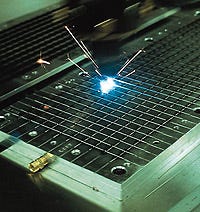

Laser System Incorporates Direct Beam Delivery

Spot-beam focusing capability permits fine cutting and drilling

A LASER MACHINING SYSTEM originally engineered for integration with fiber-delivered lasers for welding has been enhanced with direct beam delivery capabilities. Direct beam delivery, which enables beam focusing to smaller spot sizes than is possible with fiber delivery, expands the applications of lasers to include fine cutting and drilling.

Developed by Lumonics (Kanata, Ontario, Canada), the Laserdyne Model 140 uses precision mirrors and optics to direct the laser beam to the workpiece and focus it on a precise spot with a diameter of 0.001 in. or smaller. Product manager Terry VanderWert says that "this is essential for intricate cutting and drilling applications."

The system features a three-axis Class 1 laser workstation and a powerful Laserdyne 94/PC laser process control. An optional rotary table enables the processing of 3-D parts. Digital signal processors and a high-speed serial bus provide 200-microsecond servo update time for quick and accurate multiaxis motion.

The x- and y-axis travel is 12 in., while z-axis travel is 6 in. An optional rotary axis provides continuous rotation for applications involving circular parts and tubing. X- and y-axis accuracy is ±0.001 to ±0.0002-in. full travel, achieved by using linear encoders and laser interferometer calibration. Z-axis accuracy is ±0.005 in. Repeatability is within 0.0005 to 0.0002 in. for the x-and y-axes, within 0.005 in. for the z-axis, and within 20 arc-sec for the rotary axis. Load capacity is 100 lb for the x- and y-axes, and 50 lb for the rotary axis.

All laser, motion, and process parameters can be controlled from the keyboard or from within the part program. Programming features include variables, subroutines, beam radius compensation, character generation, and axis and plane rotation.

Filtration

Filter Ensures Delivery of Sterile Gas

Maximizes use of its membrane surface while maintaining a hydrophobic barrier

A FILTRATION DEVICE has been specifically engineered for sterile gas delivery in healthcare applications.

Pall Gelman Sciences (Ann Arbor, MI), a manufacturer of filtration and separation products used in healthcare, diagnostic, and laboratory research applications, recently developed the Intervene filter to handle gases filtered at extremely low pressures, providing complete use of the filter membrane's surface while maintaining a hydrophobic barrier. This allows maximum air/gas-flow rates with minimal pressure drop while protecting equipment from exposure to fluids. The result is consistent end product performance.

The rectangular, low-profile housing design incorporates an effective filtration area of 18.5 cm2 of PTFE membrane or a proprietary hydrophobic glass media. Connection options include 1/4-in. hose barb or 3/8—1/2-in. stepped hose barb connectors. Typical uses for the Intervene filter are in insufflation, blood oxygenation, vacuum protection, and oxygen concentration applications. Custom printing is also available.

Uv Curing

Bonding Technique Yields Rugged UV Lamp

Can be used to cure adhesives or sterilize devices

USING A PATENTED TECHNIQUE for bonding sapphire to metal seals, a company developed a linear sapphire lamp that can tolerate very high operating temperatures (2050°C), enabling shorter processing and curing times. It also permits high lamp-operating temperatures and high power levels of lamp loading.

By bonding sapphire to metal seals, Xenon Corp. (Woburn, MA) eliminated a potential weak point—the seal between metal and nonmetal—and developed a lamp of high-quality construction and performance.

A manufacturer of standard and custom-designed pulsed- and continuous-wave UV curing and processing systems, Xenon uses this innovative sapphire-to-metal bonding technology to produce lamps that provide numerous benefits. According to the company, the fine optical properties of sapphire provide better wavelength transmission than do traditional quartz envelopes, and its strength offers safety advantages during lamp handling and mounting to equipment. Sapphire lamps are suitable for such applications as lasers, UV curing systems, and pulsed-light sterilization.

Sapphire lamps transmit from 140 nm of deep UV through 7800 nm in the far infrared. Heat transfer is up to 27 times faster than quartz, and operation at higher power levels for longer periods of time is possible. As a result, sapphire lamps can help reduce production costs and labor time.

Designed as an integral part of fast-acting curing systems, the lamps can also be used as replacement bulbs.

You May Also Like