January 12, 2010

|

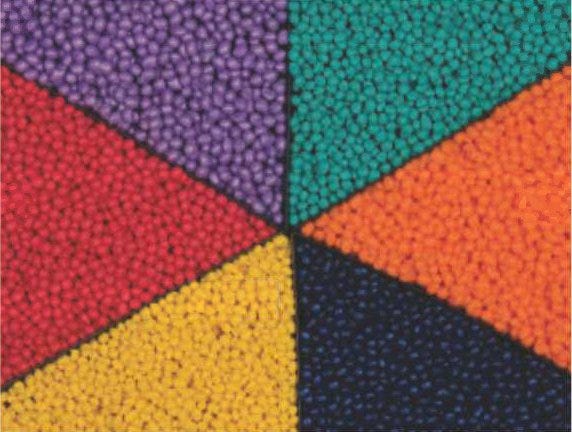

Kraiburg has developed the Thermolast M line of TPEs for use in a variety of medical products. |

It seems only natural that a German supplier of thermoplastic elastomers (TPEs) would serve the automobile industry. But when Kraiburg TPE Corp. (Duluth, GA) diversified into the personal care industry, lending its TPEs to razor components and toothbrushes, it paved the way for a host of new opportunities. Because some such applications require FDA-approved materials, Kraiburg identified the potentially lucrative medical device industry as a natural next step for the business. Now, with its new medical TPE series, Kraiburg is making the leap from razors to respiratory masks in an effort to make the cut in the medical device market.

Long before razors and respiratory masks, however, Kraiburg was founded as a manufacturer of rubber compounds in 1940s Germany, focusing on traditional thermoset rubbers following World War II. After enjoying several decades of steady work, the company set the wheels of change in motion by launching a TPE business in the 1980s, specializing in styrenic TPEs. With this new initiative, Kraiburg began to diversify not just industry markets served, but also geographic markets. On the heels of opening up to a broader European client base, the company forged a sales relationship with the U.S. market in 1999, produced materials in its Georgia plant beginning in 2002, and recently opened the doors to a facility in Asia.

With a foot in the U.S. market and its eye on the medical device industry, Kraiburg will be exhibiting at MD&M West this year for the first time. "We've decided to use MD&M West as a launching pad for our effort in the medical market," notes Jeff Frankish, managing director for the Americas of Kraiburg TPE. The company's primary objective at the show will be to promote Thermolast M, its newly launched family of TPEs optimized for use in medical products.

"[The materials] are still based on the styrenic TPE technology that we've historically been developing and focusing on; but, what we've done differently with this particular family of products, is that all of the compounds we've developed are geared more toward overmolding applications," Frankish says. "All of the compounds we've developed for this portfolio are tested and listed in [FDA's] Drug Master File, so we have some certification process in place," he adds.

Boasting quality initiatives such as USP Class VI compliance and ISO 10993 certification, the Thermolast M materials also are designed with the advantages of being sterilizable, highly elastic, and free of latex and PVC. Suitable for overmolding or injection molding operations, the family of products can be employed in a variety of medical applications, including facemasks, packaging, drip chambers, and components such as sealers, stoppers, connectors, and gaskets.

"Our target with these materials is to try and displace some of the more-traditional medical or silicone rubber materials used," Frankish comments. He points out that thermoplastics processing typically has faster cycle times than a traditional thermoset, and often eliminates the need for various secondary operations, such as trimming flash off of parts or curing materials.

In addition, Kraiburg's Thermolast M materials are manufactured on a dedicated compounding line in the company's German facility. The materials are also supported in another unique way: Kraiburg has agreements with its raw materials suppliers to ensure safety and consistency for medical device OEMs. "We have an obligation as we work with some of the major medical and pharmaceutical companies, and if we are notified by a raw materials supplier that we need to discontinue raw materials or change, they're committed to us to deliver at least 24 months of stability in terms of delivering the same raw material until we have an opportunity to qualify an alternative raw material," Frankish explains. "So, that provides a unique service and safety package for OEMs."

Kraiburg TPE Corp.

www.kraiburg-tpe.com

Booth #1493

You May Also Like