June 6, 2009

|

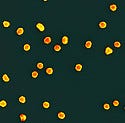

Gold nanoparticles (shown above) gain stability when encapsulated in graphene. |

Gold nanoparticles have been identified by researchers as critical components in the development of next-generation medical applications, including novel new controlled drug-delivery methods, cancer-destroying technologies, and diagnostic devices. To achieve progress in some of these areas, however, scientists must first determine how to increase the stability of these noble nanoparticles and produce them in large quantities. Researchers at the University of Alabama (UA; Tuscaloosa, AL; www.unix.eng.ua.edu) and the University of Kentucky (UK; Lexington, KY; www.uky.edu) may have found a solution.

Limitations of gold nanoparticles have centered on their lack of particle stability and tendency toward nonspecific binding. Although traditional methods of gold nanoparticle surface passivation--employed to improve stability--have relied on ligands, recent research has demonstrated that encapsulating nanoparticles in graphene shells could prove to be a better technique. Scientists have found that the carbon encapsulation method provides stability and facilitates functionalization of the nanoparticle.

"By making a robust passivation material, many of the challenges in the area of gold nanoparticles can be overcome," says Nitin Chopra, the lead researcher and an assistant professor at UA's Metallurgical and Materials Engineering Department. "These passivation layers should not restrict [gold nanoparticles'] optical properties--that's the biggest challenge with gold."

Researchers from various institutions have been experimenting with graphene encapsulation of gold nanoparticles. However, growth of carbon shells on the nanoparticles has, until now, only been accomplished through carbon deposition during transmission electron microscopic analysis, which yields sample-size quantities. The UA-UK team, on the other hand, has been able to take the carbon encapsulation of commercially bought gold nanoparticles to the next level through the development of a fabrication process capable of producing the quantities needed for real-world applications.

Uniformly dispersed and plasma-oxidized gold nanoparticles on chemically modified silicon substrates serve as catalysts for carbon cultivation. Enabling graphene shell growth on the surface-oxidized nanoparticles is the use of a chemical vapor deposition (CVD) process, which is a unique aspect of this fabrication method, according to Chopra.

Chopra also notes that by varying CVD processing time, the researchers can control the thickness of the shell. They found that longer exposure to CVD processing created thicker shells while shorter durations produced thinner shells. "We make the shell very thin, but expect to still retain the optical properties of the gold," Chopra adds. Ultimately, the scientists determined that the duration of the CVD growth process should be fewer than four hours in order to avoid sample degradation.

Now able to produce sizable quantities, the researchers' next step is to make the process scalable. By doing so, they believe that the encapsulation of gold nanoparticles in graphene could be used for bioanalysis and medical sensing applications.

Copyright ©2009 Medical Product Manufacturing News

You May Also Like