October 1, 1999

Machinery

Extruders Meet Many Needs

Series offers new benefits

Enhanced extruders bearing the Prodex name are available in screw sizes ranging from 2 to 10 in. Made by HPM Corp. (Mount Gilead, OH), the series includes the Prodex I extruder, which features 24:1 L/D, air-cooled bimetallic barrels with a choice of screws; the Prodex II, offering longer L/D ratios and available with either air or water barrel cooling and vented barrels; and the Prodex III, available with screw diameters up to 10 in. and barrel L/D ratios up to 50:1.

Prodex extruders are designed to offer processors several key benefits. These include high speeds (in some cases up to 800 rpm), excellent mixing and dispersion, fast changeovers and color changes, and the ability to maximize output and production rates.

All machines feature standard bimetallic barrels and are available with a choice of Double Wave or Triple Wave screws for optimal performance. The machines are also designed to produce higher outputs at lower temperatures than their predecessors.

For more information, call HPM Corp. at 419/946-0222.

Materials

Composite Aimed at Bushings, Bearings

Lubricant compound a key ingredient

This composite material, developed specifically for high-load bushing and bearing applications, is the latest version of the XC-2 material developed by EGC Corp. (Houston). XC-2L is a carbon-fiber-reinforced composite with a special lubricant that, the supplier believes, makes it one of the few dry-running-capable materials on the market.

The material is designed to replace metal and other thermoplastics in bearing applications such as valves, pumps, and other industrial process equipment. By providing continuous lubrication, the material reduces the chance that critical equipment will seize or gall. And its PEEK matrix makes it highly resistant to most chemical processing fluids.

In comparative testing, XC-2L exhibited only half the wear of carbon at 12,000 PV against condition 1075 stainless steel 17-4 PH, according to the manufacturer. Under similar test conditions, the material's wear rate was 700 times lower than that of bronze, the company claims.

For more information, call EGC Corp. at 800/342-7677.

Motion Control

Motion Controller Offers High Processing Speeds

Works with all motor types

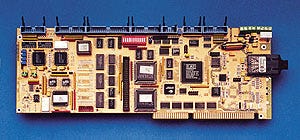

A programmable motion controller, the PMAC2-PC Ultralite is a multiaxis device that can commutate and control all motor types (brush and brushless dc, ac vector, stepping, and switched reluctance) in precision velocity and position motion systems. Manufactured by Delta Tau Data Systems (Chatsworth, CA), the device offers high processing speeds and resolution capability of 40 MHz in the standard version and 60 and 80 MHz in the higher-speed optional versions. Servo update time is 18 microseconds per axis.

The motion controller is combined with the Macro fiber-optic ring network interface, which has a data rate of 125 Mb/sec. This high-speed network eliminates the need for the local-axis interface circuitry found in other members of the same family of motion controllers. (The name "Ultralite" is meant to signify the absence of these onboard axis interface circuits.)

As with other members of this product family, the PMAC2-PC Ultralite board may be installed as a stand-alone device, which will execute motion programs and completely control a machine's operation.

For more information, call Delta Tau Data Systems at 818/998-2095.

Hardware Accessories

Couplings Tackle Challenging Applications

Some feature an automatic shutoff valve

Made of economical acetal, APC-series couplings are available with an automatic shutoff valve to eliminate wasteful or potentially dangerous spills during disconnection. The couplings, made by Colder Products Co. (St. Paul, MN), are designed for use in challenging fluid-handling applications, including cooling and lubricant lines, mild-chemical handling, laboratory tubing, and water filtration.

Offering a 1/4-in. nominal flow capacity, the couplings feature the CPC thumb latch, which provides simple, intuitive operation and an audible "click" to verify a secure, leak-free connection. APCD couplings, which offer the automatic shutoff valve, have a shrouded clip to protect against accidental disconnects.

All APC couplings include Buna-N O-rings, 316-stainless-steel valve springs, and integral fittings that are supposed to cut installation time and eliminate leak points. APC bodies come in NPT, BSPT pipe thread, and in-line styles with 1/4- or 3/8-in. hose barb, pipe thread, or compression terminations. Insert styles are available in hose barb, pipe thread, or compression terminations with elbow or in-line configurations.

For more information, call Colder Products Co. at 800/945-3814.

Copyright ©1999 Medical Product Manufacturing News

You May Also Like