March 2, 2011

|

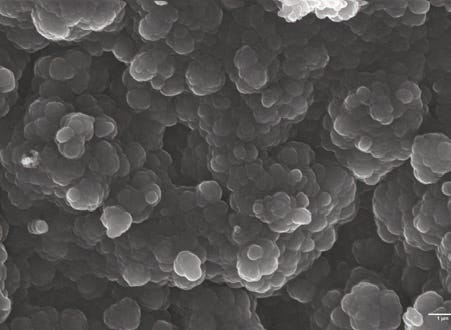

Polypyrrole electrodeposited on conventional titanium releases drugs on demand from the surface of implantable devices. |

The risk of bacterial infection and inflammation associated with a host of implantable devices is impelling the medical device industry to develop in situ drug-delivery technologies that can ensure long-term implant viability. Contributing to this effort is a team of researchers at Brown University (Providence, RI), which has demonstrated the feasibility of a drug-releasing sensor that can be grown directly on the surface of implantable devices.

"Pills or systemic methods for treating implant-induced infections have proven ineffective to date," says Thomas Webster, associate professor of engineering and orthopedics at Brown. Believing that the most effective way to treat implant-related infection or inflammation is from the implant surface itself, Webster and his colleagues have developed an implant sensor that releases drugs on demand when it is stimulated by electrical fields.

To fabricate the sensor, Webster's team begins by growing nanopores on an implant substrate material such as titanium. Then, they use chemical vapor deposition to grow carbon nanotubes out of the nanopores. "The carbon nanotubes are grown so that they can protrude from the implant surface, enabling them to electrically sense what type of cell has attached itself to the implant and what type of tissue is forming," Webster explains. "Since bone has a different conductivity than bacteria and inflammatory cells, we can use the carbon nanotubes to measure such conductivity and determine these biological events."

After creating the nanotube sensor on the implant's surface, the team coats it with drug-loaded polypyrrole, a conductive polymer that can be electrochemically synthesized on conductive materials. By means of the carbon nanotubes, this polymer is electrically stimulated to release the desired drugs. "In this way, we have created a sensor on an implant that can first determine biological events and then control them," Webster notes.

The number of electrical pulses the polymer receives determines the type of drug that is released, according to Webster. "When we load antibacterial drugs into regions of the polymer that are less dense, a few pulses stimulate the polypyrrole to release drugs to decrease infection. In contrast, if we load anti-inflammatory drugs into regions of the polymer that are more dense, many pulses are needed." Selective stimulation can also be used to release anti-inflammatory agents in implant regions that are more susceptible to inflammatory responses.

In vitro studies have shown that the implant sensor can determine what type of tissue--such as bone, biofilm, or scar tissue--is growing. The research team has also demonstrated that the sensor can regulate drug release on command to control such cell responses as bone growth, fibroblast functions, biofilm formation, and inflammation. "Pretty much any type of drug can be incorporated into the polypyrrole," Webster says. "We have used penicillin and gentamicin as model antibacterials and dexamethasone as a model anti-inflammatory."

You May Also Like