Buckeye Shapeform customized an enclosure for the control unit of a device designed to optimize radiation treatment for lung cancer patients

October 13, 2011

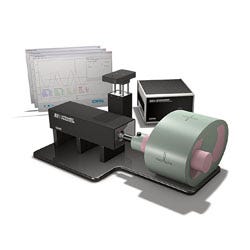

Designed to simulate the body of lung cancer patients, the Dynamic Thorax Phantom provides a comprehensive analysis of imaging acquisition, planning, and dose delivery in image-guided radiation therapy. In the process of developing such a novel device, manufacturer Computerized Imaging Reference Systems Inc. (CIRS; Norfolk, VA) enlisted the aid of engineering firm BBG Inc. (Chesapeake, VA) and Buckeye Shapeform (Columbus, OH).

|

Buckeye Shapeform was able to develop a cost-effective, custom enclosure to house critical components of the control unit for a patient simulation device. |

A quality assurance tool for image-guided radiation therapy, the Dynamic Thorax Phantom enables medical physicists to localize and treat a simulated tumor while accounting for natural patient respiratory motion during radiation therapy. By simulating the natural movement of the body, the device helps to ensure that the correct dose of radiation can be accurately delivered to the patient. Consequently, it can also help to reduce the risk of exposing healthy cells to radiation.

Integral to achieving this simulation is the device's control unit. The critical component can take data recorded from the lung cancer patient's actual movements and then simulate those movements on the Phantom. In addition to performing this essential function, the control unit must be able to withstand repeated use in a harsh clinical environment. Seeking a custom enclosure to house the unit's components that met these requirements, contract engineering firm BBG reached out to Buckeye Shapeform for help.

"Not only did we need the most cost-effective way to house the device's sensitive controls, but we needed a one-stop shop that could handle all the enclosure customization," says Jim Black, president and senior engineer at BBG. "We knew that Buckeye Shapeform had an excellent reputation for their ability to customize enclosures, so we selected them to handle all the customization instead of subbing out the different aspects of customization to separate shops."

To achieve the desired result, the companies opted to customize Buckeye Shapeform's existing DII case. In addition, Buckeye Shapeform reworked the customization process for the case. Whereas previous versions of the control unit were anodized by one company and then sent to another company to punch holes in the case, Buckeye Shapeform combined both steps under one roof and reversed the order of operations.

"The reversal of the process--completing all modifications first and anodizing last--effectively eliminates potential weakening of the enclosure due to postanodization modifications," notes Carl Estock, Buckeye Shapeform project manager. "Reversing the process and completing all the customization under one roof seem like such little things, but they go a long way toward delivering a higher-quality, more cost-effective product for the benefit of lung cancer patients receiving treatment with the help of the Dynamic Thorax Phantom."

Black of BBG adds: "Buckeye Shapeform has handled every job we have given them with expertise and professionalism. Their enclosures help make our products successful, which, in turn, have a crucial impact in the lives of lung cancer patients."

You May Also Like