January 1, 1998

HOTLINE

Surface Treatment

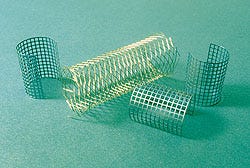

Coating Minimizes Thrombosis and Restenosis in Cardiovascular Stenting

Prevents adsorption of potentially thrombogenic proteins

A SURFACE COATING developed by Advanced Surface Technology Inc. (Billerica, MA) has the potential to minimize the thrombosis and restenosis that commonly occur in cardiovascular stenting. It may also serve as a suitable coating for other implantation procedures that face similar biocompatibility challenges.

BioLAST is a nonthrombogenic biocompatible coating that, when it comes in contact with physiological fluids containing albumin, selectively and reversibly binds the endogenous albumin. Subsequently, the albumin prevents chaotic adsorption of denatured and potentially thrombogenic proteins. Additional benefits include reduced platelet adhesion and activation and inhibited microbial adhesion.

Advanced Surface Technology is an ISO 9001certified company offering a variety of proprietary coating and surface modification technologies to the medical device industry. These include the LubriLAST hydrogel coating, which enhances the surface lubricity of such devices as catheters, drainage tubing, and guidewires; the HydroLAST surface treatment, which creates a highly wettable surface on polymeric porous materials and fabrics; and ParyLAST, a combination of the company's cold plasma surface modification technology and a parylene conformal polymeric coating. Coatings can be applied to devices on a contract manufacturing basis or licensed on a tech-transfer basis.

For more information, contact Advanced Surface Technology Inc. at 978/663-7652.

Rapid Prototyping

Service Bureau Uses New 3-D Printing System to Create Prototypes

Parts can be created faster than with other technologies

SANTIN ENGINEERING INC. (Peabody, MA) has become the first service bureau to offer prototypes using a new 3-D printing system.

Developed by Z Corp. (Somerville, MA), the Z402 system is especially useful for the creation of appearance models. These models can be used by industrial designers and product-development specialists in the early stages of product development to test concept designs, verify CAD files, or serve as 3-D product renderings to elicit feedback from focus group research. They can also be used as patterns for investment casting applications.

According to Santin, the Z402 system creates parts up to 20 times faster and at a lower cost than currently available processes. For example, a part with dimensions of 8 x 4 x 1 in. takes only 32 minutes. The system receives data from a CAD file and produces a 3-D model layer by layer using starch-based powders bound together by an adhesive. The technology, called the 3DP process, has been patented by the Massachusetts Institute of Technology and licensed for commercialization by Z Corp., which has developed the proprietary software that runs the system.

To build a part, the machine spreads a single layer of nontoxic cellulose powder onto the movable bottom of the build box. A binder is deposited onto each layer of powder to form the shape of that cross section of the CAD file. The bottom of the build box is then lowered by one-layer thickness (ranging from 0.005 to 0.009 in.), and a new layer of powder is spread until the part is complete. The unbound powder is then removed from the final part, which can then be impregnated with hot wax or other materials to add strength and finishability.

For more information, contact Santin Engineering Inc. at 508/535-5511. Contact Z Corp. at 617/628-2781.

New Software

Validation Software Developed for Medical Device Manufacturers

Standardizes documentation required by FDA

KMI SYSTEMS (Belmont, MA) has developed a software package to assist medical device manufacturers with the production of such complicated documents as validation protocols and engineering specifications. ValPro Intelligent Protocol Software is an easy-to-use database application that can improve documentation consistency and efficiency.

According to KMI Systems, ValPro can save as much as 40% of the validation costs of an individual project, and it allows users to standardize the documentation required by FDA for qualification. The software is also designed to allow users to take advantage of their own past work and legacy documents.

ValPro helps automate the production of validation protocols using a library of guidelines, test procedures, and data sheets. Users can rapidly create protocols by selecting and assembling test procedures from an extensive library of standardized tests or by creating (and saving for future use) their own new test procedures.

The software provides a change-history configurable option that creates a history file for each library object such as protocols and test procedures. With the change-history option enabled, the date, time, and user ID are automatically captured in the change history record, along with a user-supplied reason for the change.

KMI Systems is a division of Kemper-Masterson Inc., a company specializing in compliance and validation services. The division develops compliance and validation software for the pharmaceutical, biopharmaceutical, and medical device industries.

For more information, contact KMI Systems at 617/484-9920.

You May Also Like