May 24, 2009

Originally Published MPMN May 2009

MD&M EAST 2009: FIRST-TIME EXHIBITORS

Australian Firm Has Big Ideas for Medical Microtechnology

|

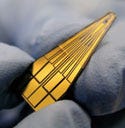

MiniFAB, a specialist in microtechnology and microfluidics, developed the osmolarity test card for the MDEA-winning TearLab system. |

When it comes to manufacturing miniature medical devices, design and development challenges can become significantly magnified. Luckily, there is an expanding handful of companies equipped with the niche know-how and capabilities in microtechnology to properly serve the medical industry in this capacity. Among them is MiniFAB (Scoresby, Australia), a company dedicated to the design, development, and manufacture of implants and diagnostic devices that include polymer-based microtechnology and microfluidics solutions.

Since it was established as a spin-off from the Industrial Research Institute Swinburne at Swinburne University of Technology (Melbourne, Australia) in 2002, MiniFAB has applied its core competencies in microtechnology, microfluidics, and nanotechnology to an array of implantable and diagnostic devices. Applications have included stents, catheters, electronic implants, endoscopic surgical implants, combination products, surgical tools and instrumentation, and point-of-care and laboratory-based diagnostic systems, including lab-on-a-chip products. More recently, the company has drawn on its microfluidics knowledge for cell and tissue handling and culturing.

Enabling this project diversity are extensive capabilities for the manufacture of micro-sized components with tolerances of 1% or less. "We found that there are very few, if any, players who are capable of integrating a large number of complex process steps to deliver a product that requires microtechnology and microfluidic features under [an] ISO13485:2003 regulatory umbrella," says Dusan Milojevic, MiniFAB manager, devices. "[The] majority of players specialize in one to two areas. Here, we have a long list of methodologies available." Included on this list are injection molding, electroforming, parylene coating, micromachining, embossing, testing, mask aligning, cleanroom manufacturing, lithography, nanoimprint lithography, and polymer processing.

Polymer processing has become an increasing focus of the company's attention due to the company's belief that silicon-based microtechnology has distinct limitations in medical applications, according to Milojevic. "While MiniFAB still has 'classical' MEMS capabilities, today only 10% of its business is based on silicon processing, with the rest coming from microtechnology processing of polymers," he says.

With its scope and abilities steadily expanding, MiniFAB is looking to become a more prominent figure on the global stage. Although it has collaborated with American medical device manufacturers since its inception, the Australian company is looking to make its mark on the U.S. market by exhibiting for the first time at MD&M East. "It is the biggest medical device and manufacturing fair in the world and a perfect opportunity to launch our company to [the] U.S. market," Milojevic says. "We also recognize the need to educate customers about the potential of micro- and nanotechnology in their applications, which is not necessary always obvious."

The company's involvement with a 2009 Medical Design Excellence Award-winning product, which will be honored at the trade show, provides an added incentive for the company to attend. MiniFAB developed the disposable osmolarity test card for the TearLab osmolarity system, manufactured by TearLab Corp. (San Diego). The card features a 75-µm-wide microfluidic channel designed to collect 50 nl of tears for point-of-care biomarker analysis.

MiniFAB

www.minifab.au

Booth #637

Copyright ©2009 Medical Product Manufacturing News

You May Also Like